カート

カートが空です

Weatherproof soldering butt connectors with pre-measured solder sticks and dual hot-melt adhesive rings create strong, sealed joints in seconds; these marine-grade butt connectors with solder are gauge-marked, impact-resistant and perfect for fast, reliable wiring in harsh, wet environments.

Secure Payment via:

ブランド: Haisstronica

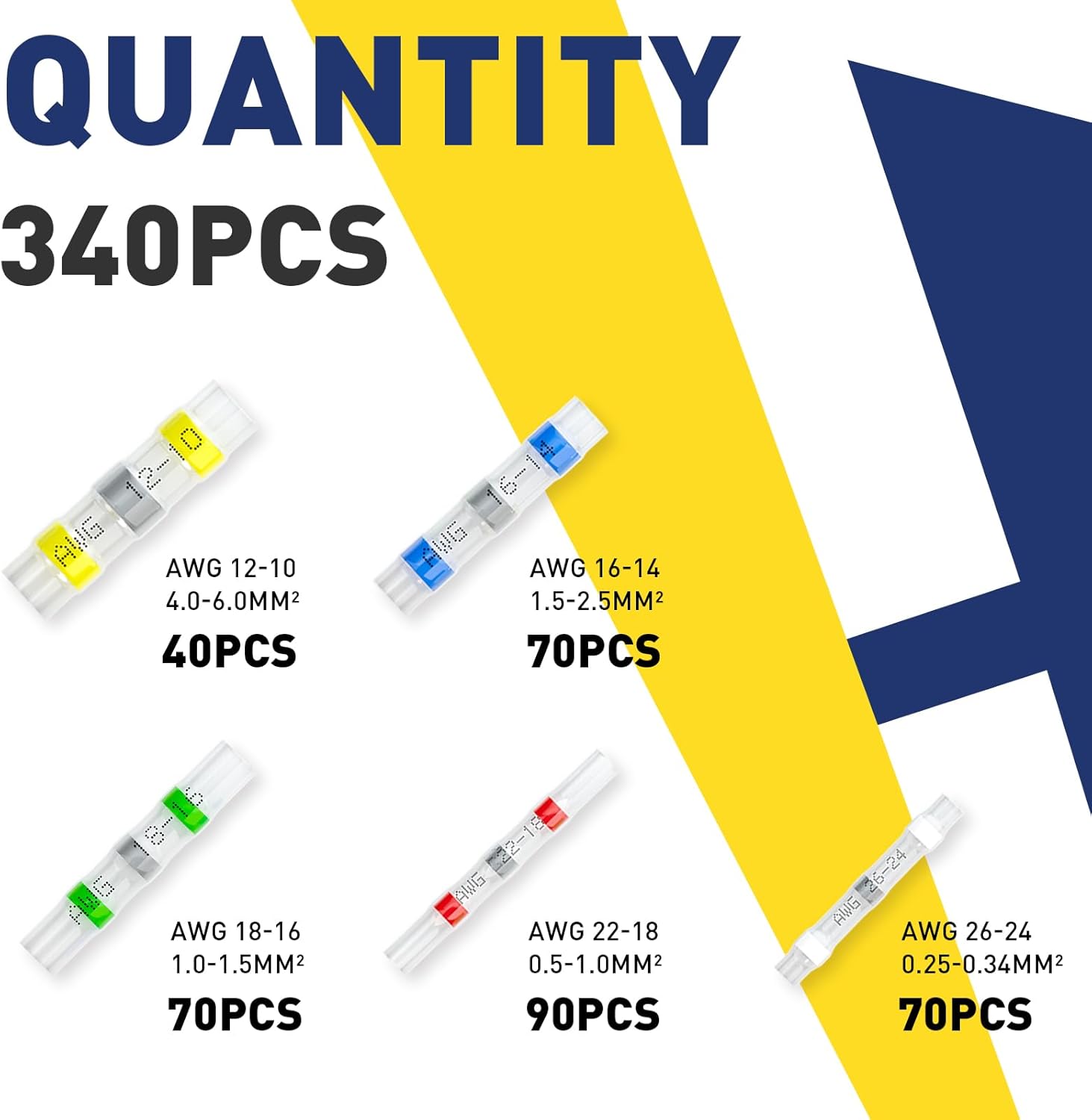

色:赤、白、黄、青、緑

AWG: 22-18、26-24、12-10、16-14、18-16

接点材質:銅

コネクタタイプ:バットスプライス

断熱材:ポリオレフィン

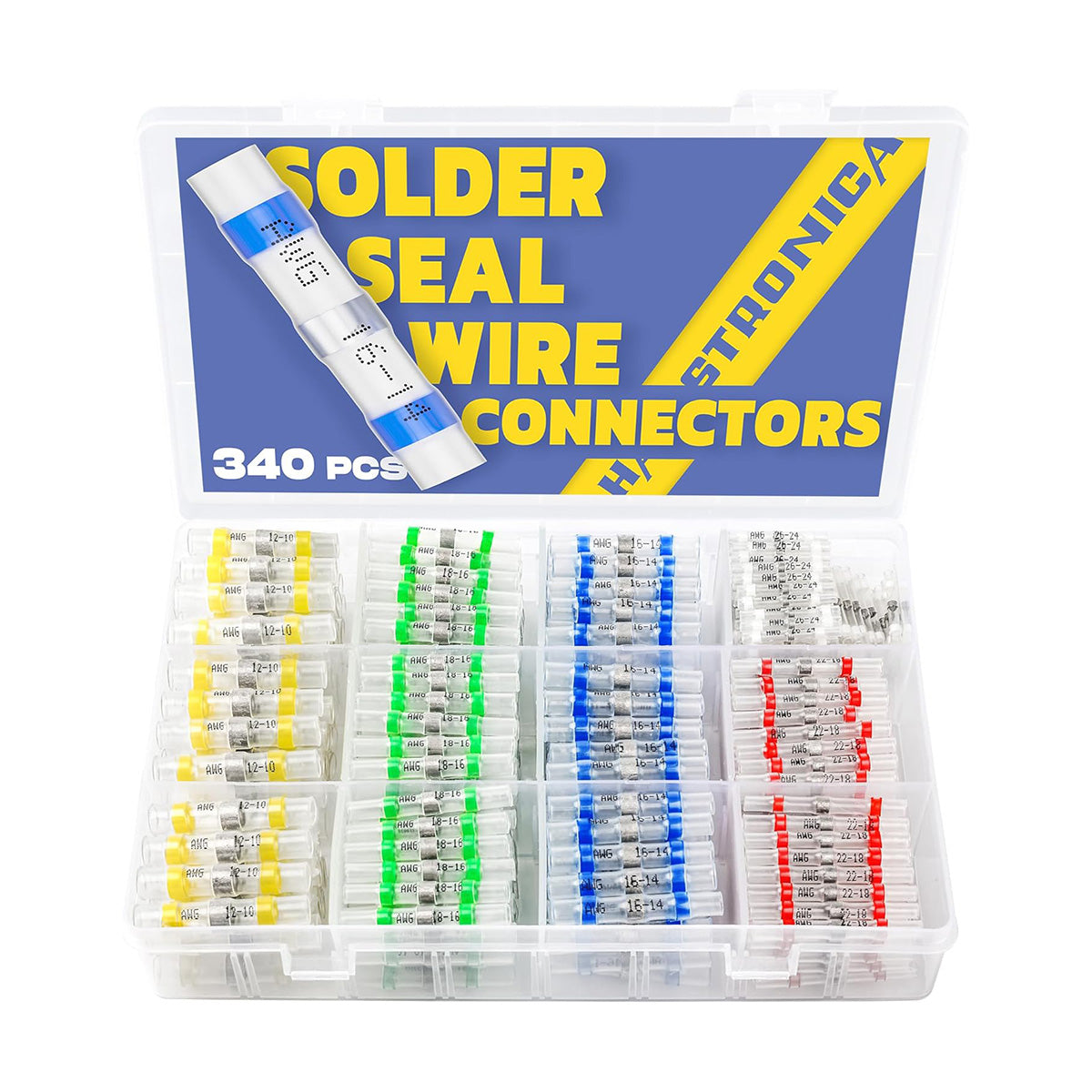

パッケージスタイル:箱入り

Haisstronica はんだシールワイヤコネクタキットを使えば、安全で防水性の高いワイヤ接続を簡単に実現できます。電気技師、自動車整備士、DIY愛好家に最適なこの包括的なキットには、はんだ付けと熱収縮絶縁を1つの使いやすいソリューションに組み合わせた、高品質のはんだ付けバットコネクタ340個が含まれています。

迅速で耐久性があり、信頼性の高い電気接続が必要な場合は、Haisstronicaの熱収縮はんだ付けコネクタが最適です。配線作業を簡素化し、効率化するために特別に設計されたこれらのコネクタは、堅牢なはんだ接合部と熱収縮チューブを組み合わせることで、完全な耐候性シールを実現します。

当社のはんだワイヤコネクタは、自動車、船舶、産業、家庭の配線プロジェクトに最適で、複雑なはんだ付けプロセスを排除し、優れた導電性と保護を常に提供します。

自動車の電気修理:

Haisstronica のはんだ付けワイヤコネクタは、車両の配線ハーネス、自動車照明、電子アクセサリの耐久性と耐振動性に優れた接続を保証します。

海洋および屋外設置:

厳しい天候や湿気にさらされるボートの配線、トレーラーの照明、屋外の電気システムには、これらの防水はんだ付けおよび熱収縮コネクタを使用してください。

家庭および DIY の電気プロジェクト:

当社のはんだシール コネクタの使いやすさと信頼性を活用して、家庭配線のアップグレード、照明の設置、電化製品の修理、趣味の電子機器プロジェクトを簡素化します。

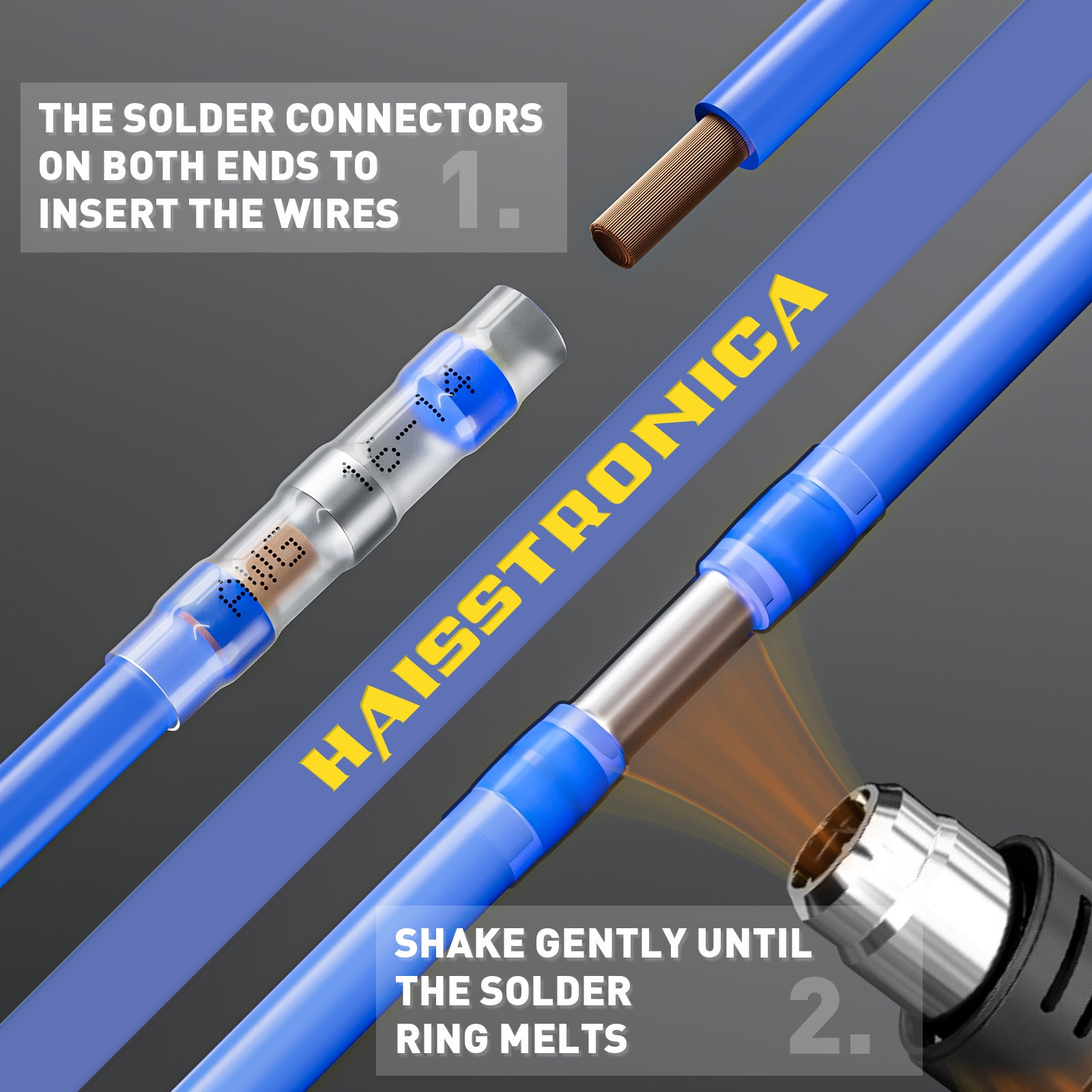

ステップ 1:被覆を剥がしたワイヤをはんだ付けコネクタの両側に挿入します。

ステップ 2:ヒートガンまたはライターを使用して均一に熱を加え、はんだを溶かしてチューブを収縮させます。

ステップ 3:接続部を冷却し、堅牢で防水性のあるはんだ接合部と絶縁シールを形成します。

特徴:

Quick Secure Connections

Perfect for outdoor projects, it keeps your connections safe from moisture and corrosion.

Guaranteed Weatherproof

Its innovative design ensures a secure bond every time, making your projects smooth and efficient.

Easy To Use & Saves Time

Save time and effort with connectors that simplify your tasks without compromising quality.

Enhanced Safety

Reduce burn & hazard risks to ensure a safer working environment, while being 100% safe for electronics.

Fits All Projects

From automotive repairs to home improvements, it’s the go-to solution for any wiring challenge.

Lasting Reliability

With high-quality materials and construction, it delivers reliable connections that stand the test of time.

When you require quick, durable, and reliable electrical connections, Haisstronica’s heat shrink solder connectors stand apart. Designed specifically to simplify and enhance wiring tasks, these connectors offer robust solder joints combined with heat-shrink tubing to ensure a completely weatherproof seal.

Perfect for automotive, marine, industrial, and home wiring projects, our solder wire connectors eliminate complicated soldering processes and deliver superior conductivity and protection every time.

Yes. These Haisstronica connectors are marine-grade butt connectors with solder, hot-melt rings and heat shrink with solder that create a fully sealed joint. Once heated, the sealed solder connectors and built-in wire sealant protect the splice from saltwater, moisture and corrosion, making them ideal for boats, trailers and other marine wiring.

The kit on is typically supplied in an organized plastic box, so your solderless electrical connectors and small parts stay sorted by size. Packaging can change over time, so check the current listing photos to confirm how this set of solderless connectors is packed.

Very easy. Each soldering butt connector is pre-loaded with low-melt solder and adhesive rings. Simply overlap the stripped wires, slide on the connector, and heat evenly with a soldering iron or heat gun. As the solder sticks melt and the tubing shrinks, you get a reliable soldering connection without crimp tools or extra flux.

The tubing and solder are designed for typical heat shrink soldering temperatures. Just heat until the inner ring flows and the tube fully contracts—well above the solder melting point but below the level where the sleeve would scorch. You don’t need to dial in an exact soldering iron temperature; use a controlled heat gun and avoid open flame for best results.

Shoppers often highlight how quick these solder seal connectors are to use and how well the joints hold up in wet, mobile environments. Many reviews mention clean, strong solder splices and appreciate that one connector can both solder and seal in a single step. For the latest feedback, check the review section on the product page.

Yes. Each shrink solder connector uses colored tubing (for example, red, blue, yellow, white) plus printed AWG markings so you can instantly match the right size to your wire gauge. This color coding makes it easy to seal wire correctly and avoid mixing sizes, especially when working quickly or in low-light areas.

Haisstronica offers a full line of waterproof wire connectors—our best-selling solder seal wire connectors and solder and seal wire connectors—so you can match the right piece to your job. A solder seal wire connector (also called a heat shrink solder connector, solder sleeve connector, or butt connector with solder) is used to splice two conductors and seal the joint in one step. Each piece combines a clear heat-shrink tube, a low-temperature solder ring, and dual hot-melt adhesive bands to deliver a tight, durable splice for automotive wire connectors, marine projects, and home wiring.

How it’s built and how it works: the clear EVA/polyolefin tubing lets you see soldering penetration as the alloy melts and flows; the hot-melt adhesive cools in seconds and locks out moisture; and the integrated solder sleeves create an electrically solid, long-lasting soldered connector. Slide the sleeve over stripped conductors with proper overlap, center the solder ring, then apply even heat—this is true solder and heat shrink in a single motion, no crimp required. When finished, the joint behaves like a one-piece, sealed solder connector.

For maximum strength and sealing, choose the connector by the conductor gauge—not by overall jacket thickness or extra wrap. Haisstronica prints the wire gauges directly on the tubing for quick pick-and-place selection, so you always match the right solder butt connector to the job. Clean copper strands, insert to full depth, and heat until the solder heat shrink flows and the adhesive forms continuous fillets at both ends. Selecting by true AWG and heating evenly prevents weak joints often seen with mis-sized or under-heated solder wiring connectors.

Count on Haisstronica for quality, sturdy solder connectors that secure loose ends and keep systems running. Our hot-melt system delivers the right amount of adhesive that cools, hardens, and reaches bond strength within seconds—ideal sealed connectors for field service. If you need reliable wire solder connectors that stand up to vibration, water splash, and road grime, our kits are ready. For product details and sizing help, browse our catalog of wire connectors with solder. Questions about waterproof solder wire connectors for your application? Contact us—our team is here to help.

Want deeper know-how? Read our step-by-step guides on installing heat shrink solder connectors and choosing the correct size of solder seal connector for different wire bundles. You’ll learn best practices for staggering splices, managing strain, and routing solder wire connections in tight spots—techniques that make shop or roadside repairs as fast as bench work.

There are three common splice styles in our range: 1) straight solder butt connectors for end-to-end joins; 2) ring and spade solder terminals for panel terminations; and 3) inline solder splice connectors for multi-segment repairs. Your application drives the choice. For critical or wet locations, always use crimp and seal connectors or our solder & seal sleeves that combine electrical continuity with an adhesive-lined barrier. Avoid plain solderless connectors where a watertight joint is required.

What’s inside matters. Our tubing is abrasion-resistant EVA/polyolefin for long-term reliability; the transparent body confirms full wire connector solder flow; and the adhesive bands act as a true wire sealer. Compared with simple heat-shrink alone, the integrated alloy creates a robust solder wire splice that won’t wick moisture or loosen under vibration—exactly what you want in automotive wire connectors kit repairs, boat wiring, and outdoor installs.

To achieve the designed performance, use the minimum connector count for the route and heat each piece to full activation—the solder must liquefy and the ends must seal. Space splices to avoid concentrated bending, and let the joint cool before loading. Following these steps allows the assembly to reach its intended efficiency, the same way torque is essential for mechanical hardware.

Finish options in our line address real-world conditions. Choose color-coded sizes for quick identification, or reach for assorted kits when servicing mixed harnesses. Whether you’re shopping solder stick connectors, compact quick solder connectors, or full solder wire connector kit assortments, you’ll find the right match for repair benches, trail bags, and service trucks.

Haisstronica stands behind every connector. If you’re not satisfied, reach out—our quality commitment means we’ll make it right. When your project demands best waterproof solder wire connectors that combine electrical integrity with a dependable shrinkable seal, choose Haisstronica solder seal wire connectors for results that last.