Pourquoi les connecteurs de fils échouent-ils dans des environnements à haute température ?

Avant d’aborder les solutions, il est essentiel de comprendre les causes profondes des défaillances des connecteurs :

- Inadéquation de dilatation thermique : différents matériaux (par exemple, métal et plastique) se dilatent/se contractent à des rythmes différents, provoquant des fissures ou des connexions lâches.

- Oxydation et corrosion : La chaleur accélère l’oxydation, dégradant les surfaces de contact et augmentant la résistance.

- Dégradation des matériaux : les plastiques et adhésifs standard peuvent fondre, se ramollir ou perdre leur intégrité structurelle.

- Dissipation thermique insuffisante : une mauvaise conception emprisonne la chaleur, accélérant ainsi l’usure.

6 stratégies pour éviter les pannes de connecteurs de fils à haute température

1. Sélectionnez des connecteurs résistants aux températures élevées

Matériaux clés :

- PTFE (Polytétrafluoroéthylène) : Résiste jusqu'à 260°C, offre une excellente résistance chimique.

- Caoutchouc Silicone : Flexible à haute température (jusqu'à 300°C), résistant aux chocs thermiques.

- Viton (Fluorocarbone) : Idéal pour les carburants et les huiles, résiste à une utilisation continue à plus de 200°C.

Recommandation de produit :

- Connecteurs Hi-Temp X90 (certifiés UL pour 250 °C)

- Borniers gainés de silicone

2. Optimiser la conception des connecteurs pour la gestion thermique

- Caractéristiques de dissipation thermique : utilisez des ailettes, des dissipateurs thermiques ou des matériaux conducteurs thermiquement (par exemple, des alliages d'aluminium).

- Conception modulaire : permet une inspection et un remplacement faciles des composants soumis à de fortes contraintes.

- Ligne de fuite : Augmentez l'espacement entre les conducteurs pour éviter la formation d'arcs (conformément aux normes IEC 60664).

Exemple : Les connecteurs automobiles avec ailettes de refroidissement intégrées réduisent les températures de jonction de 30 %.

3. Appliquer des revêtements de protection thermique

- Revêtements conformes : les revêtements en silicone ou en acrylique protègent les connecteurs de l'humidité et de la dégradation thermique.

- Contacts en aluminium anodisés : améliore la résistance à l'oxydation dans les applications aérospatiales.

Lien interne : En savoir plus sur nos revêtements anticorrosion

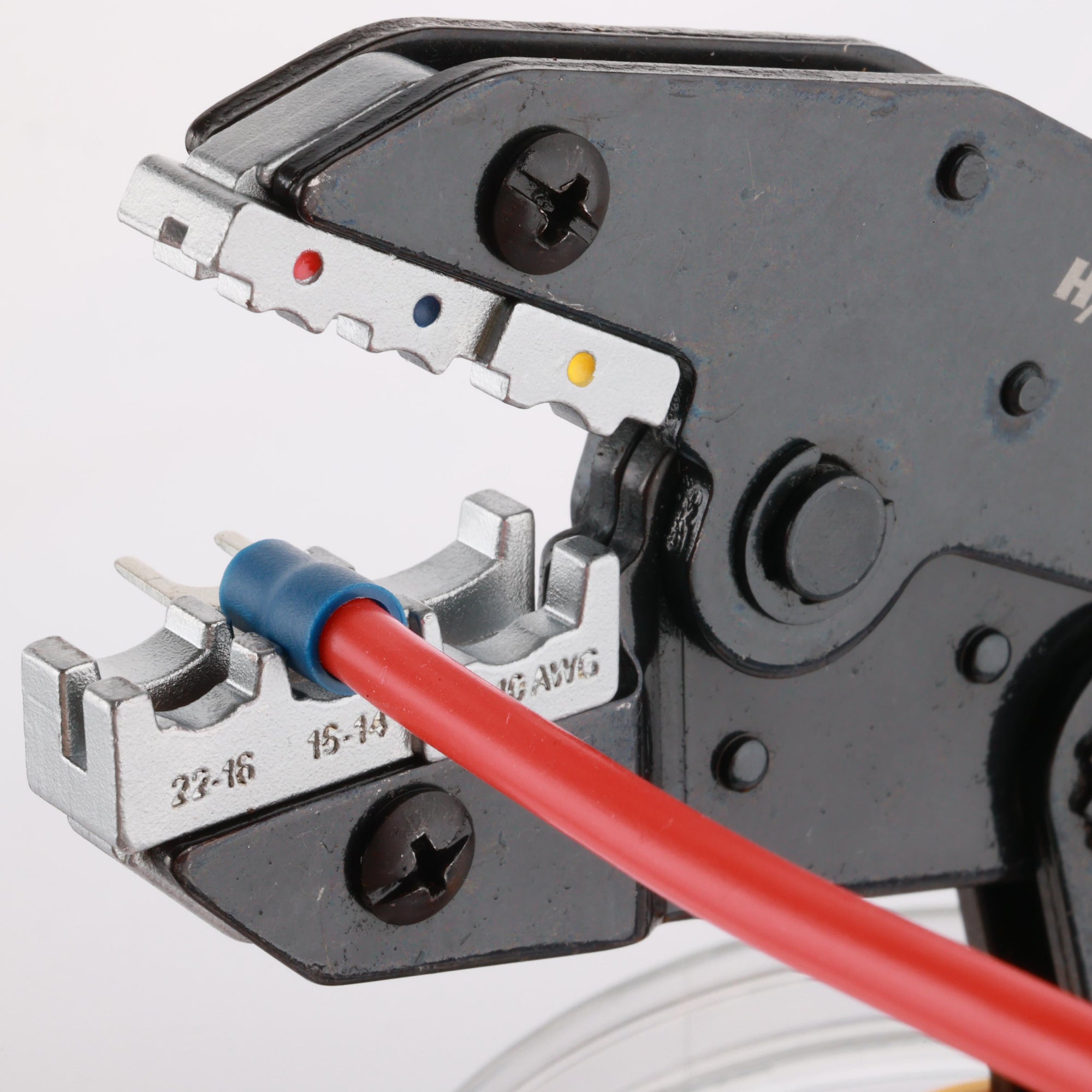

4. Assurez-vous de bonnes pratiques d'installation

- Contrôle du couple : un serrage excessif déforme les contacts ; utilisez des clés dynamométriques conformes aux spécifications du fabricant.

-

Gaine thermorétractable : scellez les connexions avec une gaine haute température (conçue pour 200 °C et plus).

- Conseil de pro : utilisez des tubes doublés d’adhésif pour une meilleure résistance aux vibrations.

Aide visuelle : inclure un schéma montrant l’application correcte et incorrecte du couple.

5. Entretien et inspection réguliers

- Imagerie thermique : Détectez les points chauds à l'aide de caméras infrarouges lors de contrôles de routine.

- Nettoyage : Éliminez la poussière/les contaminants qui retiennent la chaleur (utilisez de l’alcool isopropylique, pas de l’eau).

FAQ :

« À quelle fréquence les connecteurs haute température doivent-ils être inspectés ? »

Annuellement dans des conditions modérées ; trimestriellement dans des conditions extrêmes.

6. Utilisez des lubrifiants haute température

Appliquer de la graisse diélectrique à base de silicone sur les contacts pour :

- Réduit les frottements lors de l'assemblage.

- Prévient l’oxydation et l’arc électrique.

FAQ (optimisé pour la recherche vocale)

Q : Puis-je utiliser des connecteurs standard dans des applications à haute température ?

R : Non, les connecteurs standard se dégradent rapidement au-delà de 105 °C. Utilisez toujours des connecteurs haute température homologués UL.

Q : Comment choisir entre les connecteurs en silicone et en PTFE ?

R : Le silicone offre une grande flexibilité ; le PTFE excelle en résistance chimique. Adapté aux exigences de votre application.

Réflexions finales

Prévenir les défaillances des connecteurs de fils dans les environnements à haute température exige une combinaison de science des matériaux , de rigueur de conception et de maintenance proactive . En sélectionnant les bons connecteurs, en optimisant les installations et en effectuant des inspections régulières, vous garantissez leur fiabilité, même dans les conditions les plus difficiles.

CTA :

- Besoin d'une solution sur mesure ? Contactez notre équipe d'ingénieurs pour prise en charge de la conception de connecteurs haute température .”