Introduction

When working on any electrical or automotive project, using the right wire connectors is critical for safety and reliability. Wire connectors securely join two or more wires, insulating the connection to prevent short circuits or electrical shocks. In fact, connectors keep live wires covered and ensure they don’t accidentally touch metal surfaces or other conductors that could cause a spark or failure. For DIY beginners and seasoned electricians alike, understanding the most common types of wire connectors – and how to use them – is an essential skill. Whether you’re repairing home wiring or upgrading automotive electrical connectors, choosing the proper connector ensures a solid, long-lasting bond. From simple twist-on caps to rugged heat shrinkable wire connectors for cars and boats, this guide will break down the definition of wire connectors, common connector types, how to use them, typical application scenarios, tips on selecting the right connector, and FAQs. By the end, you’ll know exactly which types of wire connectors to use for your project and how to install them like a pro, boosting your confidence (and your project’s safety).

Definition of Wire Connectors

Wire connectors – sometimes called electrical connectors or terminals – are devices used to join electrical wires together, either permanently or temporarily, with a safe, insulated connection. Most connectors consist of a flame-retardant plastic or nylon outer shell and an internal metal insert. The metal insert (often a tin-plated copper sleeve or a spring steel coil) grips the stripped wires, while the outer shell insulates the joint. This design prevents any exposed conductors, reducing the risk of short circuits and electrical shocks. In practice, using a wire connector is straightforward: you strip the insulation off the wire ends, insert them into the connector, and secure the connection (usually by twisting, crimping, or heating, depending on the connector type). A good connector will hold the wires tightly and keep out air and moisture, ensuring a low-resistance electrical path that won’t corrode over time. High-quality connectors (like Haisstronica’s) are often UL-listed and meet safety standards to guarantee a dependable connection that won’t easily fail.

What are the most common connector types? In electrical work, there are several common categories of wire connectors used across homes, vehicles, and industrial projects. The most common wire connector types include:

-

Twist-On Connectors (Wire Nuts): These are plastic caps with internal threaded springs. You insert stripped wire ends and twist the connector, which “nut”-locks the wires together. Twist-on connectors are extremely popular in residential and light commercial wiring – for example, connecting house wires in junction boxes or lighting fixtures. They come in various sizes and colors to match different wire gauges. Wire nuts are cheap, reusable, and reliable for indoor use, but they are not typically waterproof. (Haisstronica does not produce twist-on connectors, focusing instead on crimp and heat-shrink styles preferred for automotive and marine use.)

-

Crimp Connectors (Terminals and Splices): Crimp connectors use a crimping tool to compress a metal sleeve onto the wires, forming a strong mechanical and electrical bond. This category includes butt connectors (also known as butt splices) that join two wires end-to-end, as well as various terminal connectors like ring terminals, spade connectors, and bullet connectors used to attach wires to components. Crimp connectors are widely used in automotive, aerospace, and industrial applications because of their vibration resistance and durability when properly crimped. We will discuss butt connectors and spade terminals – two of the most common types – in more detail shortly, since they are especially important for automotive and electrical DIY projects.

-

Push-In Connectors: These are insulated blocks that allow you to simply push stripped wire ends into slots, where an internal spring clamps them in place. Push-in wire connectors (often seen in modern lighting or building wiring) make it easy to join multiple wires without twisting or tools. They save time and space in tight electrical boxes. However, they are generally for indoor use and not as robust in high-vibration environments as crimped connections. A related innovation are lever connectors (like Wago® connectors), which have small levers you lift to insert wires and then clamp down. Lever connectors are reusable and great for prototypes or when you may rewire connections, but they can be bulkier and more expensive than push-in or crimp connectors.

-

Quick-Disconnect Connectors: This refers to connector pairs that can be easily connected and disconnected, often flat blade-type terminals. The most common are spade connectors (also called spade terminals or fork connectors) which come as male/female pairs. A male spade is a flat blade, and the female spade is a receptacle; they slide together to complete a connection and pull apart for disconnection. Spade connectors are heavily used in automotive wiring (for example, to connect to speaker terminals, switches, or relays) because they allow quick removal and replacement of components. Similar quick-disconnects include bullet connectors (round male/female plug pairs) which were common in older cars, and specialty taps like T-tap connectors that let you tap into an existing wire without cutting it (useful for adding a new circuit in automotive installs). Quick-disconnects are convenient, but for the most secure splice, many electricians still prefer a good crimped butt connector for critical joins.

-

Solder and Heat-Shrink Connectors: These are a more recent popular option that combine soldering and insulating in one step. Sometimes called solder seal wire connectors or “solder & seal butt connectors,” they look like a piece of heat-shrink tubing with a ring of low-melt solder in the middle and adhesive lining. To use them, you insert stripped wire ends overlapped inside the tube and then heat it with a heat gun. The solder ring melts and fuses the wires, while the tubing shrinks and the adhesive seals the connection. The result is a soldered butt splice that is also insulated and waterproof – all without using a separate soldering iron or crimp tool. These connectors are very popular for automotive, marine, and outdoor wiring because they create a robust, low-resistance joint that’s protected from the elements. Haisstronica’s solder & seal connectors, for example, use quality solder rings with built-in flux and achieve a fully soldered connection just with heat. We’ll cover how to use both crimp and solder-style connectors in the next section.

In summary, the most common wire connectors can be categorized as twist-on, crimp-type (including terminals like spade, ring, butt splices, etc.), push-in/lever, quick-disconnect, and solder-seal heat shrink connectors. Each type has its ideal uses: twist-ons for home wiring, crimp splices and terminals for vehicle and equipment wiring, push-in and lever connectors for fast or temporary connections, and solder heat-shrink connectors for maximum reliability in harsh conditions. Now that we know what they are, let’s see how to actually use some of these connectors in practice.

Operation Steps: How to Use Wire Connectors

Using wire connectors correctly ensures a safe and long-lasting electrical connection. In this section, we’ll go through a general step-by-step process for one of the most common connector types – the butt splice connector – which covers many principles applicable to other connectors as well. We’ll focus on heat shrink butt connectors (the kind often used in automotive and marine repairs) and mention notes for solder seal connectors. Before starting, always remember: Safety first – disconnect power to any circuit you’re working on, and wear safety glasses when stripping or crimping wires.

Step 1: Strip the Wires: Using a wire stripping tool, remove about 1/4 inch (6 mm) of insulation from the end of each wire you plan to connect. Be careful not to nick the metal conductor; many wire strippers have gauge settings to help avoid cutting into the copper strands. Stripping too little insulation will result in a weak connection, so make sure enough bare wire is exposed to reach all the way into the connector barrel. Conversely, don’t strip too much – you shouldn’t have bare conductor exposed outside the connector after crimping.

Step 2: Insert the Wires into the Connector: Take your butt connector (ensure it’s the correct size for your wire gauge; most connectors are color-coded: e.g., red for 22–16 AWG, blue for 16–14 AWG, yellow for 12–10 AWG) and insert the stripped end of one wire into one side of the connector. Insert the other wire into the opposite side of the connector’s metal tube until the two wires’ ends meet in the middle of the butt splice For a solder seal connector, you would first twist the two stripped wire ends together and then center the solder ring over the twisted section. Ensure that the wire insulation butts up against the connector’s internal metal stop – no copper should be exposed outside the connector.

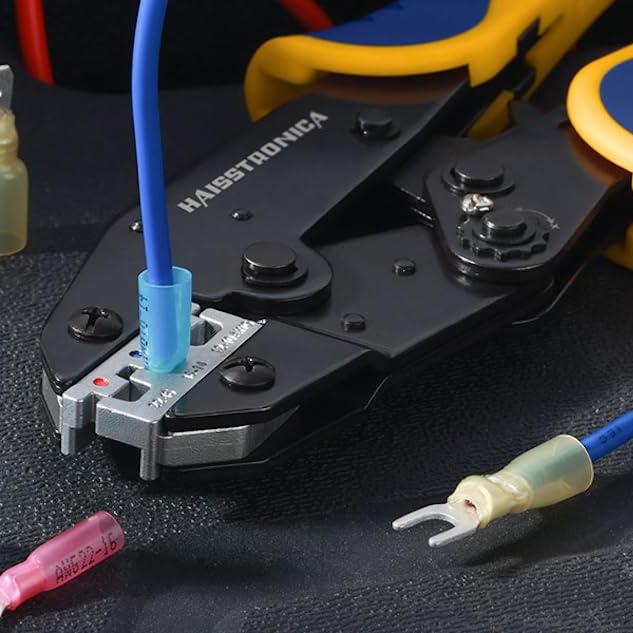

Step 3: Crimp the Connector: Place the butt connector into the appropriate crimping die on your crimp tool (match the connector’s color or the wire gauge to the die label). For insulated terminals like heat shrink butt connectors, a ratcheting crimper designed for insulated terminals works best, as it applies even pressure until fully crimped. Squeeze the crimper firmly until it completes the crimp – you’ll usually feel it release when done. A proper crimp will indent the connector and lock the wire in place. Tip: Do not crimp the same spot twice or use two crimps on one connector; one well-placed crimp in the center of each barrel is sufficient if done correctly. After crimping, give each wire a gentle tug to verify it’s securely held and won’t pull out. If a wire slips out, the crimp may have been misaligned or the wrong connector size was used – you’ll need to cut it off and try again with a new connector.

Step 4: Apply Heat (for Heat Shrink Connectors): Now, use a heat gun (or another appropriate heat source) to shrink the connector’s insulation. Sweep the heat gun back and forth over the connector evenly. As the tubing heats, you’ll see it start to shrink tightly around the wire, and if the connector has adhesive lining, you might notice a bit of adhesive oozing at the ends. In the case of heat shrink butt connectors with solder, continue heating until you see the solder ring melt and flow into the wire strands. The tubing should become slightly translucent and you may hear a faint sizzle from the melting adhesive – that’s normal. Important: Keep the heat gun moving to avoid burning the insulation; don’t hold it in one spot for too long. Once the heat shrink has fully recovered (shrunken) and you see the solder has melted (if applicable), remove the heat and let the connector cool undisturbed for a minute. The result will be a tightly sealed splice that is waterproof and strain-relieved.

Step 5: Inspect and Test: After the connector cools, inspect the connection. The tubing should be snug around the wire with no gaps, and in the case of a solder connector, you should see a shiny band of solder in the center indicating the solder flowed properly. Give the wires another light tug to ensure the crimp (or solder joint) holds. If you have a multimeter, you can do a quick continuity or resistance check across the connection – it should show near zero ohms if everything is solid. Finally, if the circuit was powered, restore power and verify that your connection works as intended (for example, the device turns on, the light illuminates, etc.).

That’s it – you’ve made a secure splice with a butt connector! This same basic process (strip, insert, crimp/solder, and seal) applies to many connector types. For ring or spade electrical connectors (automotive style), you would strip the wire and crimp it into the metal terminal, then attach the terminal to a stud or screw. For push-in connectors, you simply strip the wire and push it into the hole until it locks. And for wire nuts, you’d strip the wires and twist the connector over them until tight.

Application Scenarios for Common Connectors

Wire connectors are used in virtually every electrical scenario – from household repairs to complex automotive systems. Here are some typical application scenarios and which wire connector types are commonly used in each:

-

Automotive Wiring: Cars, trucks, motorcycles, RVs, and boats all rely on dozens of connectors. Automotive wire connectors need to withstand vibrations, temperature extremes, and sometimes moisture. For splicing wires in a vehicle (such as repairing a broken wire or installing aftermarket lights or a car stereo), butt connectors are frequently used because they maintain the continuity of the wire in a straight line. Often these are heat shrinkable wire connectors to ensure a waterproof seal for engine bay or under-carriage wiring. For connecting wires to components like speakers, switches, or sensors, spade connectors and bullet connectors are common. For example, a car horn or headlight might use a female spade terminal to plug onto a relay or fuse box, making it easy to replace parts without cutting wires. Ring terminals are used to connect wires to battery posts or ground screws – you’ll see ring connectors on car battery cables and ground wires bolted to the chassis. In automotive applications, using heat shrink connectors is often wise because vehicles are exposed to water (rain, road splash) and solvents; the heat shrink insulation with adhesive keeps connections dry and secure. Additionally, solder seal connectors are popular for aftermarket wiring of off-road lights or trailer harnesses, where a durable, sealed splice is needed without bulky connectors. Overall, if you’re working on a vehicle, you’ll likely encounter crimped terminals and butt splices everywhere from the engine compartment to the tail lights – they are the backbone of automotive electrical repairs.

-

Marine and Outdoor Equipment: Boats, jet skis, ATVs, and outdoor lighting systems all face even harsher conditions with water exposure and corrosion. In these cases, heat shrink wire connectors are invaluable. For instance, when wiring a boat trailer’s lights, using heat shrink butt connectors or butt splice connectors with solder can prevent corrosion from saltwater exposure. Marine-grade connectors (like Haisstronica’s heat shrink line) are often rated to IP67 waterproof standards, meaning they can be submerged in water without failing. This is crucial in preventing failures in bilge pumps, navigation lights, or outdoor landscape lighting. Spade electrical terminals (forks and rings) are also used in marine settings for battery connections and bus bars, but again the heat shrink insulated versions are preferred to seal out moisture. In short, for any wiring that sees the outdoors – from solar panel arrays to garden light fixtures – heat shrink connectors provide peace of mind that your connections are sealed from rain and humidity.

-

Home Electrical and DIY Projects: Inside the home, twist-on wire connectors (wire nuts) are extremely common for joining wires in switch boxes, outlets, and ceiling lights. For example, when installing a new light fixture, you’ll likely twist the fixture’s leads to the house wires and secure them with a colored wire nut. They’re perfect for indoor, dry locations and allow for connecting multiple wires (like pigtailing a circuit). For DIY electronics or appliances, small crimp connectors like forked spade terminals or quick disconnects might be used – for instance, connecting wires to a speaker or an appliance’s control board. Lever connectors have also become popular for DIY enthusiasts wiring things like smart home devices, because you can easily open and reuse the connections if needed (great for prototyping circuits). If you’re repairing an extension cord or a lamp cord, you might use an inline butt splice connector (with heat shrink over it) or a crimp cap to reconnect a cut wire. Always match the connector to the wire gauge and current requirement – home wiring carrying 15-20 amps should only be joined with connectors rated for that amperage (usually indicated by their size and UL listing).

-

Industrial and Panel Wiring: In industrial control panels or machinery, you’ll often find wire ferrules on the ends of wires that go into screw terminals. Ferrules aren’t exactly “connectors” joining two wires, but they are crimped onto a stranded wire to keep the strands together for a reliable connection under a screw terminal block. Ring and fork terminals are used extensively for wiring to studs, relays, or grounding points in equipment. For quick servicing, disconnect terminals (spades/bullets) might connect sensors or motors so they can be replaced without re-wiring. Industrial connections also include specialized plug connectors (like multipin aviation connectors, etc.), but those are beyond the scope of “common” connectors that the average DIYer uses. However, the principles remain the same – a good crimp or solder joint, secure mechanical attachment, and insulation.

In all these scenarios, using the correct connector improves safety and performance. A well-crimped butt wire connector in a car’s wiring loom will prevent a sudden electrical failure on the road. A waterproof solder & seal connector on a boat will keep the navigation lights shining trip after trip. And a simple wire nut in a junction box will keep a home’s lights on without danger of arcing. Understanding which connector to use where comes with experience, but this guide and the above examples should give you a strong starting point.

Buying Guide: How to Choose the Right Connector

With so many types of connectors available (from simple butt connectors to advanced solder wire connectors), how do you choose the right one for your needs? This buying guide will walk you through the key factors to consider and some tips for selecting quality connectors, especially for automotive and electrical DIY use.

1. Match the Connector Type to Your Application: First and foremost, consider what you’re trying to connect. Is it two cut wires that need splicing back together? Then a butt splice is likely the best. Are you terminating a wire to attach it to a battery or screw terminal? Look at ring terminals or spade terminals. Need a removable connection between two wires? Bullet connectors or spade connector pairs might be ideal. For joining house wires (solid core) in a junction box, twist-on connectors are code-compliant and convenient, whereas in an automobile, you’d favor crimp connectors or solder seal splices for vibration resistance. Also decide if you need the connection to be permanent or if you might disconnect it frequently – permanent splices (butt, solder) are more secure, while quick disconnects (spades, bullets, lever connectors) allow easier separation. In summary, tailor the connector style to the project’s requirements: electrical butt connectors and crimp terminals for most vehicle/boat fixes, wire nuts or push-ins for home wiring, and solder connectors for when you want an especially robust, sealed join.

2. Wire Gauge and Connector Size: Connectors are typically rated for a range of wire gauges. Using the correct size is essential. Too large, and the wire may not crimp tightly; too small, and you won’t fit the wire in. Most common crimp connectors are color-coded by size: red for 22-16 AWG, blue for 16-14 AWG, yellow for 12-10 AWG. Always check the product description – for example, if you have a 18 AWG wire, use a red connector (since 18 AWG falls in the 22-16 range). If you’re working with very small wires (22 AWG or smaller) or very large wires (8 AWG or bigger), you might need specialized connectors (like telecommunication gel caps for tiny wires, or heavy-duty lugs for large cables). Never force a wire into a connector not meant for it. If in doubt, buy an assorted kit of connectors that covers the range of gauges you might encounter.

3. Insulation and Environment: Think about where the connection will be located. If it’s in an area with moisture (outdoors, engine bay, marine, etc.), opt for heat shrink insulated connectors. These often say “weatherproof” or “marine-grade” on the package. They have a heat shrink sleeve (sometimes with adhesive) that you’ll shrink after crimping to seal the joint. For the ultimate protection, the heat shrink butt connectors with solder (solder & seal) provide both a soldered joint and a fully sealed insulation in one. On the other hand, if you’re working in a dry indoor environment (like inside an appliance or a wall), standard vinyl or nylon insulated connectors or even non-insulated (with separate heat shrink tubing you add) can suffice. Temperature is another factor – under-hood automotive connectors should handle heat, so look for high-temperature ratings. Vibration is a factor too: crimp connectors are generally better than solder joints in high-vibration spots unless the solder joint is fully strain-relieved (which solder seal connectors do provide by shrunk tubing).

4. Quality of Materials: Not all connectors are created equal. The internal metal tube or terminal is the critical part of a connector. High-quality connectors use tinned copper inserts because copper is an excellent conductor and tin plating adds corrosion resistance. Cheaper connectors might use brass or even aluminum inserts, which have higher resistance and can corrode or crack more easily. For example, Haisstronica’s connectors use pure tinned copper cores for maximum conductivity and durability. The insulation material is also important – nylon and polyolefin (for heat shrink) tend to be more durable than basic PVC. Nylon crimp connectors are less likely to split when crimped, and dual-wall polyolefin heat shrink tubing with adhesive will seal better than thinner single-wall tubing. If you need the connection to be extra secure, look for heat shrink connectors with a 3:1 shrink ratio (shrinks to one-third its size) and adhesive lining, which provide a tight seal around the wire. Also consider connectors that are UL listed or MIL-SPEC if you want proven performance. Reputable brands (like Haisstronica, 3M, etc.) will advertise meeting certain standards (UL, CE, ISO) which can be an assurance of safety and quality. When buying online, it’s wise to read reviews or see if the product description mentions tests like pull force or waterproof ratings. For instance, a good butt connector should withstand a strong pull (some brands test to over 150 Newtons of force) without the wire coming out.

5. Connector Kits vs Individual Pieces: If you are starting from scratch, you may want to buy an assorted wire connector kit. These kits often provide a variety of connectors (butt splices, ring terminals, spades, etc.) in multiple sizes. For example, a popular choice is the Haisstronica 660PCS Heat Shrink Butt Connectors Kit (AWG 22-10) which includes hundreds of connectors in red, blue, and yellow sizes to cover common gauges. A kit gives you the flexibility to tackle different tasks and usually comes in a handy organizer box. Some kits even come with tools – for instance, there are sets that include a crimping tool and heat shrink connectors together, which can save money and ensure you have a correctly sized crimper for the connectors. If you mostly need one type of connector (say you’re doing a car stereo and only need butt connectors), you can buy packs of just that type in the size you need. However, many DIYers find that once you start tinkering, having an assortment on hand is very convenient. Look at the contents of the kit and make sure it has the types you expect to use (if you need spade connectors, does the kit include them, or is it only butt splices? Some kits are specific).

6. Tools Required: While not a connector itself, the tools you use go hand-in-hand with connector selection. If you’re buying crimp connectors, you will definitely need a proper wire crimping tool. A ratcheting crimper with interchangeable dies for insulated terminals is a great investment for reliable crimps. Additionally, a good wire stripper that cleanly strips insulation without cutting strands will make your connector installation easier. For solder seal connectors, a decent heat gun is needed – preferably one with adjustable temperature so you don’t scorch the tubing. Some connector kits come with a basic heat gun or mini torch; otherwise, budget for one. Don’t forget heat shrink tubing if you use non-insulated connectors, and perhaps a multimeter for testing your connections. In short, choose connectors that you have the ability to install properly with your tools. If you lack a crimper and don’t want to buy one, you might lean towards solder & seal connectors (no crimper needed), but if you’re doing a lot of wiring, investing in a good crimper and using crimp connectors is well worth it for speed and consistency.

By considering these factors – connector type, size, environment, quality, kit vs individual, and required tools – you can select the optimal connectors for your project. A final piece of advice: don’t cheap out on critical connections. A few extra dollars for high-quality heat shrink wiring connectors or a better brand of terminals can make the difference between a connection that lasts years versus one that fails at the worst time.

FAQ (Frequently Asked Questions)

Q1: What’s the difference between using a butt connector and just twisting wires together with electrical tape?

A1: The difference is huge in terms of reliability and safety. Simply twisting wires together (even if you tape them) is not a secure connection – the wires can loosen over time, oxidation can increase resistance, and there’s no strain relief or proper insulation. A butt connector (especially a crimped or soldered one) mechanically binds the wires and insulates them, making the connection strong and protected. Tape can unravel or moisture can get in, leading to shorts or failure. Always use an appropriate connector rather than an improvised join. The only exception might be a very temporary test connection, but for anything permanent, connectors like butt splices or wire nuts are the correct solution.

Q2: Are solder seal connectors better than crimp connectors?

A2: Solder & seal connectors and crimp connectors both have their advantages, and “better” depends on the application. Solder seal (heat shrink solder) connectors create a solid soldered joint which can offer slightly lower electrical resistance and a fully sealed connection without needing a crimp tool. They are great for quick repairs where you have a heat gun handy and want a waterproof result – e.g., fixing a wire on a boat or car in the field. Crimp connectors, on the other hand, require a crimp tool but are very fast to use and don’t heat the wire (soldering can potentially wick solder down the wire and make it stiff or brittle if overdone). In high-vibration environments, a good crimp is extremely reliable, and it’s the industry standard in automotive production because it’s fast and consistent. Solder connectors have become popular for DIY, but some professionals still prefer crimps for critical automotive/aviation use because a crimp, when properly made, has a proven track record and is slightly more flexible at the ends of the joint (solder joints can act as a stress riser at the edge of the solder). That said, a heat shrink solder connector that’s made correctly is waterproof and strong, and many DIYers find them very convenient. In summary: use crimp connectors when you have the right tools and need speed and proven durability; use solder seal connectors when you want an easy, soldered solution without a crimp tool. Both, especially the heat-shrink varieties, will serve you well in most DIY scenarios.

Q3: Can I use automotive connectors for home electrical wiring (or vice versa)?

A3: It depends on the connector and the situation. Many connectors can cross applications – for example, a ring terminal doesn’t care if it’s on a car or a home circuit, as long as the wire size and current are within range. However, there are some important distinctions: Twist-on wire nuts are commonly used in home AC wiring (120V/240V) and are UL listed for that purpose; they are usually not used in vehicles (vehicles typically deal with DC voltage and more vibration). Conversely, crimp butt connectors are used all the time in cars but are not typically seen in home wiring behind outlets – not because they wouldn’t work, but because wire nuts or screw terminals are the norm per electrical code for building wiring. Another aspect is temperature and ratings: automotive connectors might not be rated for the high voltages in home wiring (120V AC) unless explicitly stated. Always check the connector’s voltage and amperage ratings. Automotive wire connectors often are rated for 12V systems (and up to maybe 48V DC) and carry up to certain amps, but a home uses 120V AC which is a different scenario. For safety and code compliance, use connectors as they are intended – e.g., use UL-listed wire nuts for joining house wires, and use automotive-grade connectors for automotive wires. If you do need to use a crimp connector in a home project (say for low-voltage doorbell wires or thermostat cables), that’s generally fine. Just be cautious about mixing in automotive connectors for mains voltage projects unless you know they meet the necessary standards.

Q4: How do I ensure a crimp connector is fully crimped correctly?

A4: A proper crimp will deform the connector’s barrel around the wire tightly, and there are a few checks you can do. First, use the correct die size on a ratcheting crimp tool – these tools usually won’t release until the crimp is compressed enough. When you crimp, you should feel the tool bottom out and then release. After crimping, inspect the crimp: the barrel typically has an indentation from the crimper, and it shouldn’t spin or wiggle in the insulation. Do a pull test – hold the connector and firmly tug the wire; it should not move or come out. If it does, cut it off and redo it, because a loose crimp will cause resistance and heating. You can also check that the wire’s insulation is very close to the edge of the barrel – no large gaps. One more tip: make sure you strip the right amount of insulation (usually about 1/4″ to 3/8″ depending on connector). If you strip too much, you might see bare wire outside the crimp which is not good; too little and the wire might not reach the center of the barrel. Follow the manufacturer’s instructions if available – some connectors come with guidelines (for example, “insert wire until it stops, insulation should be inside the barrel”). After a few successful crimps, you’ll get a feel for it. When in doubt, practice on a scrap piece of wire and test the crimp’s strength.

Q5: Why are there different colors of butt connectors and do the colors matter?

A5: The colors on butt connectors (and ring/spade terminals) indicate the wire size (gauge) they are designed for, and sometimes the material of insulation. This is a standardized system for most insulated crimp connectors: Red typically fits 22-16 AWG wires, Blue fits 16-14 AWG, and Yellow fits 12-10 AWG. Some brands have additional colors or clear ones for other ranges, but red/blue/yellow are the most common for the sizes mentioned. It’s important to use the right color (size) for your wire – if you crimp a 18 gauge wire in a yellow connector (meant for 12-10 gauge), it will likely not crimp tightly because the wire is too small for that barrel. Conversely, a 10 gauge wire won’t even fit into a blue or red connector. So yes, the colors matter in terms of sizing. Beyond size, sometimes color can denote insulation type: for instance, you might see pink connectors for 26-24 AWG in some kits, or clear heat-shrink connectors that cover various sizes (with color-coded bands or solder rings inside instead). Always read the package or kit chart – it will list which colors correspond to which gauges. If you’re unsure and have an unlabeled assortment, you can gauge by eye or test fit a stripped wire; it should go in snugly and fill the metal barrel, but not be so large that it frays or jams. Following the color code is an easy way to ensure you’ve got a compatible connector for your wire.

Q6: Where can I buy good quality wire connectors and what brand is recommended for DIYers?

A6: Quality connectors are available from many sources: hardware stores, automotive parts stores, and online retailers. For DIY beginners, it’s often convenient to buy an assortment kit online that includes a variety of connectors. When choosing a brand, look for ones with good reviews for quality. Haisstronica is a popular brand for both automotive and electrical connectors – they specialize in heat shrink connectors, solder seal connectors, crimping tools, etc., and are known for industrial-grade quality at reasonable prices (they use tinned copper cores, adhesive-lined heat shrink, and have certifications on their products). Other well-regarded brands include 3M (particularly for premium cold-shrink connectors and electrical tapes), Panduit, TE Connectivity/AMP, and Molex for specialized connectors. If you’re shopping on Amazon or similar, be cautious of very cheap no-name connector kits; they might use thin metal that doesn’t crimp well or poor insulation that splits. It’s worth investing a bit more in a kit from a known brand like Haisstronica, as you’ll get connectors that meet their specifications consistently. You can purchase Haisstronica connectors directly from their official website or through their Amazon storefront (which often has fast shipping in the US). Always ensure the kit or connectors you buy cover the wire gauges you need and come with any needed accessories (some kits bundle a crimper or heat gun, which can be a bonus for new users).

Ready to Get Connected? (Purchase Entry)

By now, you should have a solid understanding of the most common wire connectors and how to use them. If you’re ready to tackle your wiring project, make sure you have quality connectors on hand. You can find highly-rated connector kits and tools from Haisstronica that are perfect for DIY automotive and electrical work. For example, the Haisstronica 660PCS Heat Shrink Butt Connectors Kit (AWG 22-10) contains a comprehensive assortment of butt splices with superior heat shrink insulation – an excellent starter kit for general wiring needs. You can purchase this kit and other connector assortments directly from the Haisstronica Online Store or via their Haisstronica Amazon Storefront for quick delivery in the US. Equipping yourself with the right connectors and tools will make your DIY wiring safer and more reliable. Happy connecting, and remember: a job done with proper wire connectors is a job done right!