コネクタを「プレミアム」にする要素 – 材質の品質と内蔵はんだシールコネクタ

すべてのはんだ付けシール電線コネクタが同じように作られているわけではありません。高級コネクタと廉価版の違いは、多くの場合、材質、設計精度、そして品質管理にあります。はんだ付け・熱収縮コネクタを「高級」たらしめる主な要因は次のとおりです。

-

高級熱収縮チューブ:高級コネクタでは、低価格スリーブで一般的な 2:1 の薄いチューブではなく、高収縮率 (多くの場合 3:1 または 4:1) の厚い二重壁ポリオレフィン熱収縮チューブが使用されています。収縮率が高いということは、チューブがワイヤの周りをよりしっかりと均一に締め付けることができるため、ワイヤ絶縁体の直径が異なっていてもしっかりと密閉できることを意味します。これにより、隙間のない耐久性のある防水シールが実現します。対照的に、安価な熱収縮はんだコネクタは、薄くなったり完全に収縮しなかったりして、脆弱な部分が残る場合があります。フィールドテストでは、「高級スリーブは均一に収縮する...低級スリーブは不均一に薄くなったり、乾いた部分が残ったりする」ことが指摘されています。つまり、高品質のコネクタは、均一でマットなシールを形成し、端部に接着剤が目に見えるほど押し出されているのに対し、低価格のコネクタでは、不均一な収縮や気泡が発生することがあります。

-

高品質合金を使用した、強力で十分なはんだリング:はんだ自体は、はんだスリーブ接続の核心です。プレミアム コネクタには、ワイヤ ゲージ (AWG ごとに色分け) に適したサイズで、フラックスを内蔵した高純度の低融点合金で作られたはんだリングが含まれています。これらのリングは通常、均一な流れのためにチューブの中央に配置されています。適切に設計されたプレミアム コネクタは、はんだを溶かして被覆を剥がしたワイヤの先端から完全に吸い上げ、強固な電気的および機械的な接続を作り出します。一方、低価格のコネクタでは、はんだの量が少ない (リングが薄い) か、合金の品質が低い場合があります。トップ ブランドのコネクタと無名のバージョンを比較した業界テストでは、プレミアム コネクタのはんだがワイヤをよく濡らしたため、接続部分がワイヤ自体よりも強く保持されましたが、低価格のコネクタは、はんだの浸透性が「非常に悪い」ものでした。ワイヤ表面にはんだが飛び散っただけで、標準的な引張強度をはるかに下回る強度で引き離されました。実際、3Mの高級はんだコネクタはUL/ABYCの引張試験基準を常に上回っていました(接続部より先に電線が断線する)のに対し、安価なコネクタは簡単に破損しました。この際立った違いは、高級はんだリングが真に融着した接続を実現するのに対し、低品質のリングでは、テープで巻いた電線よりもわずかに良い程度の弱い接続しか得られないことを如実に示しています。 。

-

防水シールのための高品質ホットメルト接着剤:はんだ付け & シール コネクタの大きなセールス ポイントの 1 つは防水ジョイントですが、これは接着剤が標準に達している場合のみ実現します。プレミアム コネクタでは通常、約 80~100 °C (はんだの溶融温度未満) で溶けて隙間を埋めるEVA ホットメルト接着剤ライニング (一部の高級設計では高度なポリアミド接着剤) が使用されています。この接着剤は、冷却されると接続部の周囲に防水シールを形成し、腐食から保護します。一部の特殊なプレミアム コネクタは、船舶または自動車での使用を想定して、燃料/油に耐性のある接着剤を使用していると宣伝されています。低価格のコネクタでは、接着剤の品質や量が少なく、両端に 2 つのリングではなく 1 つの接着リングしか付いていなかったり、接着が不十分な安価な接着剤が使用されていたりすることがよくあります。その結果、時間の経過とともに接続部に湿気が入り込む可能性があります。高品質なコネクタは、適切に加熱するとチューブの両端から接着剤が目に見えてはみ出します(完全な密閉の証です)。一方、安価なコネクタは、接着剤が付着していない隙間や「乾いた」部分が残る場合があります。つまり、高品質な密閉型はんだ付けコネクタは、真に密閉された防水はんだ付けワイヤコネクタ接合部を保証します。一方、安価なコネクタは密閉されているように見えても、水が浸入し、目に見えない腐食につながる可能性があります。

-

一貫性と認証:高品質なはんだ付けコネクタのもう一つの特徴は、厳格な品質管理です。例えば、高級ブランドは、各コネクタのはんだリングが中心に完全に配置されていること、チューブとはんだ合金が業界標準を満たしていることを保証しています(UL規格やMIL規格の認証を取得しているものもあります)。中心に配置されたはんだリングは、見た目が良いだけでなく、取り付け時の「作業ミスを軽減」し、はんだが両方のワイヤーに均等に溶け込むことを保証します。位置が不均一な場合(安価な製品によくあることですが)、接続部分の片側がはんだ不足になることがあります。また、高品質なコネクタは透明なチューブに透明なはんだと接着剤を使用しているため、作業中に溶け込みや接合部の形成状態を検査できます。評判の良いコネクタの多くは、UL、CE、ROHS、または自動車規格への準拠を謳っています。これは、独立した機関による安全性と性能の検証を受けていることを意味します。安価なノーブランドコネクタは、通常、このような認証を受けていません。ある業界レビューでは、 「ノーブランドのはんだシールコネクタは絶対に購入すべきではない」と明確に述べられています。適切なテストと QA を省略するとコストを節約できますが、すべての接続で賭けに出ることになります。

まとめると、高品質のはんだ付け用ワイヤーコネクタは、優れた材料(収縮チューブ、はんだ、接着剤)と厳格な製造公差によって差別化されています。これらの特性により、コネクタはより高いストレスに耐え、外部からの要素を遮断し、安定した結果をもたらします。初期費用は高くなりますが、それは信頼性に対する代償です。安価なコネクタは、急ぎの修理や極めて低リスクの用途には適しているかもしれませんが、外観は「見栄えが良い」ように見えても、内部の接合部が劣っている場合がよくあります。プロジェクトの安全性と寿命がかかっている場合、この製造品質の違いは非常に重要です。

👉 Haisstronica はんだ配線コネクタを使用して正しく仕上げます(加熱、シール、保護)。

取り付けウィンドウとユーザーエラー – 安価なはんだ付けコネクタと高品質のはんだ付けコネクタを正しく使い分ける

優れたコネクタであっても、取り付けが不十分だと故障する可能性がありますが、プレミアムコネクタは一般的に取り付け時の誤差に対する許容範囲が広くなっています。一方、低価格のコネクタは、意図したとおりに動作させるには、ほぼ完璧な技術と条件が求められることがよくあります。これは、これらのコネクタの耐熱性と、ユーザーによるミスに対する設計の許容度に関係しています。

-

加熱要件と許容範囲:はんだシールコネクタを取り付けるには、はんだが溶けてチューブが収縮するまで接合部を加熱する必要があります。プレミアムコネクタは、一般的な熱工具に対して予測どおりに反応するように設計されています。例えば、高品質のコネクタは、標準的な1500Wのヒートガンで適切な時間内に適切に溶けます。重要なのは、プレミアム製品のチューブと接着剤が、はんだを完全に溶融させるのに必要な熱に耐えられることです。実地試験では、3Mのプレミアムコネクタははんだを完全に溶かすのに時間がかかり(わずかに高温になりましたが)、その過程で「変形、ひび割れ、変色は発生しませんでした」。 対照的に、安価なコネクタは溶けるのが遅すぎたり速すぎたりすることが多く、はんだが安全な熱レベルで流れないことがあるため、ユーザーは熱を上げざるを得なくなります。あるボートのレビューでは、格安コネクタでは、中程度の熱を使用すると「はんだが流れ始める前に熱収縮チューブが端で裂け」 、より高い熱を加えるとコネクタの中央が破裂して溶けたはんだが漏れたと指摘されています。これは、はんだが最終的に溶けるまでに、低価格コネクタのプラスチックチューブが温度に耐えられなかったために発生しました。高級ユニットには通常、必要なはんだの融点で燃えることなく収縮して密閉するチューブが使用されています。 「インストールウィンドウ」 、つまりはんだ接合を良好にするための時間と温度のスイートスポットは、高品質のコネクタの方がはるかに広くなります。指示に従えば、チューブが焦げたり、はんだが加熱不足になる可能性は低くなります。超安価なコネクタでは、綱渡りのように感じることがあります。熱が少なすぎると、はんだ接合部が冷たくなります。多すぎると、はんだが溶ける前にスリーブが焦げたり裂けたりしてしまいます。

-

フラックスとはんだの流れ:適切なはんだ付けには、酸化を除去し、はんだの流れを促進するフラックスが必要です。高品質のはんだシールコネクタは、はんだリング内に適切な量のフラックスを内蔵しています。これにより、加熱されたはんだは、外側に固まるのではなく、ワイヤの芯線にしっかりと浸透します。安価なコネクタのユーザーからは、はんだの塊が撚り線の上に乗ったままで、実際には接続されていないという報告がよくあります。これは典型的なコールドジョイントの現象です。安価なコネクタでは、フラックスのムラや不足が、成功と失敗を分ける可能性があります。良質なコネクタのはんだは、完成すると光沢を放ち、銅とフィレットを形成します。一方、 「ざらざらした灰色の残留物」や鈍いはんだは、フラックス不足またはコールドジョイントを示しています。高品質の製品は、フラックスの化学的性質やはんだ合金が優れているため、このような問題が発生する可能性がはるかに低くなります。つまり、初心者でも、はんだリングが目に見えるほど崩壊して流れ出すまで加熱すれば、強力な接続を実現できる可能性が高いということです。安価なコネクタの場合、熟練した技術者であっても、はんだがワイヤを完全に濡らさない(引張テストで判明)ことに気づき、接続のやり直しや交換が必要になる場合があります。

-

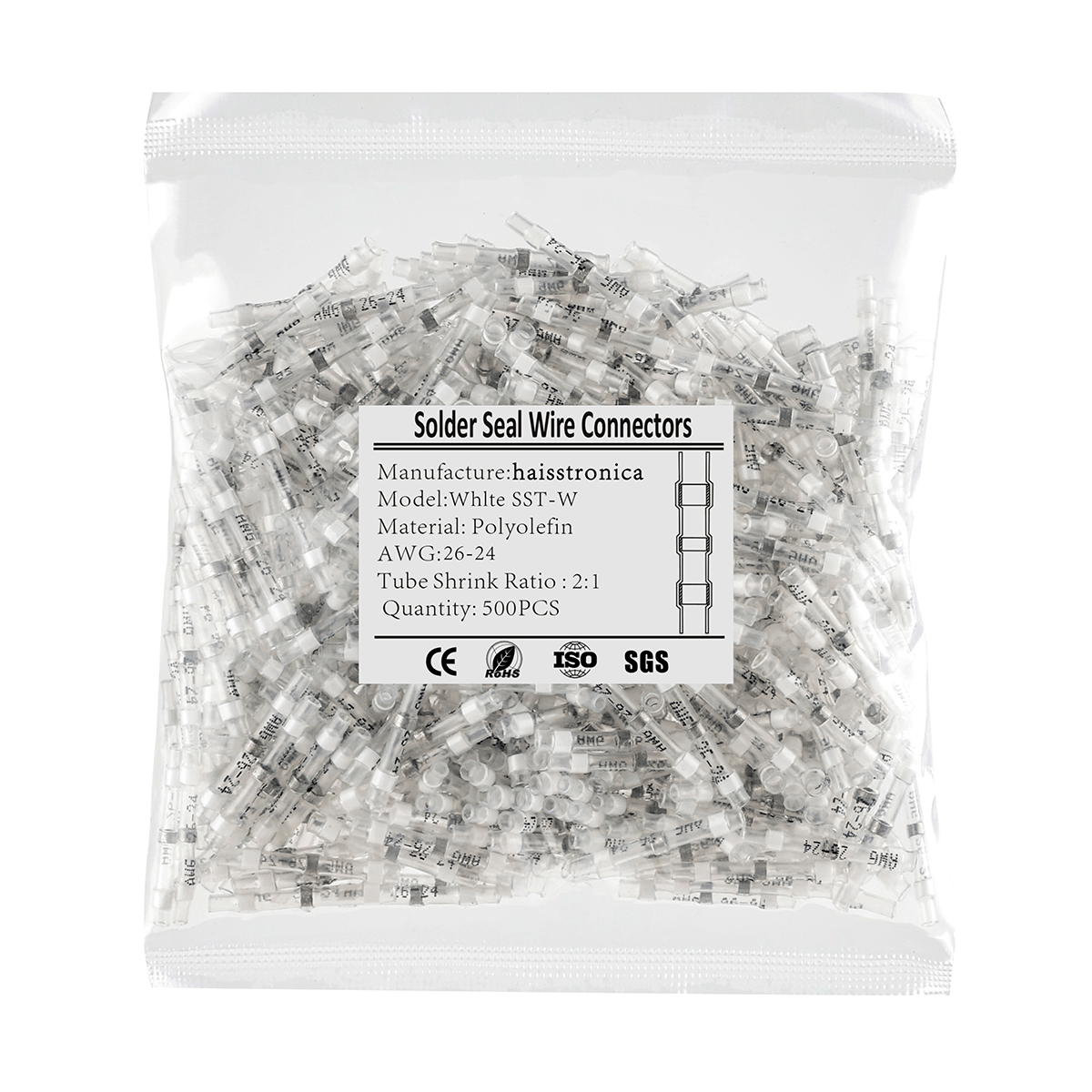

物理的な位置合わせと組み立て精度:設計上の細部が、取り付けの容易さに大きく影響することがあります。高級コネクタでは、はんだリングがチューブの中央に正確に配置されており、チューブの長さは適切な電線被覆長さに合わせて調整されています。そのため、加熱前に被覆を剥がした電線端をリングの下に正しく重ねて挿入することが簡単です。安価なコネクタでは、はんだ付け金属が中心からずれていたり、チューブの切断が不均一だったりすることがあります。これはユーザーのミスにつながる可能性があります。例えば、接合部の片側に電線の露出部分がもう片側よりも長い場合、はんだが片側に流れ込み、もう片方の電線はほとんど錫メッキされない可能性があります。Haisstronicaのエンジニアは、 「中心に配置されたリングは作業ミスを減らし、中心からずれたリングは煩わしく、作業のスピードを低下させます」と述べています。高級コネクタは、基本的にユーザーが正しい作業を行うためのガイドとなります(被覆を剥がした導体の中心位置を示すマーキングが付いているものもあります)。安価な製品では、配置について特に注意が必要です。もう 1 つの側面はコネクタのサイズです。プレミアム キットには、多くの場合、異なるワイヤ ゲージ用の明確なサイズ マーキングまたはカラー コードが含まれています (たとえば、26 ~ 24 AWG の場合は白、22 ~ 18 AWG の場合は赤、16 ~ 14 AWG の場合は青など)。これにより、接続するワイヤに対して正しいコネクタを選択できます。サイズが間違っていると、障害が発生する可能性があります (大きすぎると完全に収縮/密閉されず、小さすぎるとワイヤが入らない)。高品質キットでは、AWG ガイド チャートまたはラベルが箱に用意されているため、推測する必要がありません。対照的に、多くのお買い得パックには最小限のラベルが付いており、ユーザーが間違ったサイズのスリーブを手に取って接続不良に陥る可能性が高くなります。プレミアム コネクタの寛容な収縮率もここで役立ちます。3:1 または 4:1 の収縮コネクタは、ワイヤとコネクタのサイズのわずかな不一致に適応できますが、2:1 の低価格コネクタは密閉するためにほぼぴったり合う必要があります。たとえば、誤って理想よりも 1 サイズ大きいコネクタを使用した場合、高品質の 4:1 コネクタであればワイヤの周囲を密閉できるほど収縮する可能性があります (その操作者のエラーは許容されます)。ただし、安価な 2:1 コネクタでは、同じ状況で漏れたり外れたりする可能性があります。

-

ユーザーからのフィードバックと視覚的なヒント:はんだ付け熱収縮コネクタを正しく取り付けるには、正しく取り付けたかどうかを知ることも重要です。プレミアム コネクタは、色が変わったり、明確な視覚的インジケーターが表示されたりすることで、これを容易にします。高品質の透明チューブは、完全に加熱されると半透明に変わり、端から接着剤がにじみ出てきます。これが接合部が密閉された合図です。また、はんだリングが固い帯から光沢のある液体に変化し、電線に吸い込まれるのも観察できます。これらの変化が見られれば、接合部がしっかりしていると確信できます。一部の安価なコネクタでは、判断が難しい場合があります。チューブが不透明または乳白色すぎてはんだが見えない場合があり、接着剤 (ある場合) も目に見えて流れないことがあります。はんだが溶けたと思っても、冷却された接合部を引っ張ってテストすると、束の外側の表面だけがはんだに触れているため、電線が飛び出します。プレミアム コネクタは、冷却されるとより頑丈な仕上がりになる傾向があり、チューブが収縮してもひび割れが生じにくくなります。低品質のプラスチックは収縮後に脆くなる場合があり、冷却中に曲げると密閉が破れる可能性があります。つまり、プレミアム コネクタはユーザーフレンドリーに設計されています。インストール中に明確なフィードバック (視覚と触覚の両方) を提供し、冷却中に 1 秒余分に加熱したり、ワイヤがわずかに動いたりするなどの小さなミスを許容するほど頑丈です。低価格のコネクタでは、 「不足」と「過剰」の間の余地がはるかに少なくなります。経験豊富な 1 人のユーザーが、太いワイヤに安価なはんだスリーブを試した際に指摘したように、 「太いゲージのワイヤがヒート シンクとして機能し、はんだが溶ける前にプラスチックが溶け始めました」。これは、低価格の部品では理想的でない条件 (太いワイヤが熱を奪う) によってプロセス全体が台無しになる可能性がある一方で、高品質コネクタであれば、長時間の加熱でも破損しない強力な収縮チューブ材料を使用することでこのシナリオに対処できることを示しています。

まとめると、高品質のはんだ付けコネクタは、はんだ付けと収縮工程において予測可能性と耐久性に優れているため、設置プロセスを容易にします。また、考え抜かれた設計(適切な寸法、中心に配置されたはんだ、高い収縮率、透明なチューブ)により、ユーザーエラーの低減にも役立ちます。一方、安価なコネクタは、完璧な技術が求められることが多く、正しく接続できたと思っても、接続が不安定になることがあります。これらの熱収縮はんだ付けスプライスの使用経験があまりない場合でも、高品質の製品を使用することで成功率を大幅に向上させることができます。熟練したユーザーにとっても、時間と手戻りを節約できます。配線の設置はギャンブルのように感じるべきではありません。だからこそ、品質に少しお金をかけることは、長期的に見て大きな利益をもたらすのです。

👉 圧着工具を使わずに、Haisstronica のはんだ付けコネクタで堅牢性を確保します。

はんだ付け&シールワイヤコネクタの費用を高く設定すべきか、節約すべきか

品質と使いやすさの違いが明らかになった今、当然の疑問が湧いてくるでしょう。プレミアムコネクタは常に必要なのでしょうか、それとも安価なはんだシールコネクタで十分なのでしょうか?答えは、用途と接続の重要度によって異なります。では、どのような場合にハイエンドのはんだシールワイヤコネクタに投資するのが理にかなっているのか、そしてどのような場合に安価なオプションでコストを節約できるのか、詳しく見ていきましょう。

プレミアムコネクタに料金を支払うタイミング:

-

ミッションクリティカルまたは高リスクの接続:接続が重要なシステム(自動車の安全装置、エンジン センサー、トレーラーのブレーキ ライト、船舶のビルジ ポンプなどの配線、または故障すると安全上の問題や高額な損害につながる可能性のある回路) 内にある場合は、プレミアム コネクタを強く検討する必要があります。コストの差は、接続不良の潜在的な結果と比較するとわずかなものです。プレミアム ソルダー シール コネクタは、隠れた冷たいはんだや湿気の侵入によって偶発的に故障しない、強固な接合部を最も確実に提供します。専門のテスターが観察したように、優れたはんだシール (3M など) は「電線よりも強く、はんだ付け接続としてはほぼ同等」であるのに対し、安価な類似品は「電線をねじってテープで覆うのと大差ない」可能性があります。重要な配線では、見た目だけが安全なコネクタではなく、ストレス下での実証済みのパフォーマンスが求められます。品質が認められているブランド (場合によっては UL または MIL 仕様定格) に多少の費用を支払うことは、通常、ここで価値があります。 Haisstronica、3M、TE Connectivity(Raychem)などのブランドは品質の一貫性に定評がありますが、非ブランドのコネクタは同じキット内でも品質にばらつきがある場合があります。1つの接合部の不具合が致命的になったり、修理が困難な場合は、プレミアム製品を選びましょう。

-

過酷な環境(水、振動、熱):湿気、腐食性、または高振動の環境では、入手可能な最高の密閉コネクタ、あるいは全く別の方法が必要になります。高品質のはんだシールコネクタは、「マリングレード」または「オートモーティブグレード」として販売されることが多く、これらの条件に対応する材料(真の防水性を実現する二重接着リング、高温定格のチューブおよびはんだなど)が使用されています。例えば、マリングレードコネクタは、適切に設置されていればIP67/IP68の防水シール性能を謳う場合があります。ビルジ水にさらされる船舶の配線や、ボンネット下の車両の配線修理を行う場合は、その環境向けに設計されていると明記されているコネクタを購入するのが賢明です。安価なコネクタはパッケージに「防水」と記載されている場合もありますが、前述のように、実際には完全に密閉されなかったり、熱サイクルに耐えられなかったりするケースが多くあります。さらに、高振動エリア(エンジンや重機など)では、はんだ接合部が硬くなります。プレミアム コネクタは、より優れた張力緩和 (粘着力と柔軟なチューブの増加) によりこれを若干緩和する可能性がありますが、専門家からの一般的なルールは、一定の振動がある状態ではんだのみのスプライスを避けることです。このような場合は、別のソリューション (圧着収縮コネクタ) を選択するか、少なくとも最高級のはんだコネクタを使用してワイヤ ランを固定し、動きを最小限に抑えることができます。揺れる環境ではんだスリーブを使用してスプライスする必要がある場合は、プレミアム コネクタの優れた接続強度が、コネクタの緩み防止に最も効果的です。ある海洋配線の専門家が指摘したように、 ABYC (米国ボート アンド ヨット協議会) は、主に過熱または振動すると故障する可能性があるため、ボートではんだのみのバット コネクタを承認していません。それに沿って、一部の最高級コネクタには、クリティカルな用途ではんだに加えて圧着バンドが組み込まれています (これらのハイブリッド コネクタは非常に高価で、航空宇宙/軍事で使用されます)。ほとんどの人にとって、配線が厳しい環境にある場合、最高品質の防水はんだコネクタのみを検討する必要があります。その場合でも、圧着が望ましいかどうかを再確認してください。

-

専門職または大量生産:電気技師、自動車整備士、あるいは熱心なDIY愛好家で、数百もの接続作業を行う予定がある場合、プレミアムコネクタは手直し作業の削減により、長期的にはコスト削減につながります。接続の安定性が向上し(つまり、切断してやり直しが必要な不良接続箇所が少なくなる)、通常、箱から出した状態での不良率も低くなります。時は金なり。コネクタ1個あたりのコストは、接続が最初から正しく行われていれば、それだけの価値があります。また、クライアント向けの作業や、責任を伴う作業を行う場合は、高品質であることが証明されているコネクタを使用するのが賢明です。信頼できる部品を使用していることを示し、eBayで安物買いの銭失いではないことを示すことができます。一部のプレミアムコネクタには、UL認証、CSA認証などの認証が付いており、これは特定の業界の保険や規制遵守において重要となる場合があります。例えば、UL認証の熱収縮はんだ付けコネクタは、電圧と熱定格が検証されています。規格や基準に従って構築する場合は、それらの仕様を満たすコネクタを使用するしかない場合がありますが、通常、低価格のコネクタにはそのような仕様は含まれていません。要約すると、プロフェッショナル グレードの結果を得るには、プロフェッショナル グレードのコネクタに投資する必要があります。

-

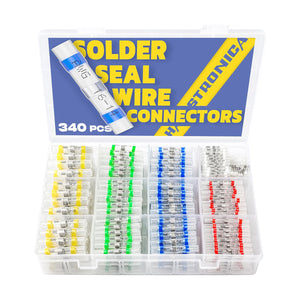

使いやすさが重要な場合:はんだ付けの経験があまりない場合や、完璧なセットアップがない場合は (狭い場所でワイヤを接合する場合や、風の吹く現場でワイヤを接合する場合など)、プレミアム コネクタが成功と失敗の違いを生む可能性があります。はんだが溶けて 1 回目の試行で正しく流れれば、少し余分に費やした金額は価値があるでしょう。ユーザー エラーに対するちょっとした保険を購入すると考えてください。さらに、プレミアム キットには、より詳しい説明書や、各サイズ用のコンパートメントが付いたケース、図表などの便利な追加機能が含まれていることが多く、全体的なユーザーエクスペリエンスとプロジェクトのビルド品質を向上させることができます。たとえば、 Haisstronica の180 ピースのはんだ付けコネクタ キット (AWG 26~10 をカバー) は、ラベル付きのオーガナイザー ボックスに入っており、色分けされたコネクタを使用しているため、各ワイヤに適切なサイズを簡単に選択できます。これは、ミスを防ぐのに役立つ小さな詳細です。また、高純度のはんだリングと高品質の接着剤を採用しており、前述のプレミアム機能の多くを、一部のトップブランド製品よりもはるかに安い価格で実現しています。(製品の詳細と価格については、 Haisstronica 180個入り熱収縮はんだシールワイヤーコネクタキットをご覧ください。)

👉 Haisstronica はんだ付けワイヤコネクタで作業を密閉し、IP 対応の保護を実現します。

予算コネクターで節約すべきタイミング(おそらく):

-

重要度の低い、屋内、または一時的な接続:屋内で簡単なガジェットやプロトタイプを製作する場合(例えば、机の下でLEDテープライトを繋いだり、おもちゃを修理したりするなど)、リスクは低くなります。このような場合、はんだ付けシールコネクタは便利な近道となり、安価なパックで済むかもしれません。環境は過酷ではありません(水や大きな温度変化はありません)。接続が失敗しても命に関わることはありません。大きな影響を受けずにやり直すことができます。安価なコネクタでも、はんだ付けされた接合部と基本的な絶縁性は確保できます。接続テストは必ず行ってください。安価なコネクタでも、取り付け後はしっかりと引っ張り、導通テストを行うことをお勧めします。最初に問題がなければ、軽い使用には問題ない可能性が高いでしょう。基本的に、趣味のプロジェクトや、簡単に監視したりやり直したりできる応急処置であれば、安価なコネクタで費用を節約するのは理にかなっています。多くの愛好家は、いじくり回したり学習したりするために、安価なパックを購入しています。ただし、期待しすぎないようにしましょう。不良品(はんだリングが外れたり、うまく溶けなかったりする)に遭遇する可能性があり、耐久性もプレミアムコネクタに劣る場合があります。接続状態は常に注意深く監視してください。

-

他の保護によって強化される場合:場合によっては、安価なコネクタしか持っていなくても、その信頼性を向上させたい場合は、追加の手順を実行できます。たとえば、安価な熱収縮はんだスリーブを使用した後、追加のシールとして、接続全体に高品質の接着剤付き熱収縮チューブの層を追加できます。これにより、コネクタ自体の弱い接着剤を補うことができます (実質的に、別の熱収縮ラップを使用したはんだ付け接合になります)。同様に、密閉性を高めるために、収縮させる前に安価なコネクタの両端に電気シーラントまたはシリコンを塗布することもできます。これらのトリックは完璧ではありませんが、安価なコネクタを使用してコストを節約しようとしている場合は、DIY で少し補強すると役立ちます。ただし、これを行うと時間とコストの差がいくらか解消されることに注意してください。そのため、最初からより優れたコネクタが入手できる場合は、それを使用する方がよいでしょう。それでも、すでに安価なコネクタをいくつか持っている人にとっては、それらを最大限に活用する方法です。冗長性を確保するため、または、負担や湿気から保護された場所でのみ、ペア(2 つのコネクタを交互に配置)で使用してください。

-

学習と練習:はんだ付けシールコネクタの使用が初めての場合は、廃材の電線で練習するため、安価なセットから始めるのも良いでしょう。そうすれば、過熱や重ね合わせ不足など、避けるべき落とし穴をすぐに理解できるでしょう。このシナリオでは、学習用なので、絶対的な品質は重要ではありません。コツをつかみ、適切にはんだ付けされ、密閉された接続がどのように見えるかを理解したら、実際のプロジェクトのために、より優れた製品にアップグレードできます。これは、本番の前に安価な材料ではんだ付けの練習をするようなものです。ただし、安価なコネクタは動作が異なる場合があり(例えば、溶けるのが早かったり、故障しやすかったりする)、高級品の完璧なトレーニング用アナログとは言えません。しかし、作業工程の大まかな感覚をつかむことはできます。ただし、最安品で悪い経験をしたからといって、すべてのはんだ付けシールコネクタを判断する必要はありません。高級品は、そうした多くの不満点を解消しているからこそ存在するのです。

いずれにせよ、「節約」して安価なコネクタを選ぶ場合は、リスクを十分に理解した上で判断してください。重要な配線には無名製品は避けてください。多くの専門家が、正体不明の安価なコネクタは完全なギャンブルになり得ると警告しています。予算が限られている場合は、少なくとも他のユーザーが適切だと評価している手頃な価格のブランドを探し、仕様(収縮率、接着剤の種類、または規格への準拠など)を確認してください。超安価なパックにはこれらの記載が一切ない場合が多く、これは危険信号です。信頼性の低いはんだスリーブを使用して誤った安心感を与えるよりも、従来の圧着コネクタと別途ヒートシュリンク(はんだ付け不要のコネクタ方式)を使用する方がよいでしょう。接続に失敗すると、電気火災(配線が緩んでショートした場合)から断続的な接続のトラブルシューティングに何時間もかかるなど、大きな問題が発生する可能性があることを忘れないでください。これらの結果が発生する可能性のあるシナリオでは、コネクタ1つあたり数セントの節約は価値がありません。

バランスの取れたアプローチ:必ずしも「全部かゼロか」というわけではありません。DIY愛好家の中には、コネクタを2種類用意している人もいます。必須の用途には高級セット、趣味ですぐに使える安価なセットです。ある専門家は、簡単な作業であれば基本的なコネクタで大きな違いは感じられないと述べていますが、「特殊なコネクタの中には安価なものを避けるべきものもあります…大手サプライヤーでも様々なグレードのコネクタがあります」。実際には、これは自分の判断で判断することを意味します。コネクタが乾燥した車内のダッシュボードの下に置かれる場合は、中価格帯または低価格のコネクタで十分でしょう。トレーラーヒッチの配線で風雨にさらされる場合は、入手可能な最高のコネクタ(または船舶用熱収縮チューブ付きの圧着コネクタ)を使用してください。そして、必ず正しく取り付けてください。最も高価なコネクタでも、十分に加熱しないと故障する可能性があります。また、非常に注意深く、条件が適切であれば、安価なコネクタでも問題なく機能します。

👉 耐久性に優れたHaisstronica ワイヤはんだ付けコネクタで回路を強化します。

結論 – プレミアムはんだシールコネクタは価値があるのでしょうか?

証拠を詳しく調べた結果、信頼性が高く長持ちする配線の修理や構築を重視するなら、プレミアム ソルダー シール コネクタへの投資は価値がある場合が多いという結論に至りました。プレミアム オプションは、優れた素材 (強力なソルダー接続と防水シュリンク シールを確保)、よりユーザー フレンドリな設計 (インストール エラーの削減)、テストで実証されたパフォーマンスによって他と一線を画しています。高品質のはんだ & シール コネクタを使用すると、従来の手作業によるはんだ付けジョイントに匹敵する強度と伝導性を持つ接合部が得られ、さらに熱収縮チューブのシーリングもすべて 1 つのステップで実現できます。安価なコネクタでも同じ利便性が約束されますが、前述のように、真の接続やシールを十分に実現できないことがよくあります。重要な用途や厳しい条件下では、低価格のコネクタでリスクを負う価値はありません。コストの差は比較的小さい (多くの場合、数セント/ドル) ですが、構築品質の差によって、電気接続が何年もの使用に耐えられるか、最悪のタイミングで腐食/故障するかが決まります。

とはいえ、普段使いや緊急性のない修理であれば、安価なはんだ付けコネクタにもそれなりの用途があります。特に、その限界を理解していればなおさらです。趣味のプロジェクトで問題なく使えて、問題が起こらないこともあるでしょう。しかし、自動車、船舶、あるいは産業用途など、厳しい試験を受けるような用途でこれらのコネクタを使用する場合は、専門家の間でもコストよりも品質を重視するべきだという意見が一致しています。ある独立した海洋関連の調査では、簡潔にこう述べられています。 「3Mのコネクタは電線よりも強度が高かった…一方、安価なコネクタは見た目は良いかもしれませんが、実際には電線をねじってテープで留める程度の性能しか持ち合わせていません。」 つまり、価格に見合った品質が得られます。Haisstronica( UL認証のソルダーシールコネクタを安定的に提供する)やオリジナルのミルスペックソルダースリーブなど、信頼のブランドによるプレミアムコネクタは、確実な接続を保証する安心感をもたらします。

結論として、はんだシールワイヤコネクタは適切に使用すれば素晴らしいツールです。ワイヤの接合を簡素化・高速化するだけでなく、きれいで防水性の高い仕上がりを実現します。「プレミアムバージョンは価値があるのか?」という質問への答えは、信頼性が求められるアプリケーションであれば、間違いなく「はい」です。プレミアムコネクタは、その優れた品質とユーザーエクスペリエンスによって、その価値を実感できるでしょう。安価なコネクタは、ちょっとした作業や些細な作業に取っておき、本当に必要な時にこそ高品質なものを使いましょう。プロジェクトのニーズに合わせてコネクタの品質を調整することで、常に安全で信頼性の高い電気接続を確保できます。

ユーザーフレンドリーなおすすめ

稼働時間が重要な場合は、精密な熱収縮はんだ付けが不可欠です。当社のはんだ付けコネクタ熱収縮チューブ内の合金と接着剤のバランスにより、完全な濡れと急速冷却を実現します。さまざまな電線サイズでも、コードに適合した安定した接合を実現するには、はんだ付け熱収縮チューブをお選びください。

👉 Haisstronica はんだ付けワイヤコネクタを使用して、プロ並みの結果を高速かつ繰り返し得ることができます。

出典: