Panier

Votre panier est vide

Secure Payment via:

Marque : Haisstronica

Poids de l'article : 1,2 livre

Dimensions du colis : 10,87 x 4,25 x 1,02 pouces

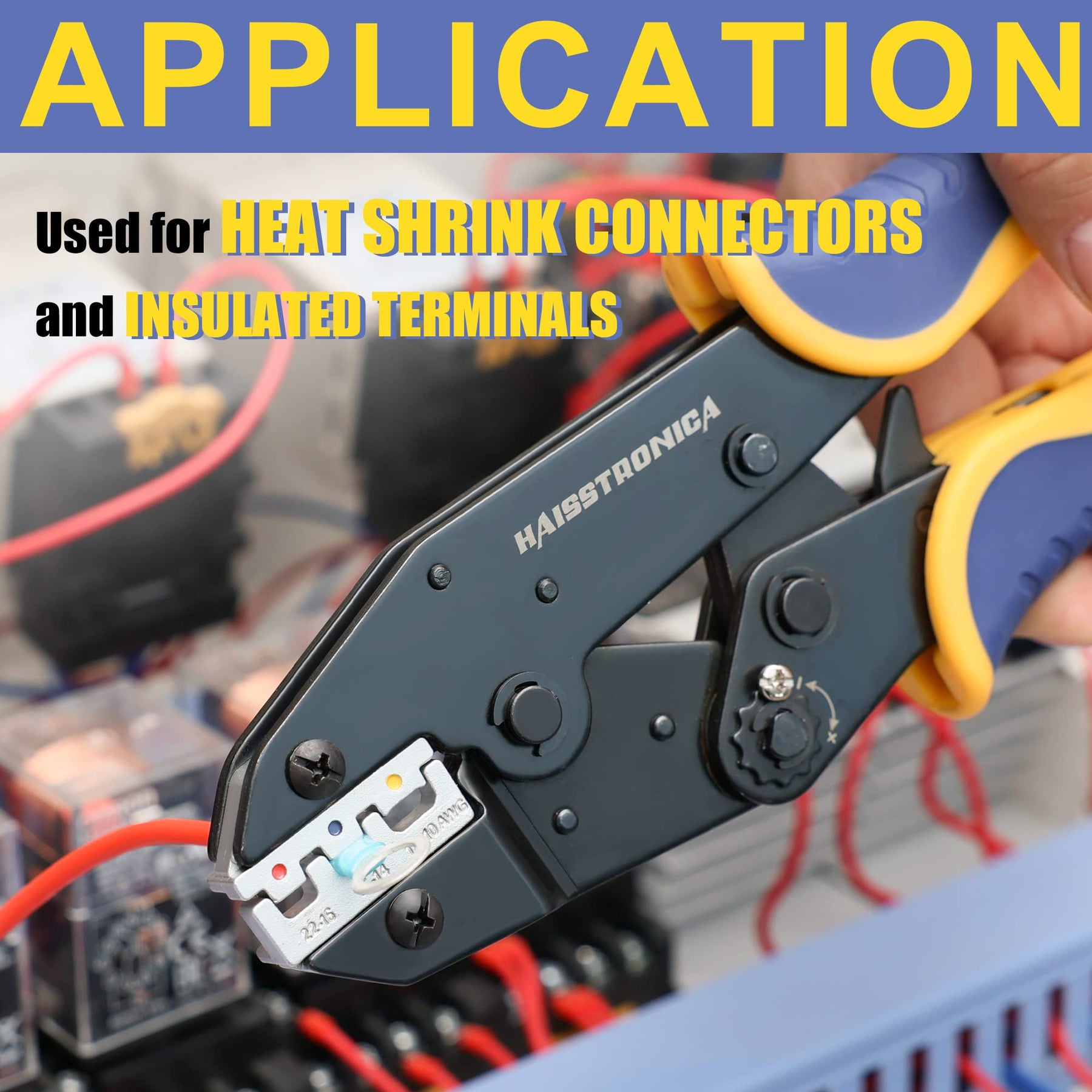

La pince à sertir à cliquet Haisstronica est un outil de précision spécialement conçu pour un sertissage sûr et professionnel des fils de calibre AWG 22 à 10. Parfaitement adaptée aux connecteurs thermorétractables, cette pince polyvalente assure un sertissage fiable et constant. Idéale pour les électriciens, les techniciens automobiles et les bricoleurs passionnés, cette pince robuste allie simplicité d'utilisation, durabilité supérieure et la qualité reconnue de Haisstronica, simplifiant considérablement vos tâches de câblage.

Cette pince à sertir de qualité professionnelle offre des avantages exceptionnels dans de multiples applications :

Gagnez un temps précieux sur le chantier et assurez des sertissages précis à chaque utilisation. Le mécanisme à cliquet fiable assure une pression uniforme, garantissant des connexions constantes et de haute qualité. Contrairement aux outils de sertissage classiques, cet outil de sertissage spécialisé Haisstronica garantit des sertissages précis, réduisant ainsi les retours en arrière dus à des connexions desserrées ou défectueuses. Indispensable pour les panneaux de câblage, les boîtes de jonction et les installations de prises.

Gérez sans effort les installations, réparations et personnalisations de câblage automobile grâce à cette pince à sertir fiable. Ses mâchoires précises sont compatibles avec les calibres de câblage automobile courants (AWG 22-10), garantissant des connexions solides et résistantes aux vibrations, idéales pour les installations d'électronique, d'éclairage et de systèmes audio automobiles. Sa conception ergonomique rend le sertissage répétitif des fils confortable et efficace, accélérant considérablement chaque projet automobile.

Intuitif et facile à utiliser, cet outil de sertissage de fils rend les projets domestiques accessibles, même aux débutants. Réalisez des connexions de qualité professionnelle sans effort pour des tâches telles que la réparation d'appareils électroménagers, l'installation de home cinéma, l'électronique amateur et les projets de câblage DIY. Finies les frustrations et les incertitudes grâce à des sertissages de fils propres et sûrs à chaque fois.

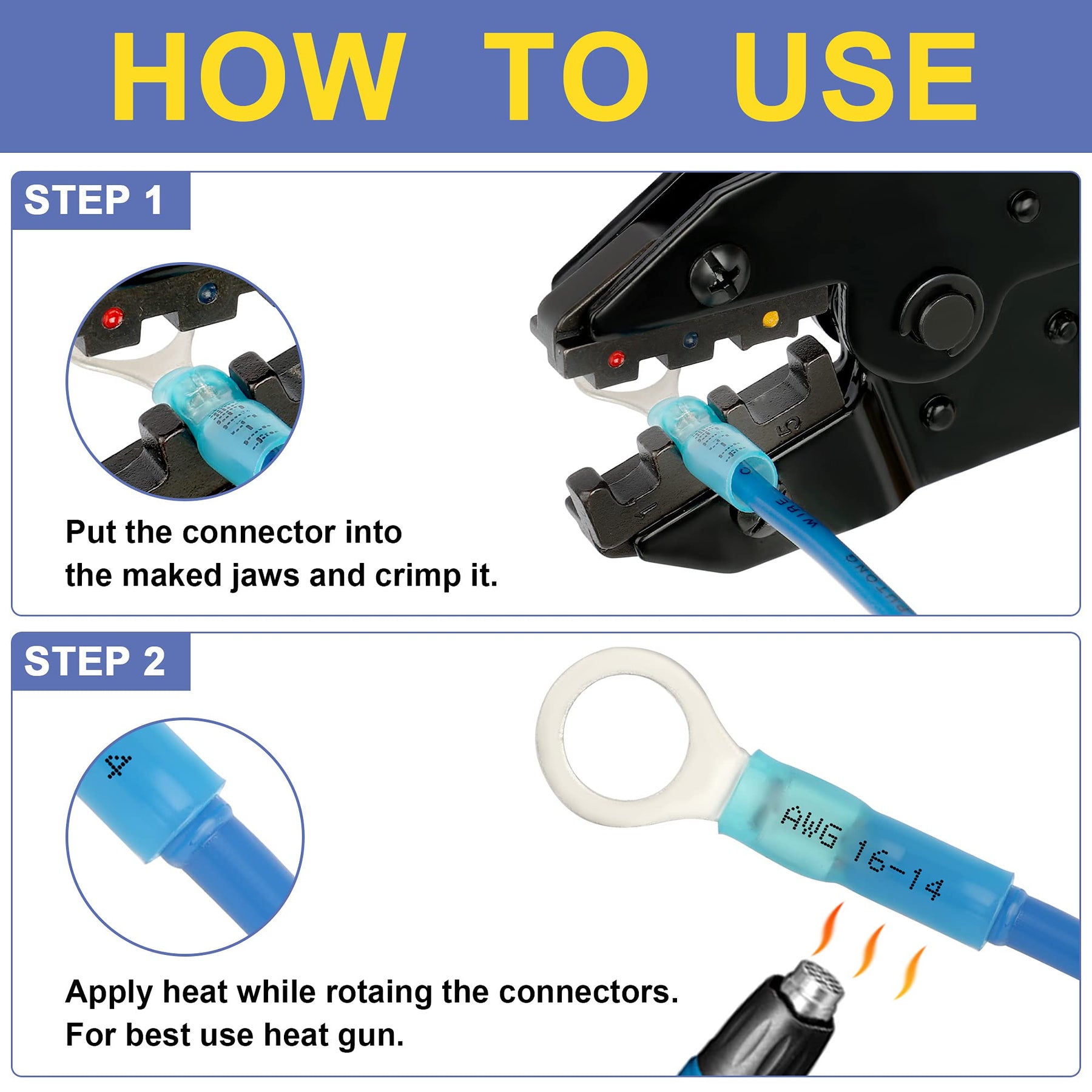

Préparez les fils : dénudez vos fils et insérez-les complètement dans un connecteur thermorétractable approprié.

Positionner le connecteur : Placer fermement le connecteur dans les mâchoires de sertissage.

Sertissage sécurisé : Pressez les poignées jusqu'à ce que le cliquet se libère automatiquement, assurant ainsi un sertissage parfait du fil .

Inspectez et terminez : inspectez votre sertissage sécurisé et fiable et rétractez à chaud le tube du connecteur pour réaliser une connexion étanche et isolée.

Caractéristiques:

Très belle qualité de fabrication, l'outil de sertissage à cliquet fonctionne en douceur et sertit parfaitement.

Cette pince à sertir à cliquet est d'une efficacité redoutable. Elle permet un sertissage solide et uniforme. Le cliquet de la pince se déverrouille facilement une fois le sertissage terminé et, si vous devez repositionner l'élément avant la fin, un système de déverrouillage est disponible. Solide !

Je ne peux pas recommander suffisamment ce cliquet à sertir !!!!! Il serre parfaitement les connecteurs thermorétractables.

This professional-grade wire crimper offers exceptional benefits across multiple applications:

Sertissage de précision

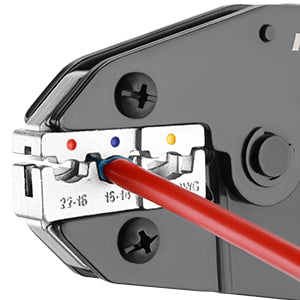

Le cliquet de l'outil de sertissage calibré applique une pression uniforme sur tout le canon pour une déformation uniforme, une forte conductivité et une résistance à l'arrachement supérieure.

Roue de compression réglable

Avec les outils de sertissage à cliquet , la molette de réglage assure une compression constante sans couper l'isolation, améliorant la fiabilité et réduisant les retouches sur les projets automobiles, marins et domestiques.

Dégagement rapide

Si l'alignement n'est pas parfait ou si un connecteur se déplace au milieu du sertissage, le loquet d'urgence vous permet d'ouvrir en toute sécurité l' outil de sertissage à cliquet avant la fin du cycle.

Oui, les faisceaux automobiles sont parfaitement adaptés. Une pince à sertir à cliquet permet de réaliser des terminaisons résistantes aux vibrations et étanches au gaz pour les capteurs, l'éclairage, l'alternateur et les câbles de démarreur. Grâce aux pinces à sertir à cliquet, vous obtenez une compression complète à chaque fois, essentielle en cas de chaleur et de chocs. Veillez à bien dénuder les fils et à utiliser un serre-câble approprié, et le sertissage à cliquet permet d'éviter les pannes intermittentes et les chutes de tension.

Idéal pour les débutants. Les pinces à sertir à cliquet bloquent les mâchoires jusqu'à ce que la compression souhaitée soit atteinte, vous permettant ainsi de vous concentrer sur le positionnement et la longueur de dénudage plutôt que sur la force de préhension. Grâce aux cavités à code couleur des pinces à sertir à cliquet , la taille du fil est indiquée. Comparé à un outil de sertissage classique, vous obtiendrez des résultats reproductibles et faciles à inspecter après une courte séance d'entraînement.

Minimal. Gardez votre pince à sertir à cliquet propre et sèche ; essuyez les mâchoires, ajoutez une goutte d'huile légère sur le pivot et rangez-la légèrement fermée. Inspectez les matrices de la pince à sertir à cliquet pour déceler toute trace d'usure ou de bavure et remplacez-les si elles sont endommagées. Des pinces à sertir bien entretenues maintiennent des hauteurs de compression précises, réduisant ainsi les risques d'arrachement et les reprises sur des centaines de terminaisons.

Absolument. Une pince à sertir à cliquet est tout aussi efficace pour l'électronique marine, les câbles d'équilibrage solaire, l'audio domestique, les commandes CVC et les capteurs industriels. Associée aux bornes appropriées, une pince à sertir à cliquet assure des connexions conformes aux normes dans les installations humides, vibrantes ou stationnaires. Choisissez la matrice et la famille de connecteurs adaptées à chaque application, puis utilisez l' outil de sertissage correctement.

Oui, adaptez le calibre à la cavité de la matrice. Avec une pince à sertir à cliquet , les bandes de couleur correspondent généralement à la section AWG 22-10 pour les connecteurs isolés courants. Changez ou ajustez les matrices de la pince à sertir à cliquet lorsque vous changez de style de connecteur. Consultez le tableau du produit ; un cycle de sertissage à cliquet constant garantit un profil de compression approprié et une résistance à la traction fiable pour toutes les tailles.

Principalement multibrins. Une pince à sertir à cliquet et un outil de sertissage à cliquet pour cosses isolées sont conçus pour les conducteurs multibrins, qui se déforment pour remplir le fût. L'âme massive ne peut fonctionner qu'avec des connecteurs homologués pour conducteurs massifs ; sinon, utilisez des cosses à vis ou à compression. Si nécessaire, une pince à sertir à cliquet non isolée avec la matrice appropriée peut convenir.

Oui, choisissez du cuivre étamé, des cosses thermorétractables avec revêtement adhésif et des pinces en acier inoxydable. Les pinces à sertir à cliquet assurent une compression uniforme pour une étanchéité optimale ; respectez les longueurs de dénudage indiquées par le fabricant. Une pince à sertir à cliquet permet de réussir les tests d'arrachement après cycles thermiques et vibrations. Pour les zones difficiles d'accès, un outil de sertissage à cliquet et des matériaux de qualité marine améliorent considérablement la longévité.

Cela dépend de la puissance du connecteur, et non de l'outil. Les pinces à sertir à cliquet résistent à la chaleur, mais il est impératif de les utiliser avec des cosses haute température (par exemple, des câbles nickelés en PTFE). Pour les faisceaux de câbles de compartiment moteur, une pince à sertir à cliquet pour cosses non isolées avec contacts à corps ouvert correspondants est courante. Vérifiez toujours la classe d'isolation avant d'utiliser un outil de sertissage.

Polyvalente. Une pince à sertir à cliquet pour cosses isolées gère les épissures bout à bout, les cosses à anneau, les fourches, les cosses plates et les déconnexions rapides. Avec les matrices adaptées, une pince à sertir à cliquet peut également réaliser des sertissages et des embouts OEM à fût ouvert. Votre pince à sertir doit être compatible avec la famille de connecteurs ; ne mélangez jamais des matrices et des fûts qui ne sont pas conçus pour être utilisés ensemble.

Vérifiez le modèle spécifique. De nombreux outils à sertir isolés à usage général couvrent les calibres AWG 22 à 10 ; cette plage convient à la plupart des circuits de véhicules et d'équipements. La meilleure pince à sertir à cliquet pour cosses plus larges propose des matrices séparées jusqu'à AWG 6 à 4, voire plus. Consultez le tableau de votre pince à sertir à cliquet et effectuez un cycle de sertissage complet pour vérification.

Haisstronica offers more than just connectors—we also build the tools that make every crimp electrical connection clean, repeatable and strong. Our ratcheting crimper tool is a purpose-built solution for heat-shrink terminals and other electrical crimp connectors, so you can crimp, lock and move on with confidence. Whether you’re wiring a boat, refreshing automotive harnesses or upgrading appliances, this crimping tools for wire set gives you a consistent, “like-solder” bite without guesswork.

How it’s built and how it works: the steel frame and precision crimping dies turn hand force into a controlled hex-style compression that wraps the barrel evenly around the conductor. The internal crimping tool ratchet mechanism only releases once the crimp reaches design pressure, so every squeeze of this ratcheting crimper tool produces the same reliable result. Color-coded AWG markings guide you to the right nest for each terminal, from standard butt connectors to ring, spade and flag styles—ideal as a primary terminal wire crimper in any electrician’s kit.

Control and comfort are central to the design. The ergonomic handles on this crimper tool electrical give you leverage without strain, while the quick-release lever lets you open the jaws at any point in the cycle if you need to reposition a terminal. That means smoother ratchet crimping, fewer mis-crimps, and less fatigue during long days of crimping wires to connectors. Paired with Haisstronica heat-shrink terminals, the tool acts as a precise butt connectors crimper that delivers tight, vibration-resistant terminations for marine, RV and 12V projects.

Versatility is built in. Use it as your go-to electrician crimper for insulated and non-insulated lugs, as a wire terminal crimpers solution for control panels, or as an mc4 connector crimp tool for solar installs. From ring and spade lugs to inline splices, flag terminals and more, this single body replaces multiple electrical crimpers and wire crimping pliers, simplifying your toolbox while upgrading your finish quality. Wherever a clean electrical wire crimp or neat wire ends crimp is required, Haisstronica ratchet wire crimpers are ready.

As with all Haisstronica tools, this crimpers tool is backed by responsive support and a satisfaction guarantee. If your ratchet crimper ever fails to meet expectations, our team is here to help with troubleshooting, replacement or upgrade advice. When your work demands professional-grade crimping electrical performance and long-lasting terminations, reach for the Haisstronica ratchet crimper tool and experience the difference a true, engineered ratcheting crimping tool makes.