電線の圧着は電気工事の基本スキルですが、間違ったやり方をすると接続が緩んだり、過熱したり、さらには火災につながる可能性があります。DIY愛好家でもプロの電気技師でも、このガイドで圧着のコツを学べます。 ワイヤーを安全かつ効果的に圧着する方法と、高額な費用がかかるミスを避けるためのプロのヒント。

適切な圧着が重要な理由

-

安全性: 圧着が不十分な接続は過熱の原因となり、機器を損傷したり、火災を引き起こしたりする可能性があります。

-

耐久性: 適切な圧着により、振動、湿気、温度変化に耐えます。

-

コンプライアンス: 認定設置に関する NEC (National Electrical Code) および UL 規格に準拠しています。

必要なツール

-

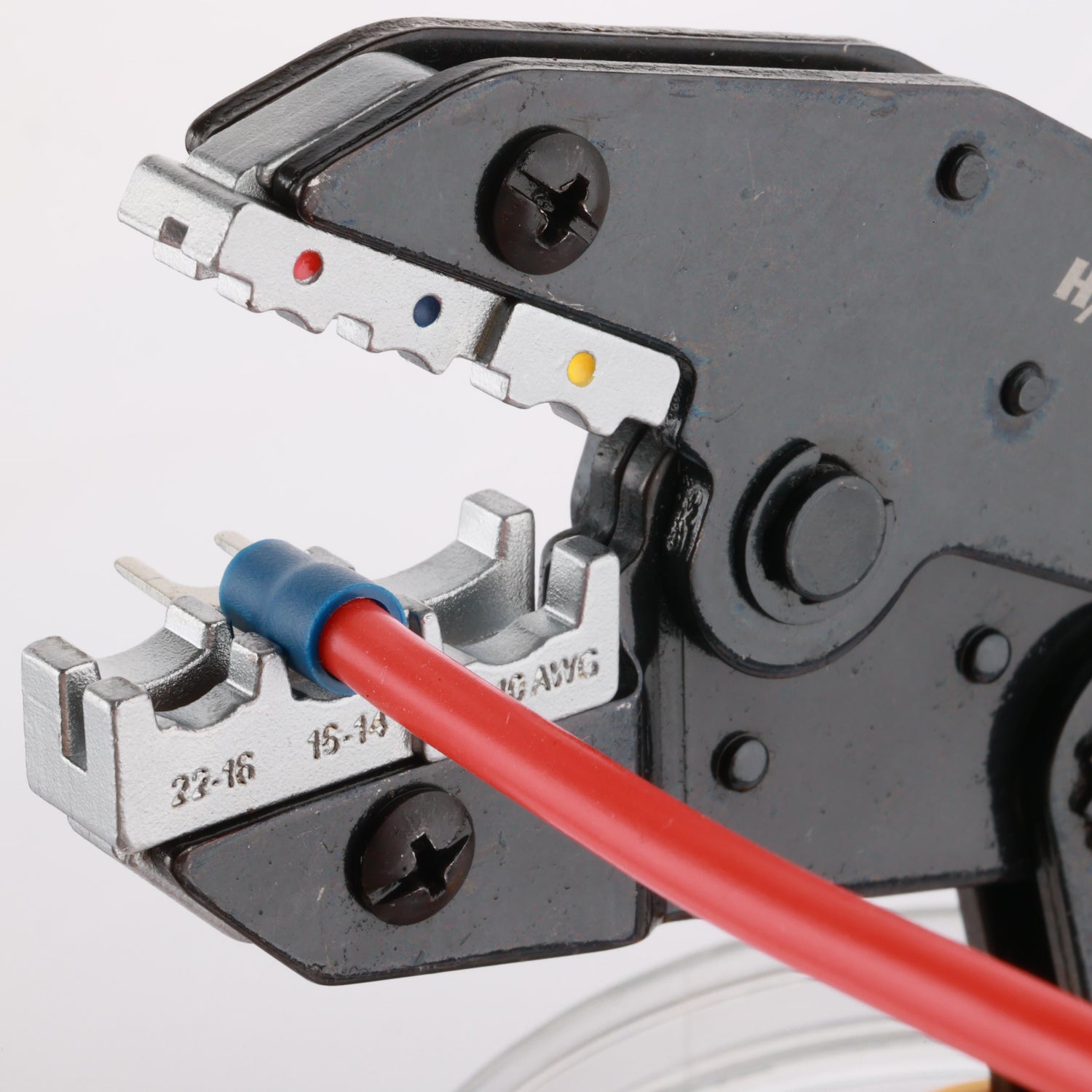

ワイヤー圧着工具 (例えば、 ハイストロニカ ラチェット クリンパ

-

一貫した圧力を得るにはラチェットモデルを選択してください。

-

-

熱収縮チューブ (オプション、防水用)

ステップ1:電線の被覆を剥ぐ

-

目標: 1/8 インチから 1/4 インチの裸線を露出します。

-

プロのヒント: ストリッパーのゲージをワイヤのサイズ (例: 12 AWG) に合わせてください。

❌ 避けるべきこと: 撚り線に傷をつけること。導電性が弱まります。

ステップ2:適切な端末を選択する

-

絶縁 vs. 非絶縁: 家庭用/自動車用アプリケーションには絶縁端子を使用します。

-

サイズの一致: 端子バレルはワイヤの直径に適合する必要があります (パッケージのラベルを確認してください)。

一般的なタイプ:

ステップ3:ワイヤーを挿入する

-

被覆を剥がした電線を端子バレルに押し込み、完全に固定します。

-

チェック: バレルの外側に裸線が見えてはいけません。

ステップ4:端子を圧着する

-

端子を圧着工具の適切なダイス(ワイヤゲージのマーク付き)に配置します。

-

ツールが自動的に解放されるまでしっかりと握ります (ラチェット モデル)。

-

検査:

-

バレルは均一に圧縮される必要があります。

-

引っ張りテスト – ワイヤーが抜けてはいけません。

-

💡プロのヒント:高負荷のアプリケーションの場合は、 粘着剤付き熱収縮チューブ クリンプの上。

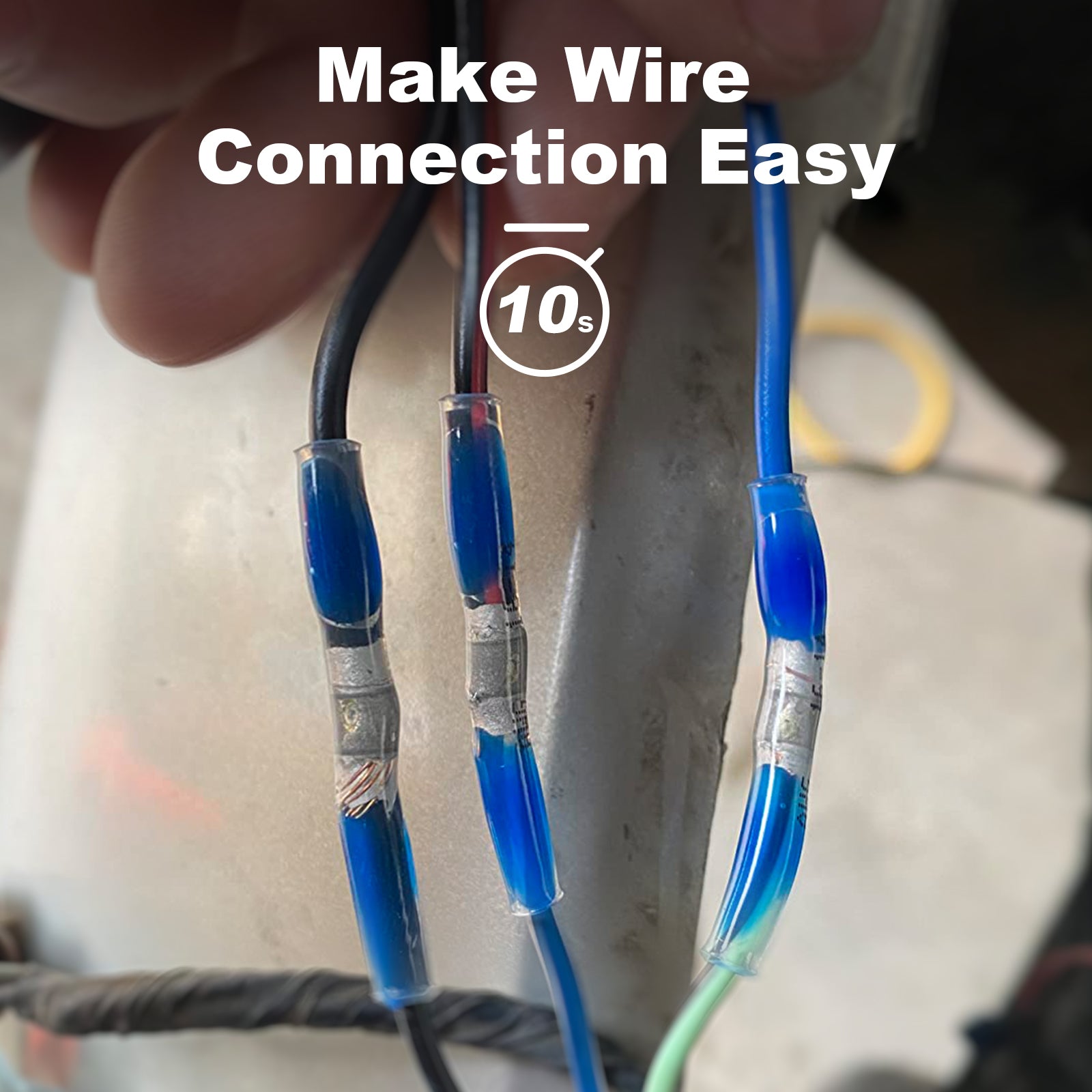

ステップ5:シールと保護(オプション)

-

熱収縮チューブを圧着部に差し込みます。

-

ヒートガンを使用して収縮させ、防水シールを作ります。

最も一般的な圧着ミス5つ

-

端末サイズが間違っています → 接続が緩んでいます。

-

圧着不足/圧着過剰 → 接着力が弱い、または絶縁体が潰れている。

-

撚線と単線を無視する → 撚線にはフェルールを使用します。

-

綱引きテストをスキップする → 負荷がかかると故障するリスクがあります。

-

圧着ペンチの代わりにペンチを使う → 圧力が一定でない。

高度なテクニック

-

ダブル圧着: 激しい振動(例: 自動車)に対応するために、ワイヤと絶縁体の両方を圧着します。

-

耐候性:圧着と 船舶用熱収縮チューブ。

よくある質問

Q: 圧着端子は再利用できますか?

A: いいえ。圧着すると金属が変形します。端子は必ず交換してください。

Q: ソーラーパネルの配線に最適な圧着工具は何ですか?

A: 使用 Haisstronica の CT-200 シリーズのような、 AWG 10-22 ダイを備えたラチェット圧着工具。

Q: 圧着工具を使わずに圧着するにはどうすればいいですか?

A: やめてください。即席の工具(ペンチ、ハンマー)を使用すると、危険な接続が生まれます。

結論

ワイヤー圧着をマスターすれば、安全で信頼性の高い電気システムを構築できます。プロ並みの結果を得るには、スキルと適切な工具を組み合わせてください。

✅ Haisstronicaのショップ 圧着キット – ラチェット式圧着工具、端子が付属します。

1 コメント

pradeep perelly

Terrific article. I appreciated the structure and the various pcs of information Thanks for sharing this useful information

https://www.couponcode2save.com/

Terrific article. I appreciated the structure and the various pcs of information Thanks for sharing this useful information

https://www.couponcode2save.com/