Carrello

Il tuo carrello è vuoto

High-performance soldering butt connectors with pre-measured solder sticks deliver fast, weatherproof joints in one heat step; these marine-grade butt connectors with solder feature gauge markings, impact-resistant heat shrink and dual adhesive rings to ensure long-lasting, corrosion-resistant connections even in harsh, wet environments.

Secure Payment via:

Features:

Shrinkable Seal

Electrical wire sealant flows, forming flexible, waterproof insulation.

Solder Wire Connection

Molten solder for wire connections creates durable, sealed joint.

Solder Seal Connectors

Best solder seal wire connectors, also suits solderless butt connectors.

Quick Secure Connections

Perfect for outdoor projects, it keeps your connections safe from moisture and corrosion.

Guaranteed Weatherproof

Its innovative design ensures a secure bond every time, making your projects smooth and efficient.

Easy To Use & Saves Time

Save time and effort with connectors that simplify your tasks without compromising quality.

Enhanced Safety

Reduce burn & hazard risks to ensure a safer working environment, while being 100% safe for electronics.

Fits All Projects

From automotive repairs to home improvements, it’s the go-to solution for any wiring challenge.

Lasting Reliability

With high-quality materials and construction, it delivers reliable connections that stand the test of time.

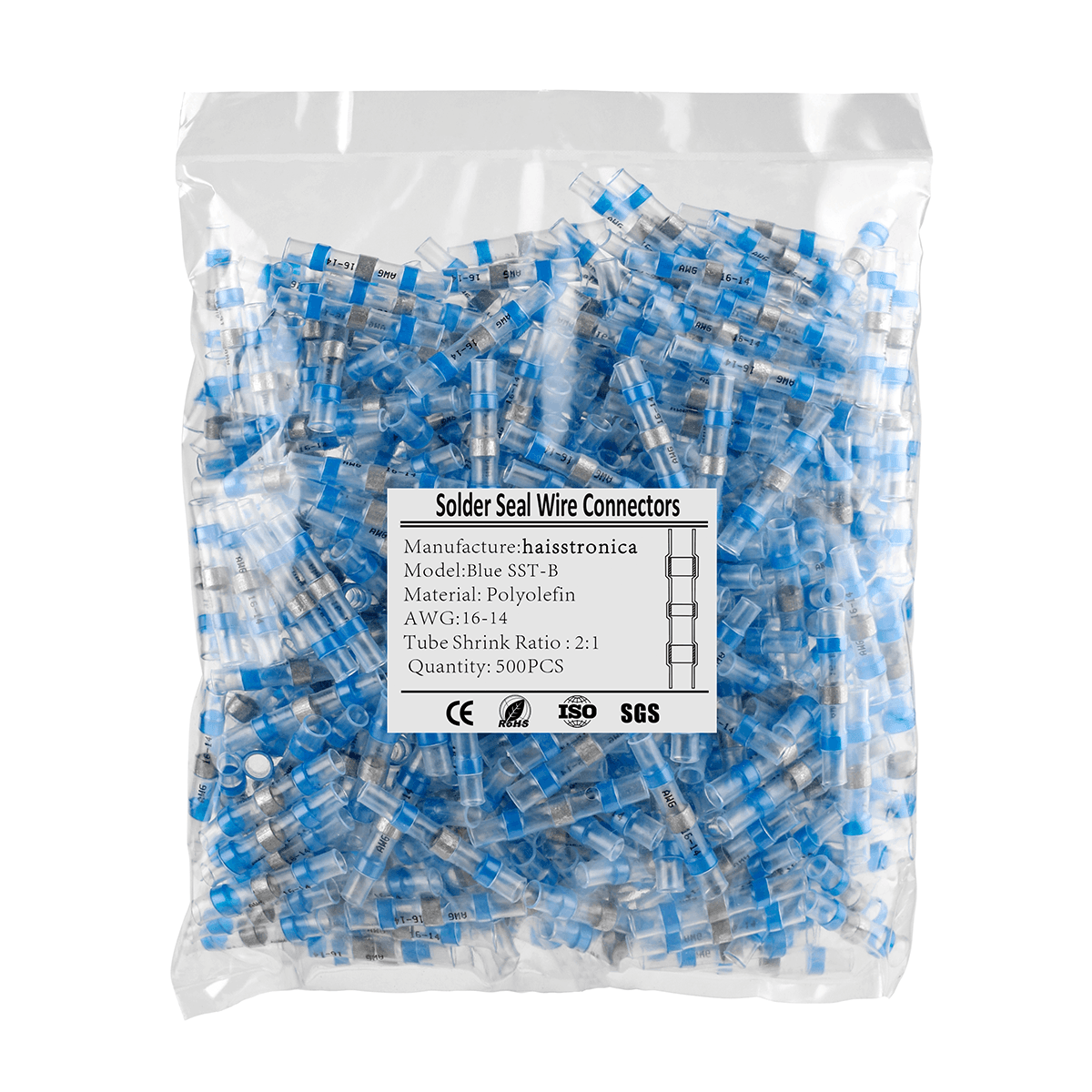

Haisstronica offers a full line of waterproof wire connectors—our best-selling solder seal wire connectors and solder and seal wire connectors—so you can match the right piece to your job. A solder seal wire connector (also called a heat shrink solder connector, solder sleeve connector, or butt connector with solder) is used to splice two conductors and seal the joint in one step. Each piece combines a clear heat-shrink tube, a low-temperature solder ring, and dual hot-melt adhesive bands to deliver a tight, durable splice for automotive wire connectors, marine projects, and home wiring.

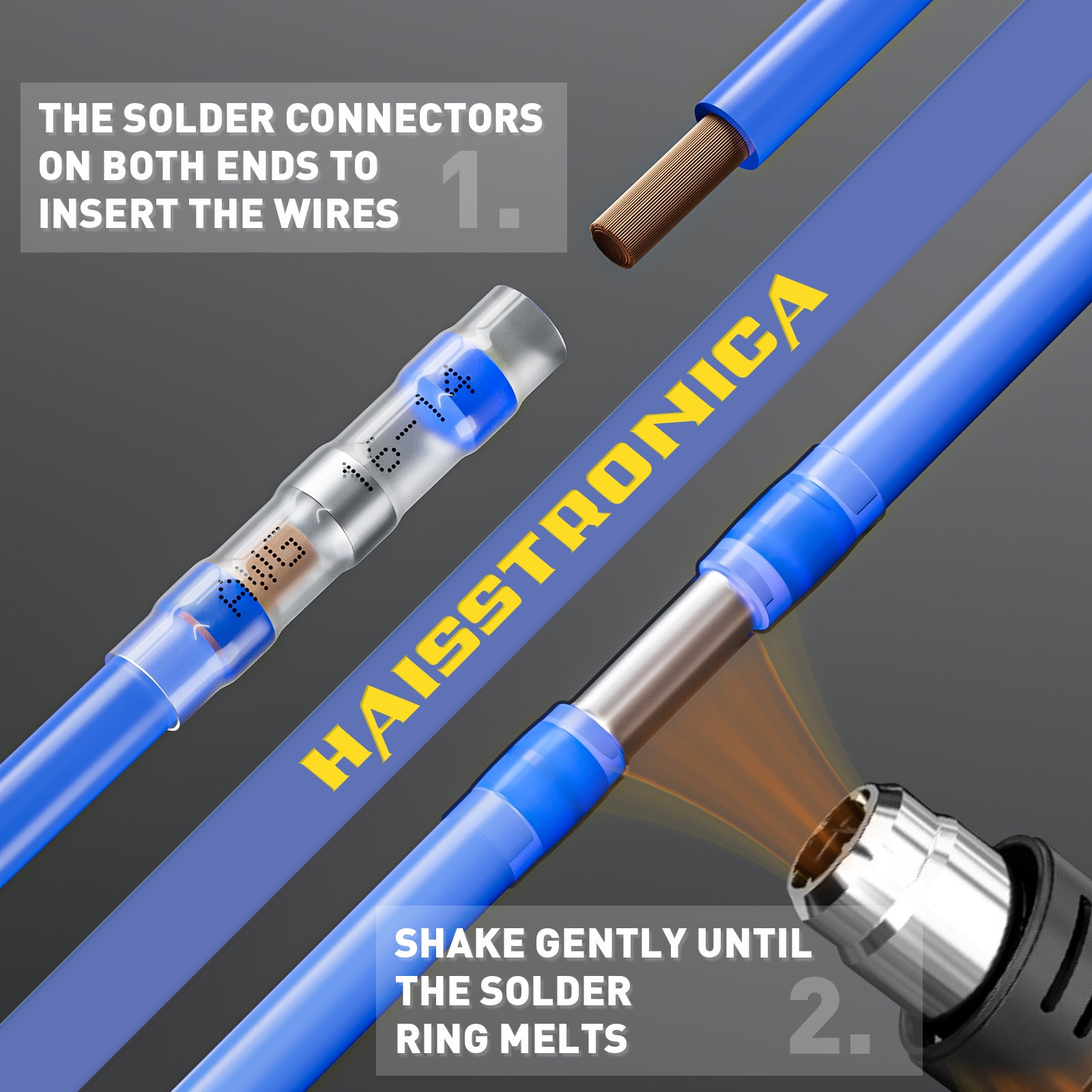

How it’s built and how it works: the clear EVA/polyolefin tubing lets you see soldering penetration as the alloy melts and flows; the hot-melt adhesive cools in seconds and locks out moisture; and the integrated solder sleeves create an electrically solid, long-lasting soldered connector. Slide the sleeve over stripped conductors with proper overlap, center the solder ring, then apply even heat—this is true solder and heat shrink in a single motion, no crimp required. When finished, the joint behaves like a one-piece, sealed solder connector.

For maximum strength and sealing, choose the connector by the conductor gauge—not by overall jacket thickness or extra wrap. Haisstronica prints the wire gauges directly on the tubing for quick pick-and-place selection, so you always match the right solder butt connector to the job. Clean copper strands, insert to full depth, and heat until the solder heat shrink flows and the adhesive forms continuous fillets at both ends. Selecting by true AWG and heating evenly prevents weak joints often seen with mis-sized or under-heated solder wiring connectors.

Count on Haisstronica for quality, sturdy solder connectors that secure loose ends and keep systems running. Our hot-melt system delivers the right amount of adhesive that cools, hardens, and reaches bond strength within seconds—ideal sealed connectors for field service. If you need reliable wire solder connectors that stand up to vibration, water splash, and road grime, our kits are ready. For product details and sizing help, browse our catalog of wire connectors with solder. Questions about waterproof solder wire connectors for your application? Contact us—our team is here to help.

Want deeper know-how? Read our step-by-step guides on installing heat shrink solder connectors and choosing the correct size of solder seal connector for different wire bundles. You’ll learn best practices for staggering splices, managing strain, and routing solder wire connections in tight spots—techniques that make shop or roadside repairs as fast as bench work.

There are three common splice styles in our range: 1) straight solder butt connectors for end-to-end joins; 2) ring and spade solder terminals for panel terminations; and 3) inline solder splice connectors for multi-segment repairs. Your application drives the choice. For critical or wet locations, always use crimp and seal connectors or our solder & seal sleeves that combine electrical continuity with an adhesive-lined barrier. Avoid plain solderless connectors where a watertight joint is required.

What’s inside matters. Our tubing is abrasion-resistant EVA/polyolefin for long-term reliability; the transparent body confirms full wire connector solder flow; and the adhesive bands act as a true wire sealer. Compared with simple heat-shrink alone, the integrated alloy creates a robust solder wire splice that won’t wick moisture or loosen under vibration—exactly what you want in automotive wire connectors kit repairs, boat wiring, and outdoor installs.

To achieve the designed performance, use the minimum connector count for the route and heat each piece to full activation—the solder must liquefy and the ends must seal. Space splices to avoid concentrated bending, and let the joint cool before loading. Following these steps allows the assembly to reach its intended efficiency, the same way torque is essential for mechanical hardware.

Finish options in our line address real-world conditions. Choose color-coded sizes for quick identification, or reach for assorted kits when servicing mixed harnesses. Whether you’re shopping solder stick connectors, compact quick solder connectors, or full solder wire connector kit assortments, you’ll find the right match for repair benches, trail bags, and service trucks.

Haisstronica stands behind every connector. If you’re not satisfied, reach out—our quality commitment means we’ll make it right. When your project demands best waterproof solder wire connectors that combine electrical integrity with a dependable shrinkable seal, choose Haisstronica solder seal wire connectors for results that last.