Let’s address the big question first: Are solder on wire connectors suitable for saltwater applications? The honest answer is, “sometimes—when used in the right place, with the right technique.” Marine electrical systems are governed by safety and reliability expectations that exceed typical automotive duty because failures can be mission-critical offshore. Standards bodies (ABYC, USCG) emphasize mechanically secure terminations with proper strain relief and environmental sealing. That’s why adhesive-lined crimp and solder connectors (or more commonly, adhesive-lined crimp butt splices) are often preferred for high-vibration or high-current circuits.

Where do heat-shrink solder connectors fit? They excel for low-to-moderate current branch circuits and sensor/lighting harnesses in protected runs, junction boxes, and dry cabin spaces—especially when you need fast, clean, repeatable sealing without a dedicated crimp frame on board. In those scenarios, high-quality sleeves with clear tubing, a solder heat shrink ring that fully wets both conductors, and dual hot-melt adhesive bands can deliver an electrically sound splice plus a water-resistant seal.

There are important caveats:

-

Never use them as a substitute for proper terminations on large-gauge, high-current conductors (batteries, starters, windlass feeds, inverter cables). For those, use listed lugs, correct crimp tooling, and adhesive heat-shrink.

-

Avoid continuous flex zones. A soldered section is inherently rigid; in a hinge loop or engine-mounted harness, that hard spot can concentrate bending stress.

-

Mind ambient temperature. Prolonged exposure near 105–125 °C components (engine compartment hotspots) can weaken the tube or adhesive.

If you follow those boundaries, solder on wire connectors are a practical option aboard—especially for service and field repair kits—provided you pair them with correct sizing, strain relief (loom/clamps), and good routing to prevent water pooling.

Pro tip: If you don’t know which size you’ll face, carry a mixed AWG kit like the Haisstronica 180-piece set. It covers 26–10 AWG with the common color codes you already use ashore.

Materials That Matter — solder on wire connectors

Saltwater punishes the wrong materials. The difference between a connection that’s still bright and one that’s green and gritty after a season often comes down to metallurgy, adhesives, and tubing chemistry. Here’s what to demand from marine-use soldering connectors and the wires you’re joining.

1) Tinned copper conductors (wire side)

Marine-grade wire uses finely stranded, tinned copper. The tin layer significantly slows galvanic corrosion and creep in humid, salty atmospheres. If you’re splicing to non-tinned automotive primary wire, expect a corrosion head start—mitigate it with perfect sealing and dielectric protection. When possible, stick to marine tinned wire for both sides of the splice.

2) Fluxed, low-melt solder ring (connector core)

The solder ring in quality solder sleeves should melt at a temperature you can reach with a compact heat gun (not an open flame), contain an internal flux to break oxides, and turn shiny when fully flowed. Granular or partially melted rings create high resistance and intermittent faults. Inspect through the clear tube: no voids, no “cold” matte frosting, and visible wetting into both strand bundles.

3) Adhesive-lined, marine-grade heat-shrink (outer tube)

Look for heat shrink solder connectors with dual hot-melt adhesive bands—one on each side of the solder ring—so the sealant wets out onto the insulation jackets as the tube shrinks. In saltwater use, this adhesive barrier is what keeps capillary water from wicking down the strands. A 3:1 shrink ratio covers most primary insulation; 4:1 is helpful when one side has thin-wall insulation (e.g., sensor leads) so you still get a solid circumference seal.

4) Clear, abrasion-resistant tubing

Clear tubes enable visual QA: you can verify conductor overlap, solder flow, and adhesive beading. A thicker wall and tighter recovered diameter resist scuffing from loom edges and clamp feet. UV-stable tubing is beneficial for exposed lockers or lazarettes with daylight leaks.

5) Chemically compatible adhesives

Hot-melt wire sealant must bond well to PVC, cross-linked polyethylene, and common jacket materials. Incompatibility shows up as edge lift or a gummy, non-uniform bead after cool-down. With properly matched materials, you should see a continuous meniscus at both ends of the sleeve.

6) Corrosion inhibitors and post-seal protection

Although the sleeve seals the splice, finishing the harness with drip-loops, solder shrink sleeves or extra adhesive-lined heat-shrink as an outer “jacket,” plus quality loom and clamps, greatly extends life. Where connectors sit low in the bilge or see washdown, add chafe guards and route away from water traps.

👉 Create watertight joints using Haisstronica heat shrink solder sleeves—tap to shop.

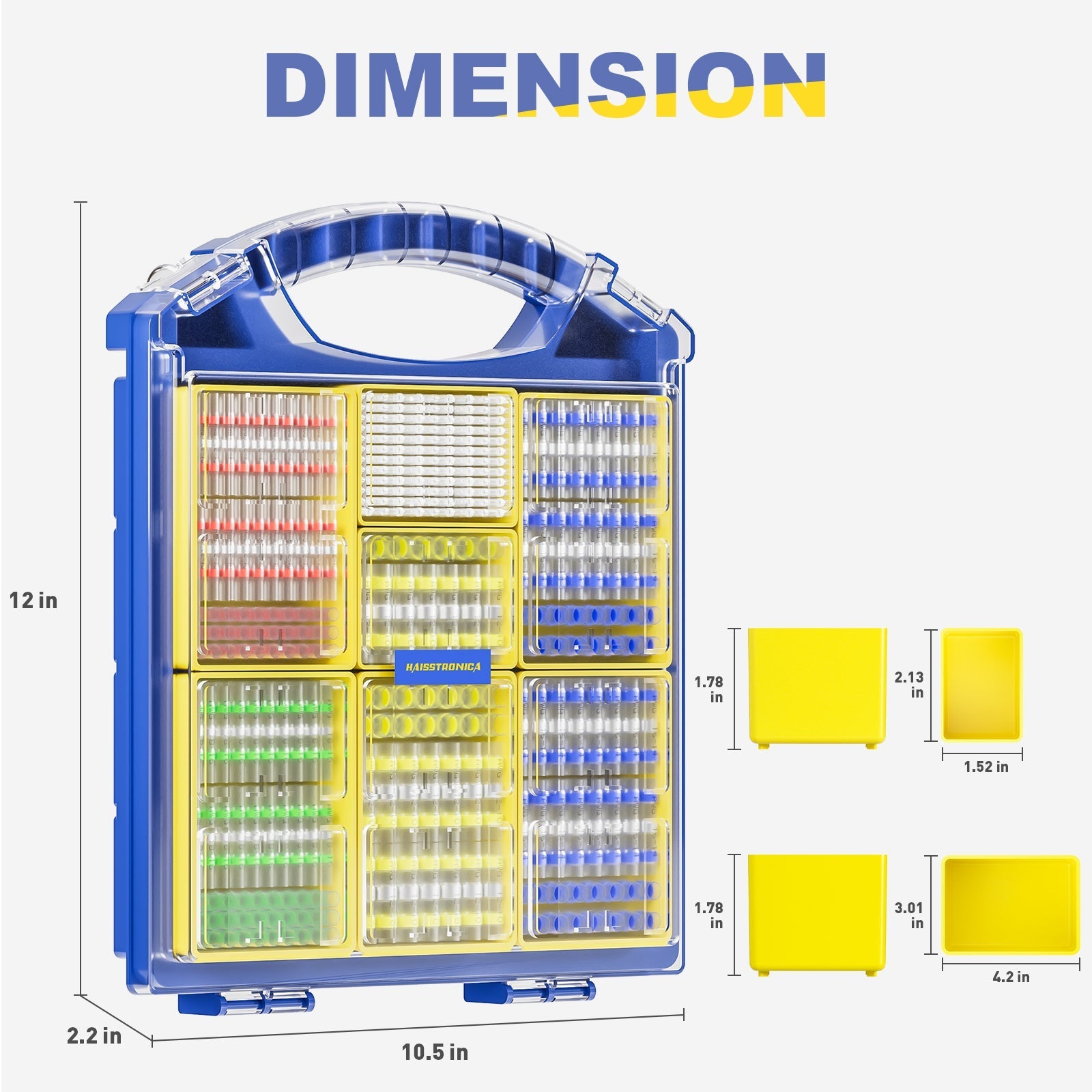

Size & Form Factors — solder on wire connectors

Unlike generic inline solder wiring connectors, the marine environment forces you to consider not only conductor cross-section (AWG/mm²) but also insulation diameter, overlap length, and physical profile of the finished joint. Use this sizing workflow to get a leak-free splice that passes a tug test.

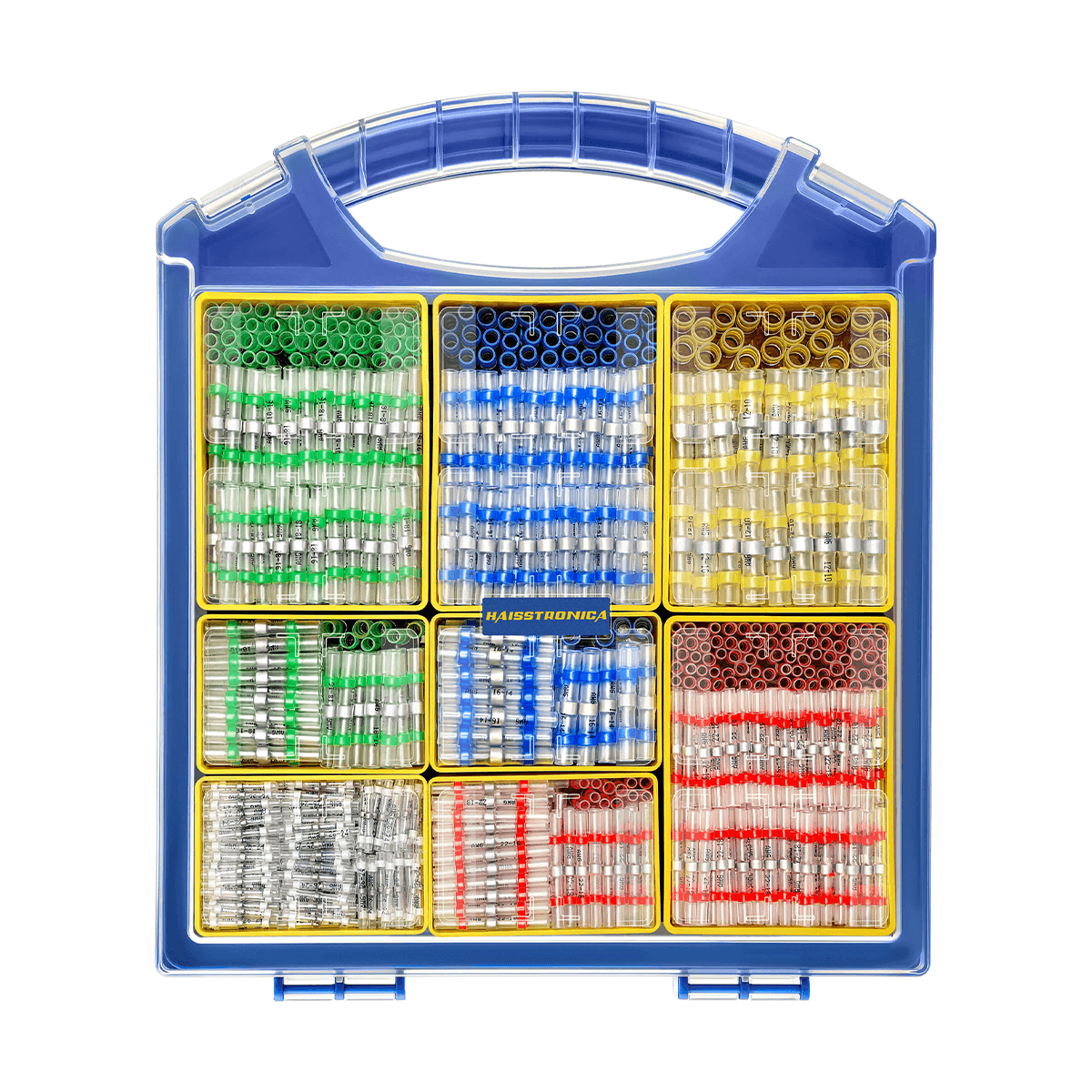

1) Map AWG to color (then check mm²)

Quality solder seal connector kits follow common color codes:

-

White: 26–24 AWG (~0.14–0.25 mm²)

-

Red: 22–18 AWG (~0.34–0.75/1.0 mm²)

-

Blue: 16–14 AWG (~1.5–2.5 mm²)

-

Yellow: 12–10 AWG (~4.0–6.0 mm²)

These ranges overlap slightly by brand, so confirm the printed AWG on the tube or the tray label. On boats you’ll also see metric cable; keep a quick chart handy (e.g., 1.5 mm² ≈ 16 AWG, 2.5 mm² ≈ 14 AWG, 4 mm² ≈ 12 AWG).

2) Measure insulation O.D. (decides shrink ratio)

Two identical AWG conductors can have different jacket O.D.s (sensor cable vs. primary). If one side is significantly slimmer, choose a sleeve with higher shrink ratio or add a short “shim” of thin wall heat-shrink on the small side before sliding on the sleeve. This ensures the adhesive bands land on insulation, not bare copper.

3) Set correct conductor overlap

Strip just enough so the strands overlap under the solder ring by ~6–8 mm (¼–⅜ in). Too little overlap invites pull-out; too much creates a long rigid section that’s harder to support.

4) Mock-fit before heat

Slide the sleeve onto one insulated side and dry-fit the joint. Confirm (a) the solder ring will sit centered on the overlap, and (b) the adhesive bands will each end up fully on insulation. If the bands would partly sit on bare copper, you chose a sleeve that’s too short or stripped too much insulation.

5) Heat sequence matters (ring, then bands)

-

Heat the solder ring first until it fully collapses and turns glassy-shiny, visibly wicking into both strand bundles.

-

Sweep heat outward to activate and shrink the adhesive bands, watching for a continuous bead to form at each end.

-

Let cool before any tug or clamp install.

6) Plan your strain relief

Even a perfect sleeve fails prematurely if it’s allowed to bend at the rigid joint. Use cushioned clamps, loom, and generous radius routing so the splice lives in a low-strain segment of the run. On bulkheads or masts, add seal connectors or grommets where the harness passes through.

Form factors and specialty sleeves

Beyond straight butt sleeves, some kits include variants for tight quarters or multi-branch splices. A few considerations:

-

Short-body sleeves: Useful in crowded conduits but leave less room for adhesive bands—be extra sure they land on insulation.

-

Higher shrink-ratio tubes (4:1): Better when one side is thin-wall or tinned-fine-strand that compacts a lot.

-

Color-coded assortments: Faster picking in dim engine rooms.

-

Combo kits: Pair solder on connectors with a small assortment of solderless connectors (e.g., ring/spade terminals) and adhesive-lined heat-shrink for terminations at bus bars.

Sizing sanity check: If you routinely handle the full small-boat range (26–10 AWG) and want consistent marine-grade materials, the Haisstronica 180PCS kit keeps the sizes and colors sorted so you can pick correctly the first time.

Where solder on wire connectors shine aboard (and where they don’t)

Shine:

-

Lighting circuits (cabin, courtesy, nav) in dry or lightly damp spaces.

-

Sensor and control leads (bilge float switch pigtails extended within a junction box above the splash line).

-

Electronics accessory branches behind panels, where a neat seal and small profile help with serviceability.

Avoid:

-

High-current conductors (battery, windlass, bow thruster, inverter). Use listed lugs + correct crimp tooling + adhesive shrink.

-

Constant-flex segments (mast hinge loops, steering columns) where the rigid solder zone would be a fatigue initiator.

-

Immersion zones (in bilge water). Even sealed splices should be routed above the wet line with drip loops; for unavoidable damp areas use junction boxes rated for the environment.

Decision rule: If you can support the splice to eliminate flex and locate it in a dry, protected spot—solder on wire connectors are viable and time-efficient. If not, choose a mechanical crimp with robust strain relief.

👉 Save time with Haisstronica heat shrink with solder connectors—fast, consistent bonds

Field checklist for marine-grade results

-

Use tinned copper wire on both sides whenever possible.

-

Pick a sleeve whose AWG/mm² range matches the conductors and whose shrink ratio suits your insulation O.D.

-

Verify solder ring flow (shiny, continuous), adhesive beads at both ends, and no voids.

-

Add strain relief (loom, cushioned clamps, correct bend radius).

-

Route with drip loops and away from water pooling.

-

Label the harness and document the splice location for future service.

Conclusion

Marine wiring is unforgiving, but it rewards discipline. When you choose the right materials and work within their strengths, solder on wire connectors can be a smart, efficient way to create sealed, low-resistance splices for branch circuits and electronics aboard. Focus on tinned conductors, fluxed low-melt solder rings, clear marine-grade tubing with dual adhesive bands, correct AWG/mm² sizing, and thoughtful strain relief. For high current, continuous flex, or immersion-risk runs, step up to listed lugs or adhesive-lined crimp-and-seal butt splices.

Our Top User-friendly Picks

When reliability matters, trust Haisstronica. Each soldered connector floods the joint with adhesive-lined protection, then cools to a long-lasting, weatherproof seal. The heat-shrink tubing absorbs scuffs and strain, preserving conductivity in harsh environments. Polyolefin sleeves show the wire gauge for fast selection. For projects where soldering connector performance outlasts temporary fixes and solderless connectors, choose our butt splices to keep circuits secure on vehicles, boats, and outdoor lighting.

If you’d like a ready-to-stow kit that matches these criteria and covers 26–10 AWG with the standard marine color codes, consider the Haisstronica 180PCS Heat-Shrink Solder-Seal Wire Connectors set:

👉 Get the kit here

Sources & Further Reading (authoritative references)

-

ABYC E-11 (AC & DC Electrical Systems on Boats)

-

UL 486A-486B (Wire Connectors)

-

TE Connectivity—Soldersleeve Devices (Application Guidelines)

-

NASA Workmanship—Soldered Electrical Connections & Heat-shrink practices