If soldering is “putting it together,” desoldering is the art of undoing your mistakes without leaving scars. Whether you’re correcting a bad joint on a PCB, replacing a connector for wires on a harness, or rehabbing an older automotive wire connectors kit, how you remove old solder matters as much as how you apply it. A good solder stick, used with the right tools and prep, can make rework feel controlled instead of chaotic—and that’s what we’re going for here.

Why Proper Desoldering Matters (and Where a Solder Stick Fits In)

When pros talk about workmanship, they rarely separate soldering and desoldering. Standards like IPC J-STD-001 and IPC-7711/7721 treat removal and rework as critical steps in making reliable solder electrical connections, not just “cleanup” after the real work. A careless desolder can:

-

Lift pads or traces right off the PCB

-

Overheat components beyond their rated solder melting point

-

Leave behind cracked joints and intermittent electrical connections

Every time you reheat a joint, you’re stressing the copper, the laminate, and the component leads. NASA/JPL’s workmanship standards explicitly call out controlled heating, proper flux usage, and gentle solder removal to avoid delamination and pad damage during rework.

A solder stick (or fresh solder wire) actually helps with proper desoldering. Adding a bit of fresh solder lowers the effective melting point of old, oxidized solder, making it flow better into a solder wick or onto the tip of a desoldering pump. Think of it as “thinning out” the old metal so it behaves predictably again.

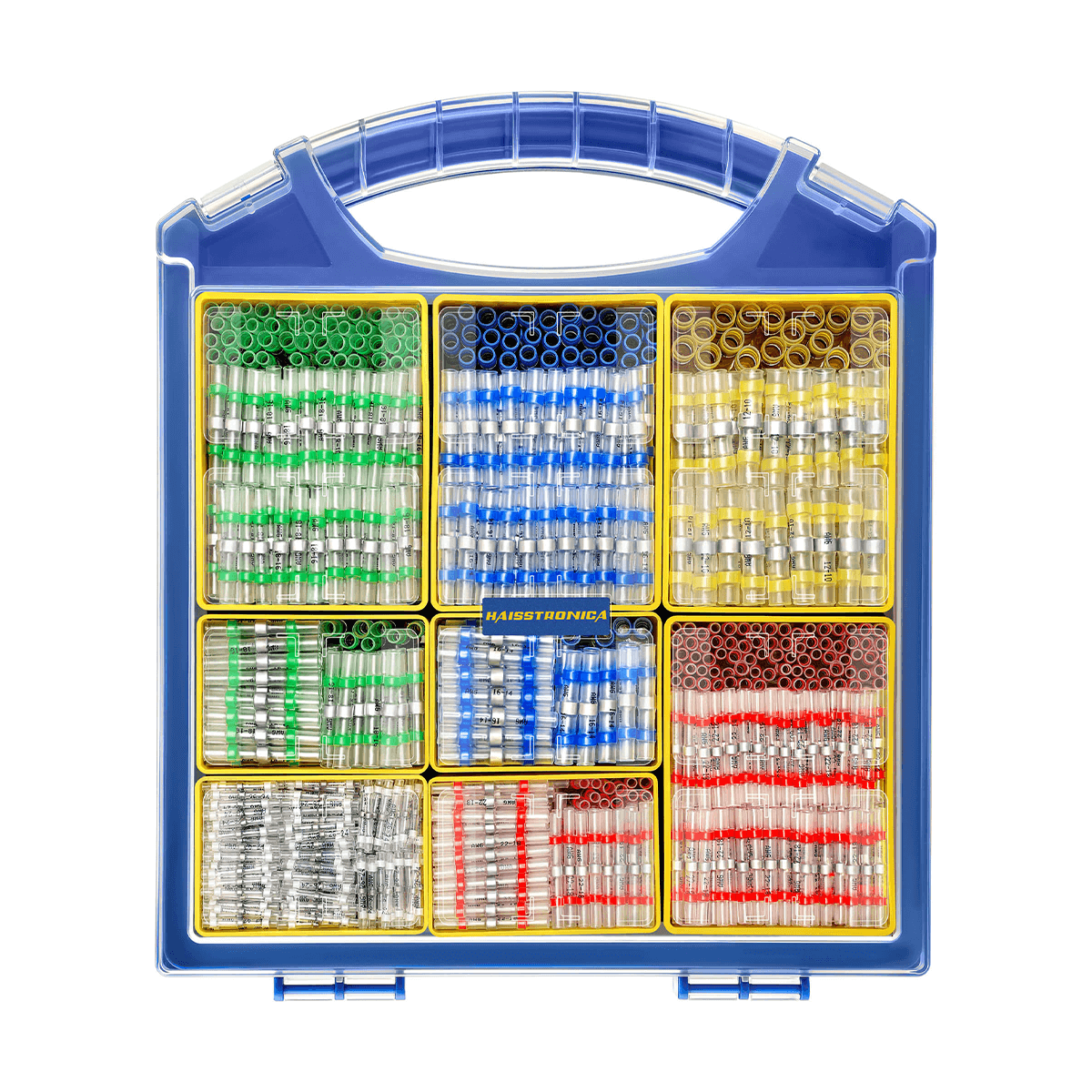

Once you’ve cleaned the joint properly, you’ll want new connections you can trust—this is where haisstronica heat shrink solder sleeves and solder splice connectors come in, letting you reassemble harnesses and leads with clean, sealed joints instead of fighting old, crusty solder.

Know Your Tools (from Solder Stick to Desoldering Gear)

Before you touch a board, get familiar with the gear that turns desoldering from a fight into a controlled process. Your solder stick is only one piece of the puzzle.

1. Heat Source: Iron or Station

You’ll want a temperature-controlled soldering iron or rework station, ideally with:

-

60–80 W of power for typical PCB and connector work

-

Replaceable tips (chisel and conical)

-

Adjustable temperature so you can match the alloy’s solder melting point (around 183 °C for common Sn63/Pb37 and 217–221 °C for many lead-free alloys).

Being able to set your iron just hot enough to reflow solder without cooking pads is essential. Too cool and you’ll dwell too long; too hot and you risk lifted pads and burned insulation. A consistent iron temperature also makes your solder & seal work more predictable when you later add heat shrink solder sleeves or butt splice solder joints.

2. Solder Removal Tools

At minimum, you should have:

-

Desoldering braid (wick): Copper braid that soaks up molten solder. A touch of flux and fresh solder stick on the tip makes it pull solder fast.

-

Desoldering pump (“solder sucker”): Great for through-hole components and large solder wire splice joints—heat, trigger, and the pump pulls molten solder off the pad.

-

Flux: Liquid or paste flux lowers surface tension and helps solder flow into the wick instead of clinging stubbornly to pads and pins.

When working near sealed wire connector systems—like automotive or marine harnesses—you might also encounter crimp and solder connectors and shrink solder connectors where the solder ring is inside a sleeve. For those, you’re not desoldering the sleeve itself, but you might be cleaning old solder off a terminal or wire before installing a new connector.

3. Consumables: Solder Stick and Friends

This is where solder stick and related consumables come in:

-

Solder stick / solder wire: Choose an alloy appropriate for your project (leaded vs. lead-free), know its solder melting point, and use small amounts to refresh old joints before removal.

-

Solder sleeves / heat shrink solder sleeve: For field wiring and harness work, these give you a controlled amount of solder and adhesive in one package, especially in an automotive wire connectors kit.

-

Wire sealant / electrical wire sealant: In harsh environments (marine, exterior lighting wire runs), sealing connectors and insulation wires after rework keeps moisture out and reduces corrosion.

haisstronica’s solder & seal kits combine solder sticks, heat shrink solder sleeves, and marine grade heat shrink butt connectors so you aren’t hunting for random consumables when it’s time to rebuild a connection.

Prep Work Before You Touch the Board (Solder Stick Success Starts Here)

Most desolder disasters don’t happen because someone lacked skill—they happen because someone skipped prep. Before you ever melt a solder stick, walk through this checklist.

1. Power, ESD, and Access

-

Kill the power. Unplug, disconnect batteries, and discharge any large caps where appropriate.

-

Set up ESD control. For electronics, use a grounded mat and wrist strap. Sensitive ICs don’t like static plus heat.

-

Clamp and secure. Use a PCB vise or helping-hands. Fighting the board while you desolder is how pads get ripped off.

Even if you’re working on connector for wire terminations rather than PCBs, secure the harness so you aren’t yanking on insulation wires when the solder finally lets go.

Once everything is secure and safe, you’ll appreciate having a sorted box of haisstronica sealed electrical connectors and solder terminal connectors ready to drop in as you re-terminate wires.

2. Visual Inspection and Planning

Take 30–60 seconds to really look at the joint:

-

Is it a through-hole pin, pad, or a solder splice connectors joint in a harness?

-

Is there visible damage—burnt board, cracked solder, or green corrosion near a sealed wire connector?

-

Are there nearby plastic parts that could soften while you chase the solder melting point?

Plan your moves: will you use wick, a pump, or both? Will you add a little fresh solder stick to thin out a big blob? On multi-pin parts, consider whether it’s safer to cut the component out first and desolder pins one by one.

When you replace a component or rewiring connection, haisstronica quick solder connectors and wire connectors with solder and heat shrink can save serious time versus rebuilding the entire harness from scratch.

3. Pre-Tinning and Fluxing

A pro trick from rework standards like IPC-7711/7721 and NASA workmanship guides is to add a bit of fresh solder before you remove the old stuff.

-

Apply flux to the joint.

-

Touch in a small amount of fresh solder stick or solder wire.

-

Let the alloy fully reflow so old and new solder mix.

This fresh solder improves heat transfer and lowers the effective solder melting point of the oxidized metal, making it much easier to pull off with wick or a pump. You’ll get cleaner pads and spend less time blasting the board with heat.

When you’re done, you can rebuild the joint using haisstronica solder wire terminals, solder ring terminal parts, or marine grade heat shrink butt connectors to ensure the new connection is as clean as the one you just removed.

4. Step-by-Step Desoldering Technique

Now you’re ready to actually move metal:

-

Heat the joint, not just the solder stick.

Place the iron tip where the lead and pad meet, then add a touch of solder so you see everything go shiny. -

Apply wick or pump.

-

For wick: place braid between tip and joint, let the solder flow into it, then lift both together.

-

For pump: heat the joint, get everything molten, then trigger the pump so it pulls solder away.

-

-

Remove heat promptly.

Don’t linger; as soon as the solder flows into the wick or disappears into the pump, move off the pad. -

Inspect and repeat if needed.

If there’s still a ring of solder, add flux and repeat. Don’t pry; if you’re pulling hard, there’s still solder holding something. -

Clean the area.

Use isopropyl alcohol and a lint-free swab to remove flux and check that pads and barrels are intact.

This same mindset applies when you’re cleaning a wire end that was inside a sealed electrical connector or a solder seal butt connectors joint: reflow, remove, clean, then rebuild with fresh solder & seal hardware.

A cleanly desoldered joint is the perfect starting point for haisstronica self soldering connectors, solder heat shrink splice joints, and other shrinkable seal solutions that give you mechanical support and environmental protection in one step.

Conclusion: Clean Desoldering Today, Easier Solder Electrical Connections Tomorrow

Proper desoldering is one of those skills that quietly decides whether your projects feel solid and professional—or like a string of near disasters. The big ideas to keep in your back pocket:

-

Treat desoldering as critical workmanship, not an afterthought. Standards from IPC and NASA hammer home that rework must protect pads, traces, and long-term reliability.

-

Use your solder stick strategically. A little fresh alloy and flux can make old joints flow cleanly instead of fighting you.

-

Get the right tools around the joint: wick, pump, flux, and if you’re working on wiring, high-quality sealed connectors and heat shrink solder sleeves for the rebuild.

-

Prep is everything—power down, secure the work, pre-inspect, and think through your moves before heat touches the board.

Once you’ve removed that bad joint cleanly, you’re free to rebuild it with something better: maybe a new component on the board, maybe a fresh set of crimp solder seal connectors, maybe a marine grade heat shrink butt connectors run for an exterior or automotive harness.

If you want the re-assembly part to go as smoothly as the desoldering, that’s where haisstronica comes in. Their solder & seal kits, solder sleeves, and sealed electrical connectors are built for real-world wiring—automotive, marine, low-voltage outdoor, or just cleaning up a messy bench project—so your next connection is cleaner, better sealed, and less likely to come back and haunt you later.