Why Cold Weather Makes Sealing So Hard

Cold weather can wreak havoc on electrical connections, especially when you're trying to ensure tight, durable seals. The primary issue is the way materials behave in low temperatures. Heat-shrink tubing, which is commonly used to insulate and seal connections, requires heat to shrink tightly around the wire. But in freezing conditions, the tubing can become brittle and resistant to shrinking properly. It may not form the seal you need, leaving your connections vulnerable to moisture, dirt, and other contaminants that can lead to corrosion or short circuits .

In addition to material behavior, cold weather makes the installation process more difficult. Tools and connectors can become stiff and harder to manipulate, making it challenging to achieve a secure connection. Without the right components, the job can turn into a nightmare, especially in outdoor environments like RVs, boats, or areas prone to freezing temperatures. That’s why choosing the right sealing connectors and heat shrink tubing that can withstand freezing temperatures is essential for any outdoor or automotive wiring project during the winter months.

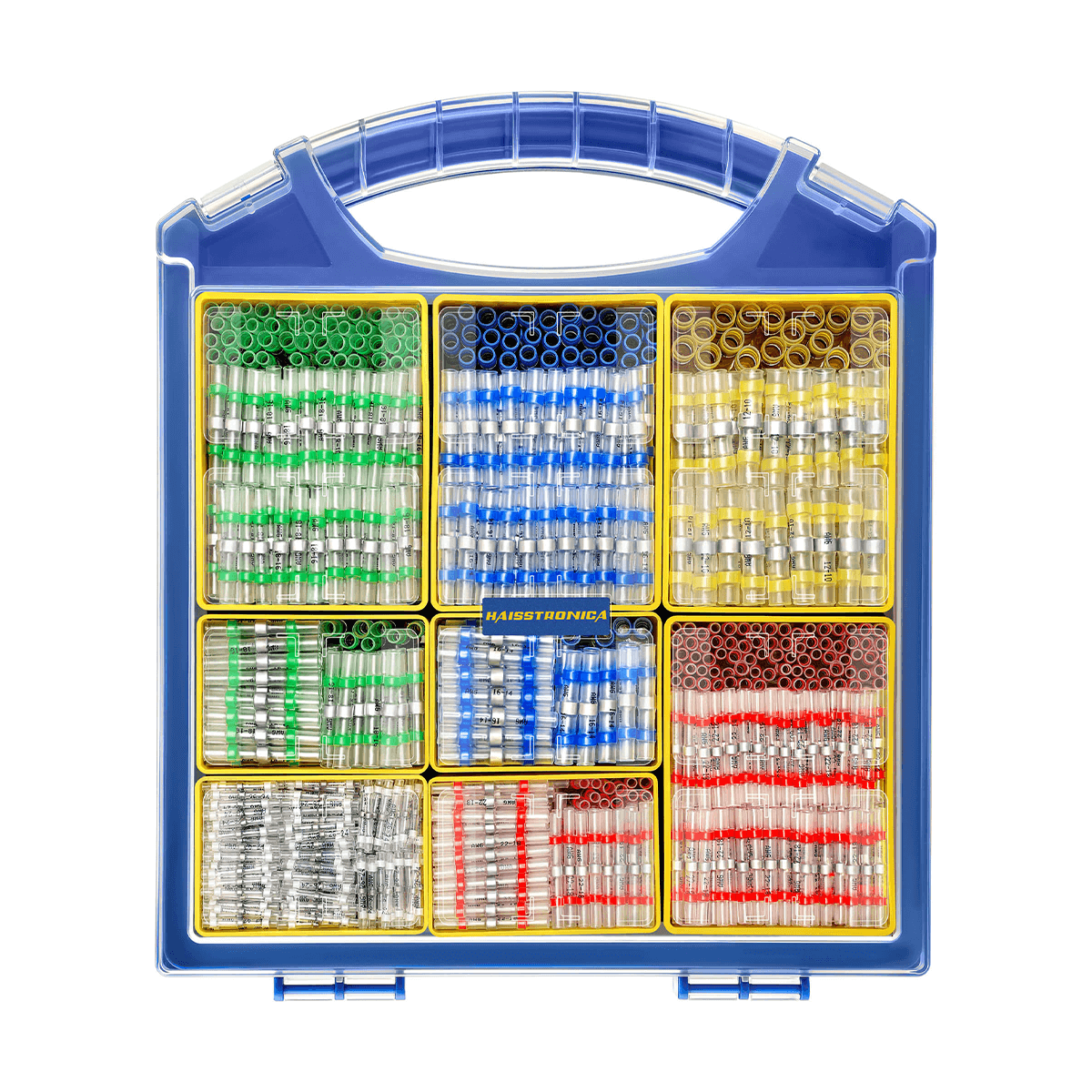

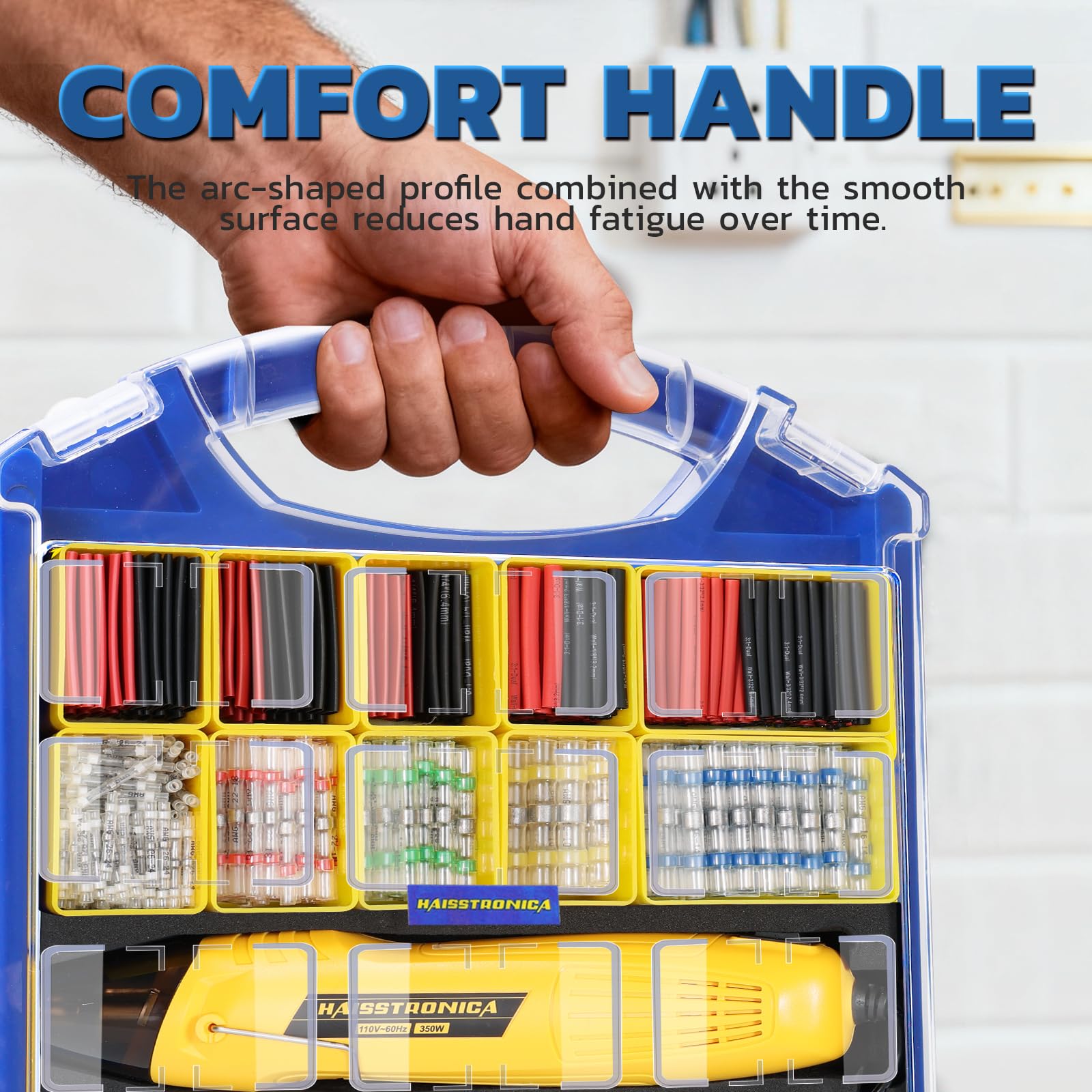

When you work in cold weather, the added strain on electrical connections means that poor seals and improper installation are more likely to result in failures. Solder & seal connectors and other specialized products, like solder shrink sleeves, are designed to meet the challenge of cold-weather wiring. These connectors are engineered to maintain their integrity in temperatures far below freezing, providing secure seals and reliable electrical connections. (For the best quality heat shrink solder sleeves that perform reliably in cold environments, check out Haisstronica’s product selection – ideal for soldering connections in harsh conditions.)

Know Your Temperature Window

When selecting products for cold-weather electrical installs, understanding the temperature window for your connectors and tubing is crucial. Every material has a specific range of temperatures at which it remains flexible and effective. If you don’t take this into account, you could find your seals cracking or failing after installation.

Temperature Ranges for Connectors and Tubing

For example, heat-shrink solder wire connectors have a shrink temperature that typically ranges from 100°C to 120°C (212°F to 248°F), but the material itself needs to remain flexible enough to wrap around the wire properly before heat is applied. In colder climates, this can be a challenge, as the tubing will not shrink properly at low temperatures. Solder splices, which combine heat-shrink tubing with internal solder, are designed to melt at lower temperatures (around 138°C to 150°C or 280°F to 302°F), but they still need to be properly heated for the best performance.

Haisstronica’s heat-shrink solder sleeves are crafted to meet high standards for durability, even in low temperatures, by ensuring the solder melts evenly and adheres properly to the wire. These connectors are great for applications in outdoor landscape lighting wire systems, automotive wiring, and marine setups, where you need a waterproof, sealed connection that won’t fail in freezing conditions. The key is ensuring that the solder and adhesive inside the sleeve can effectively activate and form a secure connection even in sub-zero temperatures.

In comparison, if you use solderless wire connectors in cold weather, they still perform reliably without the need for heat to activate them. However, these connectors require careful attention to how well the wires are crimped, as crimp and seal connectors are only effective if the crimp is tight and the seal is applied properly. (Haisstronica offers automotive wire connectors kits that include a variety of sizes, perfect for outdoor winter wiring needs. They ensure a tight crimp and reliable seal that resists freezing temperatures.)

What to Buy: Connector & Tubing Choices That Work in the Cold

When selecting connectors for cold-weather installs, you need to prioritize quality, durability, and temperature resistance. Here’s a quick guide on the best products for ensuring reliable seals in freezing conditions.

1. Shrink Solder Connectors

The most reliable choice for cold weather is shrink solder connectors. These are designed to handle extreme temperatures by combining soldering connections with shrink tubing, making them highly effective for electrical splices that need both protection and strength. When heated, the solder melts, creating a strong bond between the wires, and the heat-shrink tubing forms a protective layer that insulates and seals the joint. Solder seal butt connectors are ideal for cold-weather applications like outdoor lighting or automotive wire connections, where high vibration and exposure to moisture or freezing temperatures are common. The solder wire splice inside these connectors ensures a solid electrical connection, and the added shrink tube prevents corrosion and water infiltration, making them the top choice for wire sealing.

2. Heat Shrink Solder Wire Connectors

Similar to solder connectors, heat-shrink solder wire connectors are designed to provide a professional-quality splice that resists environmental conditions, including moisture and temperature extremes. These are perfect for projects that require a simple, yet effective, waterproof connection. They offer an added benefit by providing both the soldering process and insulation in one step. Haisstronica’s solder shrink sleeves are ideal for wiring exposed to harsh weather, like marine electrical connectors, providing a waterproof, sealed connection that holds up even in sub-zero climates.

3. Solderless Crimp Connectors

While solderless wire connectors are an excellent choice for quick installations, in cold weather, you need to be extra cautious about the crimp quality. Sealed connectors with a crimp and seal design (like Haisstronica’s crimp terminals) offer the best of both worlds. These connectors offer a mechanical bond that resists vibrations, and the heat-shrink component adds an extra layer of insulation. Whether it’s a butt crimp connector or a spade terminal, these sealed wire connectors ensure that your electrical connections stay safe and reliable even when exposed to freezing temperatures.

4. Heat-Shrink Tubing

For simple insulation needs, heat-shrink tubing can also be effective in cold weather if the tubing is rated for low temperatures. The right tubing will shrink evenly at the right temperatures and provide a tight, moisture-proof seal around the wire joint. Haisstronica’s heat-shrink solder sleeves come in a variety of gauges and materials, ensuring that you can find the right fit for your outdoor wiring needs, from landscape wiring to marine electrical wiring.

By selecting quality solder splices and solder shrink sleeves, you ensure that your connections maintain their integrity, even in the harshest weather. The adhesive-lined shrink tubing on these connectors provides additional benefits, especially when used in outdoor landscape lighting or other exposed applications.

Conclusion

Cold weather can be tough on electrical connections, but choosing the right connectors and tubing can make a world of difference. Shrink solder connectors and heat-shrink solder wire connectors are both excellent options for sealing wires in freezing temperatures, as they provide durable, waterproof seals that protect the electrical joints from corrosion and damage. Whether you’re working on automotive wiring, landscape lighting, or any outdoor wiring project, solder & seal connectors offer a reliable, easy-to-use solution for cold-weather installations. With the right tools and materials, including heat shrink solder sleeves and solderless wire connectors, you can ensure that your wiring will withstand even the harshest conditions.

Get the best solder and seal connectors for your project by shopping with Haisstronica – your go-to source for high-quality electrical connectors that perform in any season. Whether you need solder splices, solder wire splices, or sealed connectors, we’ve got you covered for every wiring need.