What "Total Cost of Ownership" Means for Wiring Kits and Solder Terminals

Total cost of ownership (TCO) refers to the overall cost of a product over its entire lifespan – not just the purchase price, but also all the expenses from maintenance, replacements, and any failures. In the context of wiring and electrical projects, TCO means looking beyond the upfront price of a wire connector kit or solder terminals, and considering long-term costs. A cheap kit might save a few dollars today, but if its solderless wire connectors fail or corrode, you’ll spend time and money fixing those electrical connections later. For example, one industry analysis noted that a cheap $0.50 connector failing in the field can lead to over $20 in diagnostic and labor costs to replace it. Multiply that across an entire vehicle or machine, and the supposedly “cheaper” option becomes far more expensive due to downtime and repairs. Embracing the TCO mindset encourages you to invest in quality wire connectors upfront to avoid paying for constant troubleshooting or re-splicing wires.

High-quality wiring kits and solder terminals help minimize total ownership costs by offering reliable, long-lasting performance. When connections are solid and protected, you don’t have to worry about redoing splices or hunting down intermittent issues caused by a flimsy connector. It’s a simple equation: fewer failures and less maintenance mean more savings over time. In short, paying a bit more for a quality kit – such as Haisstronica’s automotive wire connectors kit – can actually save you money in the long run, delivering peace of mind and dependable wire connections for years. Investing in a reputable brand like Haisstronica ensures your wiring projects are built to last, keeping your total costs down over the life of your vehicle or device.

Hidden Costs of Cheap Wiring Kits and Connectors

Bargain wiring kits often come with hidden costs that aren’t obvious until after you start using them. The immediate appeal of a cheap set of wire connector terminals fades when connections start failing prematurely. One hidden cost is the labor and time required to fix poor connections. Every time a crimp loosens or a joint corrodes, you’ll need to redo the work – or worse, trace an electrical fault in your vehicle. Industry experts point out that while low-quality connectors may offer short-term savings, they frequently lead to higher long-term costs as inferior parts fail and require frequent repairs. If a cheap butt splice solder connector goes bad in an exterior lighting wire or an engine harness, you might face not only replacement connector costs but also hours of labor, vehicle downtime, or even towing and garage fees. In critical applications, a faulty connector can even result in safety hazards like short circuits or electrical fires – failures that carry costs far beyond the price of a proper connector.

Another hidden cost of cheap kits is the damage they can do to surrounding components. Low-end connectors often lack proper sealing, so moisture and contaminants sneak into the wiring. Standard bargain crimp connectors leave wire ends exposed to the elements, allowing corrosion to creep under the insulation. Over time, that corrosion can travel down the copper wire (a phenomenon called capillary action), ruining the wire itself. You might end up not just replacing a connector, but also the entire wire run. Poor insulation materials are another culprit: cheap vinyl insulators can crack or let water in, undermining the wire sealing. Without a good wire sealant or heat shrink protection, connections in wet or marine environments will corrode quickly, leading to failures of waterproof connectors that weren’t truly waterproof. Ultimately, these hidden costs – extra labor, replacement parts, reduced reliability, and potential safety risks – make cheap kits a false economy. It’s far more cost-effective to use a quality, sealed connector from the start, which is why professionals and savvy DIYers choose brands like Haisstronica to avoid these pitfalls and keep their projects running smoothly.

What Makes a Quality Wiring Connector Kit (Beyond the Box Count)

More than just the number of pieces in the box, a quality wiring connector kit comes down to the craftsmanship, materials, and design of its components – ensuring reliable connections. High-grade kits stand out in a few key ways:

-

Premium Materials: Quality connectors use materials like tinned copper conductors for internal metal parts, which offer high conductivity and resist corrosion far better than bare copper. This means the connectors carry current efficiently and won’t degrade quickly. Likewise, good kits include sealed connectors with metal components that are plated (tin or nickel) to prevent oxidation. Even heavy-duty parts like 6 gauge wire connectors or battery lugs in a quality kit will be tin-plated to avoid the high resistance that develops on bare copper over time.

-

Durable Insulation and Sealing: In a quality kit, connector insulation is usually made from tough nylon or polyolefin rather than cheap plastic. Nylon-insulated terminal connectors hold up under stress and resist gasoline, oil, and UV light – they won’t crack when crimped, unlike cheaper vinyl sleeves. Many high-end kits also include dual-wall adhesive-lined heat shrink tubing built into the connectors. When heated, this tubing shrinks and the adhesive melts, acting as a wire sealer around the connection. The result is a heat shrink solder sleeve (in solder-type connectors) or a sealed crimp that creates a waterproof bond. These crimp and seal connectors ensure that the wire splice is fully insulated from water and contaminants. In automotive and marine applications, such waterproof marine electrical connectors are crucial for preventing corrosion. A properly sealed connector keeps connections dry and secure, maintaining reliable conductivity in all conditions.

-

Secure Connection Design: The best kits provide connectors that make strong mechanical and electrical bonds. For instance, heat shrink solder & seal butt connectors (which have a low-melt solder ring inside) allow you to simply insert wires and apply heat. The solder melts and fuses the wire strands while the outer tubing shrinks and seals – creating a solid soldered joint with a built-in seal. This kind of solder splice connector produces a connection as strong as the original wire, with the solder providing excellent hold. Even for traditional crimp connectors, quality versions often have features like a brazed seam on the barrel so it doesn’t split open when crimped. Some kits also include specialty pieces like solder spade connectors or ring terminals – common wire end connectors – that you can either crimp or solder, giving extra flexibility for a super secure grip. All these design elements ensure that once you make a connection, it stays tight, conducts electricity smoothly, and won’t vibrate loose even in demanding environments.

-

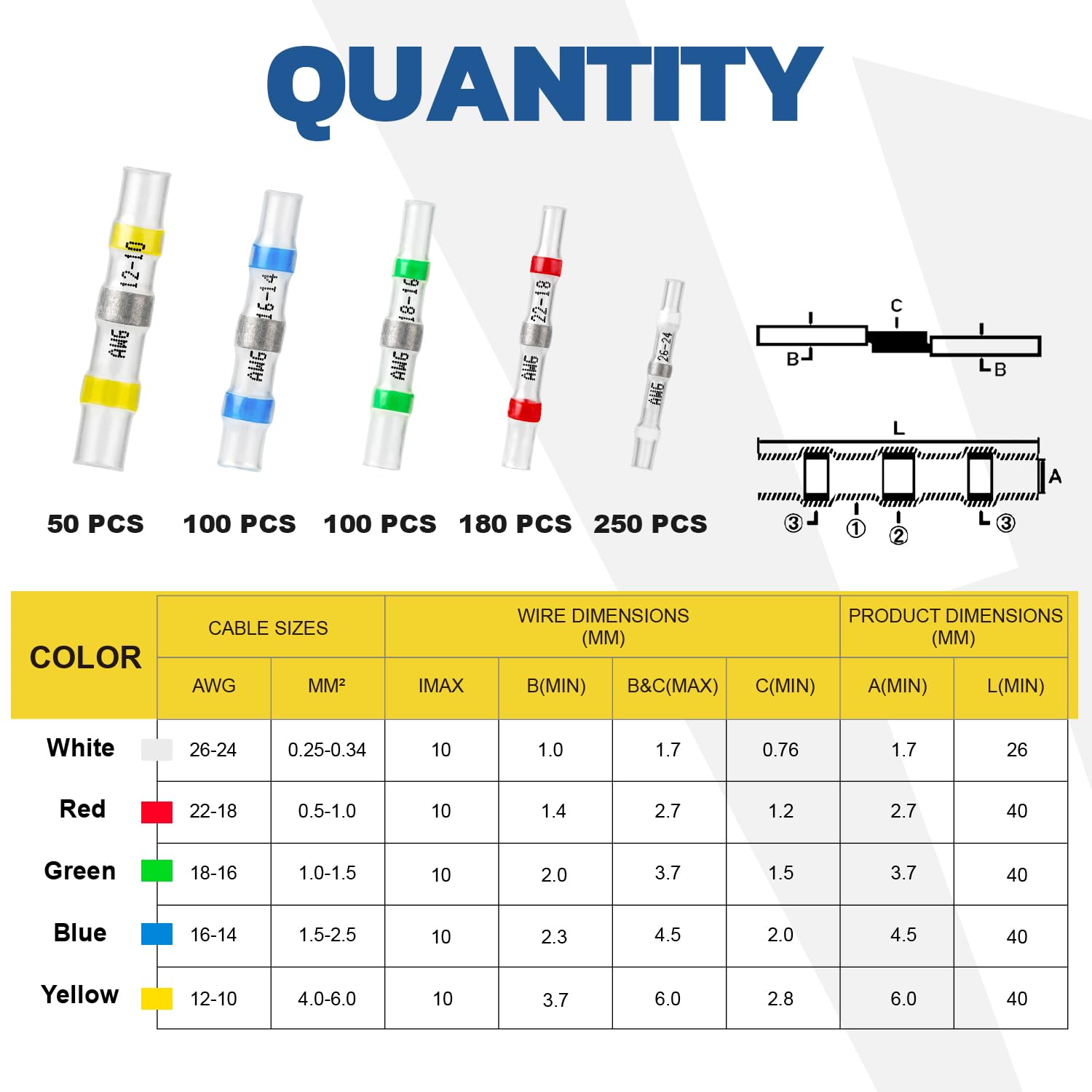

Comprehensive Selection and Compatibility: A quality kit doesn’t just give you a lot of pieces – it gives you the right pieces. This means a wide range of connector types (butt splices, ring terminals, spade terminals, wire tap connectors, etc.) and sizes to match various wire gauges. The kit should cover common automotive wire connector types as well as connectors for wires used in boats or home projects, so you’re prepared for any wiring task. For example, Haisstronica’s kit includes multiple sizes of butt splices (from small gauge up to heavy-duty solder seal butt connectors for thicker wires) and assorted terminals, all clearly organized. Having the correct connector for each job ensures compatibility and prevents the temptation to make do with an almost-fit piece (which can lead to unreliable splicing wires). Additionally, top-tier kits may adhere to industry standards (such as UL or automotive OEM specifications), indicating the components have been tested for performance and safety compliance.

In short, beyond a high piece count, a quality wiring kit is characterized by superior materials, proper sealing against the elements, robust connection integrity, and a thoughtful assortment of connector types. When you have such a kit in hand, every wire connection you make is more likely to succeed on the first try and stay solid for years. By choosing a quality kit like Haisstronica’s, you equip yourself with connectors that meet professional standards – ensuring each solder terminal or crimp you install will stand the test of time and save you from costly do-overs.

Conclusion

When considering the total cost of ownership for your electrical and automotive wiring projects, it becomes clear that quality is not an expense but an investment. Spending a little more upfront on a high-quality set of solder terminals and heat shrink solder wire connectors pays off by preventing headaches down the road. You’ll avoid the hidden costs of cheap kits – the failed connections, the water-damaged splices, the hours lost troubleshooting, and the premature replacements. Instead, you gain confidence that each connection in your car, boat, or electrical system is secure, weather-resistant, and made to last. In the long run, the best wire connectors – whether crimp terminals or solder splices – are those that you install once and forget about, because they keep working flawlessly.

Ultimately, why do quality kits save money? Because they do the job right the first time and protect your entire electrical system from the chain reaction of problems that a single weak connector can create. From safeguarding against corrosion with proper wire sealing, to maintaining low resistance and high conductivity with tinned copper contacts, a premium kit addresses the very issues that cause cheap components to fail. The result is fewer repairs, less downtime, and a safer, more reliable network of wiring. That’s real value for any installer or DIY enthusiast. So, next time you’re choosing an electrical connectors kit, think in terms of total cost of ownership. Investing in a reputable brand like Haisstronica means choosing connectors that will perform reliably for the long haul – minimizing future costs and giving you the confidence to tackle any wiring project while saving money in the end.