Maintaining a wire crimper might not be the most glamorous part of electrical work, but it’s absolutely vital. Think of your crimping tool (often called a wire crimp tool, crimping pliers, or ratchet crimping tool) as an investment – taking care of it ensures it performs properly and lasts for years. In this workshop-style guide, we’ll cover everything from why maintenance matters to the exact steps of cleaning and oiling your crimper. By the end, you’ll be able to maintain your crimping tool like a pro, and keep those wire connections tight and safe (all while protecting your investment in a quality tool). Remember: a little TLC for your tool goes a long way – and if you’re using a high-quality crimper like Haisstronica’s, proper maintenance can help it deliver professional results for a decade or more!

Why Crimping Tool Maintenance Matters

Just like a car or a kitchen appliance, a crimping tool needs regular care. Over time, dust, dirt, and tiny metal shavings from wires and connectors build up in your tool’s moving parts. If ignored, this gunk can cause your crimper to operate less smoothly, wear out faster, or even start producing poor electrical connections. In fact, one of the biggest factors in crimp quality is a tool that’s in good condition. Regular crimping tool maintenance (cleaning and lubricating) preserves the tool’s function and extends its lifespan. It also maintains the quality of your crimps – a dirty or stiff tool might not fully crimp connectors, leading to loose or unreliable connections, which no electrician or DIYer wants.

Why does maintenance make such a difference? First, cleaning removes debris that can prevent the crimp jaws from closing completely. Even small bits of copper or insulation debris in the die area can affect crimp performance. Second, oiling the moving joints reduces friction and prevents rust. A well-oiled pivot and hinge mean your ratcheting crimper closes effortlessly and applies consistent pressure on every squeeze. Neglecting lubrication, on the other hand, can make the tool hard to operate and increase wear on critical parts. Finally, taking care of your crimp tool saves you money. Proper maintenance improves the longevity of your tool, reducing the need to buy new tools frequently. In short, a little maintenance ensures your crimper wire tool always performs at its best, which keeps your wiring projects safe and trouble-free. Spend a few minutes maintaining your tool, and you’ll be rewarded with years of reliable service – Haisstronica’s crimpers, for example, are built to last and will serve you even longer when cared for properly!

What You’ll Need to Clean Your Wire Crimping Tool

Before we dive into the process, gather the supplies and tools you’ll need for cleaning and oiling your crimp tool. Fortunately, maintaining a wire crimper tool doesn’t require any fancy equipment – you probably have these items on hand:

-

Soft Cloth or Rag: Use a lint-free cloth (an old cotton T-shirt or microfiber rag works great) for wiping down your tool.

-

Soft-Bristle Brush: A small brush helps dislodge debris. An old toothbrush or a small wire crimping brush is ideal. (Avoid wire brushes on polished areas; stick to soft bristles to prevent scratches.)

-

Lightweight Machine Oil: A light oil is key for lubrication. Common choices are 3-in-1 oil or a light machine oil in the SAE 20 weight range. These oils are inexpensive and perfect for hand tools. (Avoid heavy grease or thick oils, which can trap dirt.)

-

Isopropyl Alcohol or Mild Solvent (Optional): Useful for cutting through old grease or sticky grime. A few drops on a cloth can help clean tough dirt.

-

Penetrating Oil (Optional): If your crimping tool has a spot of rust, a bit of penetrating oil (like WD-40) can loosen it. (Remember, WD-40 is a cleaner and water-displacer, not a long-term lubricant – you’ll still oil the tool after.)

-

Fine Steel Wool or Sandpaper (Optional): #0000 steel wool can gently remove light rust from steel surfaces if needed. Use carefully and sparingly.

-

Safety Gear (Optional): If you have sensitive skin or are working with solvents, gloves are a good idea. Safety glasses protect your eyes if you’re brushing off debris.

Having these items ready will make the maintenance process quick and efficient. There’s no need for any specialized “crimping tool maintenance kit” – simple household supplies work fine. The key is using a proper lubricant: a drop of quality oil will keep any ratchet crimping tool running smoothly without attracting too much grime. Pro Tip: Keep your cleaning supplies in the same toolbox as your connectors and crimping wire tool. That way, after you finish crimping a batch of wire connectors, you can easily give your tool a quick wipe and oil before putting it away. By using good supplies – and high-quality tools like Haisstronica’s – you’ll find maintenance to be straightforward and worth the minimal effort!

Know the Anatomy of Your Crimping Tool (Cleaning & Lubrication Points)

To maintain your crimping tool effectively, it helps to understand its key parts and where to focus your attention. A typical wire crimping tool (especially a ratcheting one) has several important components:

-

Jaws/Dies: These are the interchangeable or built-in pieces that actually crimp the connector onto the wire. They often have calibrated profiles for different connector sizes. Cleaning focus: Keep the jaws (crimping die surfaces) free of debris. After lots of crimps, you might see small bits of cut wire or insulation in the die pockets – brush those out. Never apply oil or grease to the crimping surfaces; any oil on the dies can transfer to your connectors and wires, causing poor electrical contact. You want the dies clean and dry for a solid crimp every time.

-

Fulcrum/Pivot Point: This is the hinge where the tool’s handles join. It’s essentially the heart of the crimper – when you squeeze the handles, the pivot is what allows the jaws to come together with force. In tool anatomy terms, the fulcrum is where the jaws and handles connect and it generates the force for crimping. Cleaning focus: Wipe away any grime around the pivot. Lubrication focus: Apply a drop or two of light oil here; it will seep into the joint and ensure smooth movement. Work the handles open and closed after oiling to distribute it. This prevents that squeaky or stiff feeling and reduces wear on the hinge.

-

Ratcheting Mechanism (if applicable): Many professional ratcheting crimpers have an internal ratchet that controls the cycling of the tool (it won’t release until a full crimp is made, ensuring consistency). You might notice a dial or screw for adjusting tension as well. Cleaning focus: Use the brush to clear any particles around the ratchet teeth. Lubrication focus: A tiny drop of oil on the moving ratchet parts or the tension screw can keep it engaging smoothly. Again, don’t over-oil – excess oil in the ratchet can attract dust.

-

Handles and Spring: Your crimper’s handles are usually steel with comfortable grips. Some tools have a spring that automatically opens the jaws when you release. Cleaning focus: Wipe down the handles, and make sure to clean around the base where the handles pivot. If there’s a return spring, brush off any dirt on it. Lubrication focus: A small drop of oil on the spring or where it attaches can prevent rust and squeaks. For the handles themselves, you usually don’t oil them (you don’t want slippery grips!), but you might put a thin coat on any exposed metal surfaces for rust prevention – then wipe it off so it’s just a micro-film.

By knowing your tool’s anatomy, you can divide your maintenance into “cleaning zones” and “lubrication points.” The crimping dies = cleaning zone (no oil). The pivot and moving joints = lubrication points (a little oil goes a long way). If you’re ever unsure, check if your tool came with a manual or instructions – manufacturers often specify spots to oil. Most electrical crimping tools are very straightforward, and the same maintenance principles apply whether you have a small terminal crimper, a heavy-duty cable crimper, or a multi-purpose wire connector crimping tool. Understanding your crimper’s design will make you more confident in maintaining it. Plus, when you use a well-designed tool – like Haisstronica’s ratcheting wire crimper – you’ll notice it’s built for easy upkeep (with robust hinges and quality steel that stands up to cleaning). Knowing your tool means you’ll take better care of it, ensuring it serves you well on every wiring project!

Step-by-Step: Clean First, Then Oil (Standard Process)

Now let’s get into the step-by-step process of cleaning and oiling your crimping tool. We’ll assume you’re dealing with a common manual ratchet crimping tool (the steps are similar for non-ratchet crimpers too). Set aside a little workspace – a bench or table with good lighting – and let’s begin. Remember: always clean the tool first, then oil it. Cleaning removes grit that you don’t want to trap in place with oil. Here’s the standard maintenance routine:

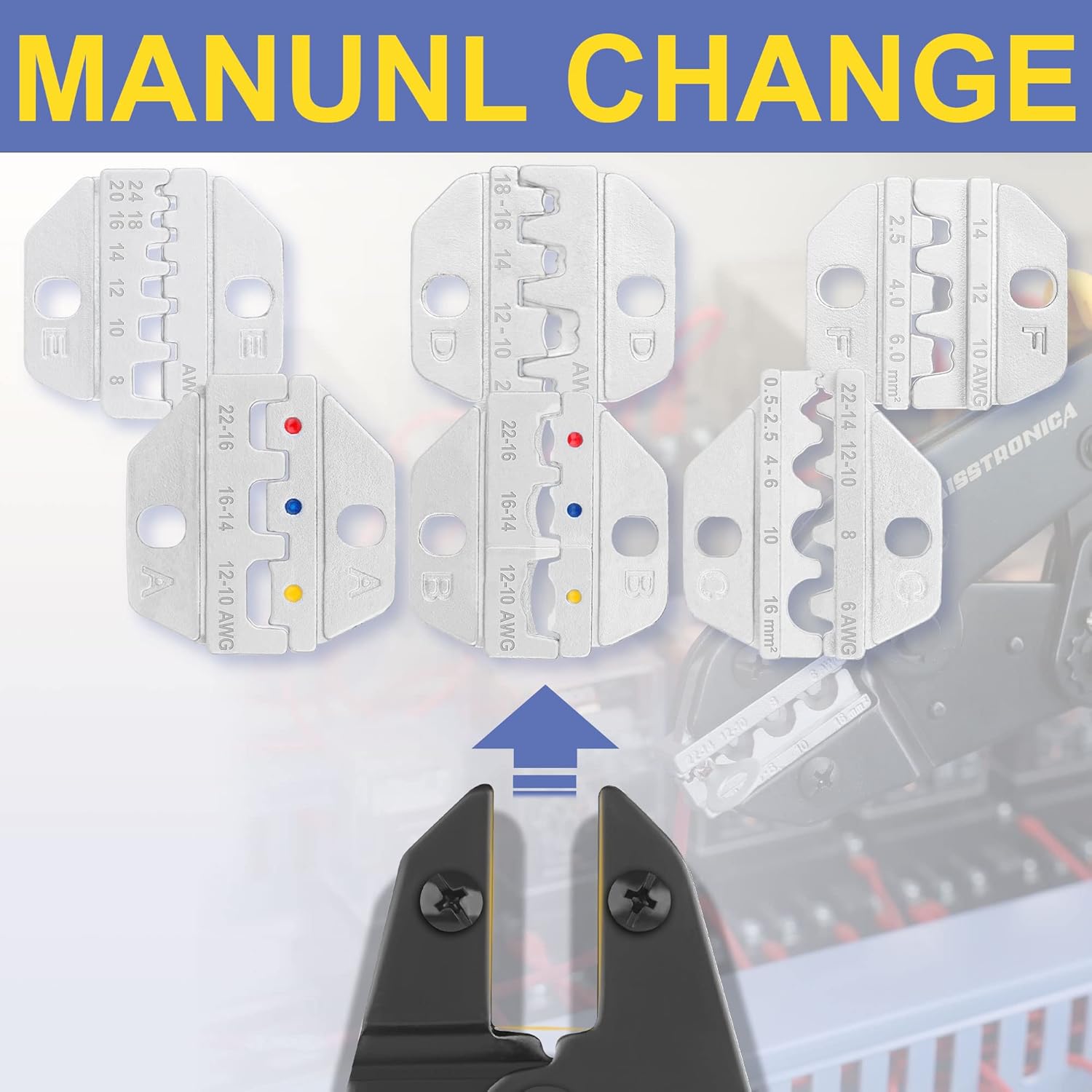

1. Prepare & Inspect: Start with the tool in hand and make sure there’s no connector or wire in it. If your crimper has interchangeable dies or parts, you can remove them now for separate cleaning (follow the tool’s manual if applicable). Take a quick look at the tool’s condition: note any rust spots, stuck-on grime, or damage. This inspection helps you target what needs attention (e.g., a rusty hinge or gummed-up jaw). Using a headlamp or magnifier can help spot tiny debris in the crimping jaws. If you see any cracks or serious wear (like bent jaws or a loose pivot pin), consider repairing or replacing the tool – maintenance can’t fix a broken tool beyond a certain point, and a damaged crimper can compromise your connections.

2. Wipe Off Dirt and Debris: Using your soft cloth, wipe down the entire crimping tool. Pay special attention to the jaws (dies), the pivot area, and any crevices. This will remove loose dust, metal shavings from wire cutting, and general dirt. Next, take your soft-bristle brush and gently scrub around the crimping die grooves to dislodge stubborn particles. Do NOT use compressed air to blow out the tool; blasting air can actually force debris deeper into the mechanism or into places it shouldn’t go. Also avoid using abrasive materials or sandpaper on precision parts – you don’t want to scratch the die surfaces or remove protective coatings. If there’s any greasy residue or sticky grime, dampen a corner of your cloth with a bit of isopropyl alcohol or WD-40 and wipe those areas until clean. Take your time to ensure all visible dirt is gone. A clean crimping tool not only operates better, but also gives you a chance to closely examine the condition of the dies and moving parts.

3. Remove Rust (If Present): If you spotted any light rust on the tool (commonly this might happen on the handles, hinge, or other steel parts if the protective finish has worn off), address it before lubricating. Take a small piece of fine steel wool (#0000 grade is excellent for this) or a rust-removing product, and gently rub the rusty area until the rust is cleared. You don’t need to go overboard – the goal is to remove loose rust flakes and restore a smooth surface. For any tight spots, a drop of penetrating oil can help loosen rust. Afterward, wipe the area thoroughly dry with your cloth. The tool should be completely dry and free of solvent before you apply fresh oil. This rust removal step ensures that you’re not just oiling over rust (which would seal in moisture and possibly make corrosion worse). Once done, the metal should be clean, smooth, and ready to be protected with oil.

4. Lubricate the Moving Parts: Now that the crimper is clean, it’s time to oil the tool’s moving joints. Take your lightweight machine oil and apply one or two drops at the pivot/hinge – this is the primary point that needs lubrication. If your tool has a ratchet mechanism, also apply a tiny drop to the ratchet teeth or any visible moving linkage. You might also put a drop on the spring (if there is one) or where the handles contact the spring. Important: Avoid getting oil on the crimping die surfaces or any area that will directly touch the wire connectors. Oil or grease on the dies can transfer onto electrical terminals, and that residual oil can interfere with the electrical connection or attract dirt. In maintenance best practices, experts warn never to lubricate the actual crimping surfaces for these reasons. So stick to oiling the joints and hinge points only – essentially, oil where metal rubs against metal in the tool’s action. After applying the drops, open and close the crimping tool several times (cycle it through a full crimp if it’s a ratcheting tool) to work the oil in. You’ll likely feel the action become smoother. Finally, take a clean part of your cloth and wipe off any excess oil from the tool. The goal is a thin film in the joints, not dripping oil. A light coating is sufficient to reduce friction and prevent oxidation. Your electrical crimping tool should now move freely without stickiness or squeaks.

5. Test the Tool’s Function: Maintenance is done, but before you put the tool away, do a quick function check. Open and close the handles a few times and ensure everything moves properly. If you have a ratchet crimper, squeeze until the ratchet engages and releases at the proper point – it should latch and unlatch smoothly. The tool should feel almost like new: no grinding sensations, no hitching. If you want, you can also crimp a scrap piece of wire with a spare connector (or just crimp an empty connector) to see that the dies align and you’re getting a clean crimp. This also helps confirm that no oil has snuck onto the crimping area – the connector should come out crimped tight and dry. If it slips or you see oil, pause and degrease the jaws with alcohol, then dry and test again. Generally, if you followed the steps, you’ll have no issues. A smooth test run now means your maintenance was successful. You’ll notice how much nicer a freshly cleaned and oiled wire connector crimper feels in hand!

6. Proper Storage: The last step is storing your crimping tool the right way until its next use. Even the best cleaning won’t last if the tool is tossed into a damp corner of the garage. Store the tool in a clean, dry place – for example, in your toolbox or a drawer that doesn’t get humid. If your crimper has a locking latch to keep the handles closed, latch it; storing the tool closed can prevent the sharp dies from banging into other tools and keeps dust out of the jaw area. Consider adding a silica gel packet in your toolbox if you’re in a humid climate, to avoid rust. Storing your crimping tool properly helps **minimize rust or corrosion caused by moisture exposure】. Also, don’t leave the tool where it can collect dust easily; a quick wrap in a cloth or placing it in a ziplock bag can be useful for long periods of storage. With clean, oiled joints and safe storage, your crimping tool is now set to deliver reliable performance the next time you need it.

Following these steps will keep your trusted crimping tool for electrical connectors in peak condition. This whole process only takes a few minutes but yields a big payoff: your tool will last longer, and you’ll crimp with confidence knowing the tool won’t let you down mid-job. It’s a simple preventive routine that professional electricians and savvy DIYers alike swear by. In fact, some experts recommend giving your crimper a quick wipe and oil after every heavy use or at least every few hundred crimps – that might sound like a lot, but the principle is to clean and lube before any serious issues arise. The bottom line is, regular cleaning and oiling prevents problems rather than fixing them later. By taking care of your crimper, you’re protecting your investment. High-quality tools such as Haisstronica’s professional ratchet crimpers are designed to withstand years of use, and with proper maintenance, they’ll continue to provide clean, solid crimps for a very long time. Treat your tool well, and it will return the favor with top-notch performance on every project!

Conclusion: Keep Crimping Like a Pro

Maintaining your crimping tool isn’t complicated, but it’s the key to a long lifespan and reliable performance. Just a little bit of routine cleaning and a drop of oil can keep your electricians’ crimping tool working like new, ensuring every connection you crimp is secure and electrically sound. Remember, a well-cared-for wire crimper not only lasts longer but also makes your work easier – you won’t have to fight a rusty hinge or wonder if the tool is the reason for a bad connection. In fact, these simple maintenance steps can keep a good crimping tool working for 10 years or more without issues. On the flip side, neglecting your tool might shorten its life and lead to problems like incomplete crimps or even tool failure. The choice is easy: a few minutes of upkeep for countless hours of smooth crimping.

We hope this guide has made the how and why of crimping tool maintenance clear. It’s all about keeping your tool clean, lubricated, and protected so that it can do its job flawlessly. Now you can confidently clean and oil your crimping tool like a pro! Make it a habit – perhaps at the end of a big wiring project, or a set schedule like every month – to give your crimper a quick once-over. Your future self (and your wiring work) will thank you.

At Haisstronica, we’re passionate about reliable electrical connections. We design our professional crimping tools and heat shrink connectors with durability in mind, but even the best tools perform their best with proper care. So take pride in maintaining your gear. If you’re looking to upgrade or need quality accessories, be sure to check out Haisstronica’s range of wire crimpers, connectors, and more – we’ve got everything you need to crimp with confidence. Happy crimping!

Sources: