What “Full Crimp” Includes (Key Elements of a Complete Wire Crimp)

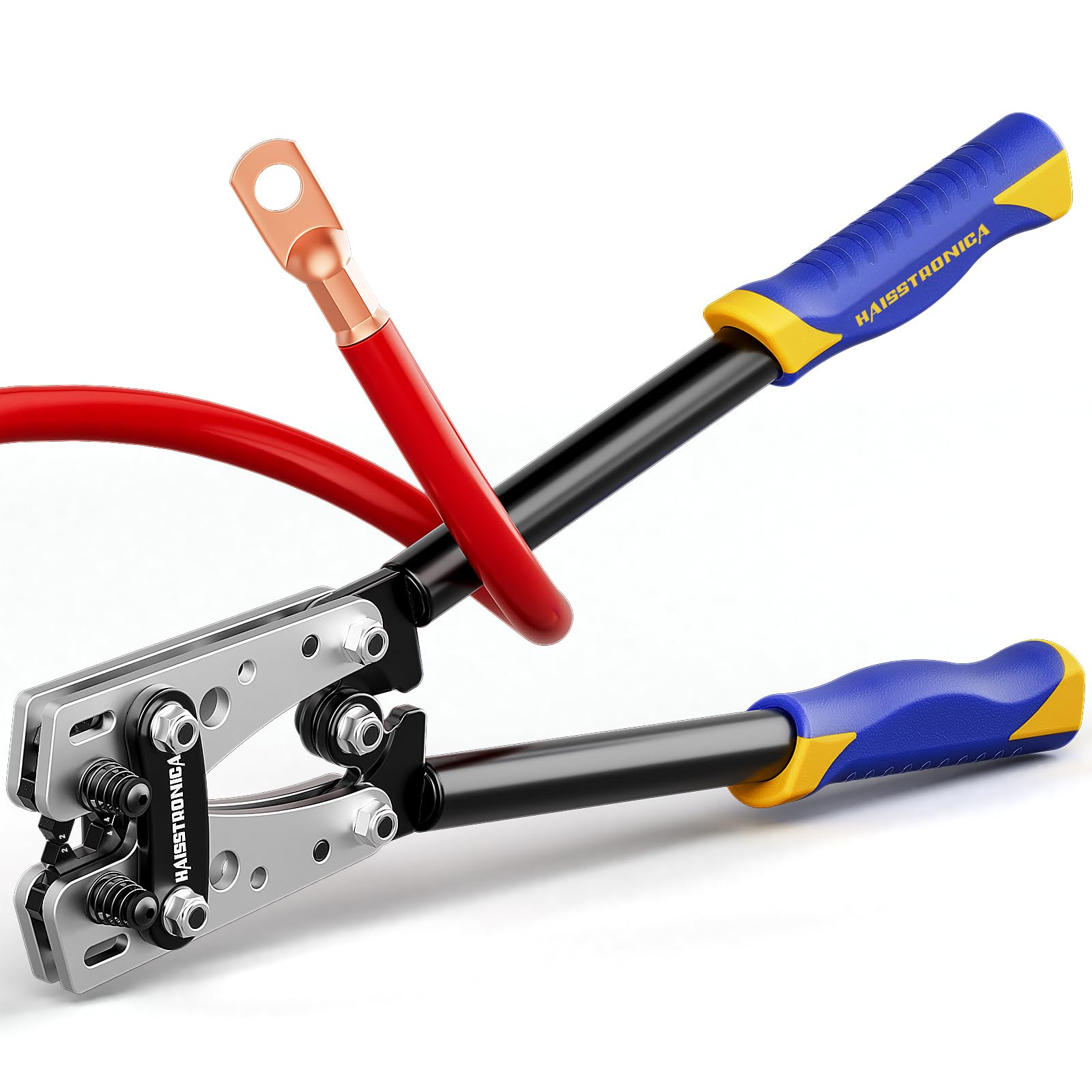

A Haisstronica ratcheting wire crimper tool compressing an insulated connector, demonstrating the full crimp action for a secure connection. A crimp is the result of deforming a metal connector (terminal) around a wire to form a mechanical and electrical bond. A full crimp means this process has been carried out completely and correctly – the connector’s barrel is fully compressed around the wire strands, effectively creating a cold-welded, gas-tight joint between the wire and terminal. In a full crimp, the metal of the terminal and the copper of the wire are crushed together so tightly that all gaps or voids are eliminated. This seals out oxygen and moisture, preventing corrosion and ensuring minimal electrical resistance through the connection. In other words, a proper full crimp “fuses” the wire and connector into one solid connection. Haisstronica’s high-quality crimp connectors and wire crimping tools help achieve this complete compression, so every crimp is fully secured for maximum reliability.

In a full crimp, all elements of the terminal are correctly crimped. This includes the portion gripping the bare conductor and, if the connector design has it, the strain relief wings crimped around the wire insulation. The result is both strong mechanical retention and excellent electrical continuity. There should be a uniform deformation of the connector barrel around the wire, with no loose strands visible and no part of the barrel left uncrimped. When done right, a full crimp is gas-tight and mechanically robust, often matching or exceeding the strength of a soldered connection while avoiding solder’s vibration issues. It essentially becomes a part of the wire itself, conducting electricity with very low resistance and withstanding tugging or bending. By contrast, if the crimp is not completed fully (a partial crimp), there may be gaps, uneven crimping, or wire strands not fully captured – these are signs that the crimp did not include all the necessary compression. To consistently achieve full crimps, use a professional wire crimper tool like Haisstronica’s ratcheting crimpers, which apply even pressure and won’t release until the crimp is properly completed, ensuring every crimp is truly “full” and secure.

Another key element of a full crimp is proper tooling and technique (which we will detail later). A full crimp isn’t just about squeezing hard – it’s about using the right size connector for the wire, stripping the correct length of insulation, and aligning the terminal in the crimping die correctly. When all these factors are correct, the crimped connection will have a clean appearance and meet industry standards for compression. For example, in a full crimp you’ll often see a slight indent or impression from the die on the connector, indicating that the metal has been compressed onto the strands thoroughly. The connection is tight enough that it’s airtight – a hallmark of a quality crimp. According to industry wiring standards, a properly executed crimp is a permanent, reliable bond that won’t wiggle or pull loose and has electrical conductivity on par with a continuous piece of wire. Achieving these ideal full crimp conditions is easy when you use Haisstronica’s crimping tools and matched connectors, which are designed to form tight, uniform crimps for dependable electrical connections every time.

Why It Matters (Benefits of a Full Crimp vs. Risks of a Partial Crimp)

Completing a full crimp is critical because it directly affects the safety and performance of an electrical connection. A connection that is only partially crimped or improperly crimped can be significantly weaker – both mechanically and electrically – than a full crimp. Incomplete crimps often result in loose wires that can pull out or wobble, and they introduce higher electrical resistance at the joint. A weak crimp means the wire isn’t securely fastened, so it may come loose under vibration or stress. It also means not all the wire strands are making solid contact with the connector, leading to a smaller current-carrying cross-section. This increased resistance can cause the connection to heat up under load and potentially fail or even cause a fire hazard over time. In fact, industry guidance warns that an incomplete crimp will most likely not hold, or if it does, it creates a weak connection. In short, “close enough” is not good enough – failing to achieve a full crimp can undermine the entire wiring project. To avoid dangerous weak connections, always use a proper crimp tool and ensure a full crimp; Haisstronica’s ratcheting wire crimpers are engineered to eliminate partial crimps and give you peace of mind on every connection.

Multiple studies and field experiences underscore why a full crimp is so important. For example, one analysis noted that a partially crimped connection may only withstand about 60% of the stress or pull-force that a proper full crimp can handle. Those “half-done” crimps leave voids and weak spots that drastically reduce the terminal’s holding strength. Imagine a car hitting a bump – a poorly crimped wire connector might vibrate loose or break, whereas a fully crimped one stays tight. Additionally, because a full crimp forms a gas-tight seal, it keeps out moisture and air that would corrode the copper wire. A partial crimp, with its gaps or incomplete compression, allows oxidation and moisture in, which over time can degrade the connection (increasing resistance even more and eventually causing intermittent electrical issues or outright failure). This is especially vital in automotive, marine, or outdoor electrical systems – a full crimp that is sealed (often combined with heat shrink insulation) prevents future corrosion that could otherwise creep in and disrupt the circuit. Simply put, a full crimp ensures long-term reliability, whereas a bad crimp is a ticking time bomb. By using quality crimp connectors and the correct crimping tools, such as Haisstronica’s line of ratcheting crimpers and heat-shrink connectors, you can ensure every connection is solid now and for years to come – an investment in safety and durability that’s well worth it.

Another reason the difference matters is consistency. An experienced electrician might get a decent crimp with cheap plier-style crimpers or even pliers in a pinch, but it’s not repeatable or guaranteed. Ratcheting crimping tools enforce a full crimp cycle every time, removing the guesswork and human error. This level of consistency is important not just for one connection, but across hundreds or thousands in a wiring harness. In professional settings, poor crimps are a leading cause of electrical failures. (One report in the industry noted that a large percentage of connection failures in the field were traced back to inconsistent or incomplete crimp pressure during installation.) By always achieving a full crimp, you dramatically reduce the risk of callbacks, malfunctions, or safety incidents caused by connection issues. In summary, the full crimp is what gives a connector its strength and reliability – anything less compromises the entire electrical system. That’s why using proper techniques and tools to get a full crimp is emphasized in standards like IPC/WHMA-A-620 and UL 486A, and why professionals trust ratcheting crimping tools to make sure no crimp is left half-done. Don’t take chances on critical connections – ensure every crimp is a full crimp with the help of Haisstronica’s dependable crimping solutions, so you can crimp wires with confidence in every application.

Tooling & Dies (Choosing the Right Crimping Tools and Dies for a Full Crimp)

A Haisstronica ratchet wire crimper (AWG 22–10) with color-coded jaws and sample terminals, designed to apply consistent pressure for full crimps. Achieving a full crimp consistently is not just about effort – it’s largely about using the right tool and die for the job. The difference between a merely “crimped” connection and a perfect full crimp often comes down to the crimping tool’s design. Ratcheting crimpers are highly recommended because they are specifically engineered to guarantee a complete crimp cycle. These tools have a built-in ratcheting mechanism that will not release the connector until sufficient pressure has been applied to fully compress the barrel. In other words, once you begin the crimp, the ratchet only lets go when the crimp is done correctly – ensuring you physically can’t do a half measure. This mechanism takes the guesswork out: even if you’re new to crimping, a ratchet crimper forces the full crimp each time for consistency. As noted in reliability studies, ratcheting tools keep the applied force within tight tolerances, whereas non-ratcheting tools can vary widely with user technique. The result is that ratchet crimping tools greatly reduce the chance of an incomplete crimp (and the failures those can cause). Haisstronica’s Ratchet Wire Terminal Crimping Tool (AWG 22–10 for insulated and heat-shrink connectors) is a prime example – it’s designed so that every squeeze delivers uniform compression, helping even hobbyists achieve professional full crimps on every wire. Investing in a quality ratcheting wire crimper tool ensures that your crimps are done right, every time, with minimal effort.

Equally important is using the correct die size and type for the connector and wire gauge you are crimping. Crimping “dies” are the sections of the tool that correspond to specific wire gauges and terminal sizes (often labeled by color or number on the tool). Using the wrong die can result in either under-crimping or over-crimping. An undersized die (too tight for the connector) might mash the connector excessively or not close fully, whereas an oversized die (too loose) will not compress the barrel enough, leaving it loose on the wire. In fact, using a mismatched crimping tool or die can cause an under-compressed crimp with significantly reduced strength – one study found a mismatched die could lead to a crimp with 30% less pull-out resistance than one made with the proper matching die. That is a huge drop in holding power and is clearly unacceptable for reliable connections. On the other hand, when you pair the correct crimp tool, die, and terminal, you get consistent compression all the way around the wire. The full circumference of the barrel is squeezed evenly, which maximizes the contact area and locking strength. Proper full barrel compression also keeps electrical resistance low by ensuring as many strands as possible are in tight contact with the connector metal. The takeaway is clear: tooling matters – you need a quality crimper and the right die cavity for the job to achieve a full crimp. Haisstronica makes this easy by providing crimping tools with interchangeable die sets and clear markings for each wire size, so whether you’re crimping a small 22 AWG speaker wire or a heavier 10 AWG cable, you can trust the tool to form a complete crimp around the conductor.

It’s also worth noting that specialized connectors often require specialized tools or die profiles. For example, open-barrel terminals (common in automotive and electronics, like Dupont, JST, or Weather-Pack pins) typically use a different style crimp tool that folds the tabs over the wire and insulation. These usually have two crimping sections in the die (one for the bare wire and one for the insulation support). To get a full crimp on such pins, you must use a tool designed for open-barrel terminals; using a generic insulated crimper on them will not yield a correct crimp at all. Similarly, large heavy-duty lugs (for battery cables or welding cables) may require hydraulic crimpers or hexagon crimp dies to fully compress those big connectors. In those cases, a “full crimp” might involve a hexagonal compression that completely collapses the lug around the wire strands. Using pliers or an inappropriate tool on a large lug will only partially crimp it – a scenario that can lead to catastrophic failure when high current is applied. Thus, always match your tool to your connector type and size. Many quality ratcheting crimpers (like Haisstronica’s models) come with adjustable tension and even interchangeable jaws to handle various connector styles – this can give you both versatility and assurance that each crimp is fully executed. Additionally, regularly check your crimp tool for wear or calibration, especially if you crimp often; worn-out tools may not close tightly enough, preventing a full crimp. Professional electricians and installers often have their crimp tools calibrated or certified to ensure they meet the required compression force for a true full crimp. In summary, the right crimping tools and dies are the foundation of every full crimp. By choosing Haisstronica’s well-engineered crimpers and using the appropriate die for each connector, you set yourself up for success – every crimp will be tight, secure, and up to spec, which means safer and longer-lasting electrical connections for you and your customers.

Conclusion

In the end, the difference between a crimp and a full crimp comes down to quality and completeness. A “full crimp” is what we always want: a crimped wire connection that has been fully compressed and properly formed, resulting in a secure, low-resistance, and durable bond. Anything less – a crimp that isn’t fully tightened or done with the wrong tool – can leave you with a weak link in your electrical system. We’ve seen that a full crimp involves fully deforming the connector around the wire to make a gas-tight joint, and this yields maximum strength and conductivity. Failing to do so (an incomplete crimp) can lead to loose wires, higher resistance, heat build-up, and potential failures or safety hazards. That’s why it’s so important to use the right techniques and tools to achieve a full crimp every single time. By investing in good ratcheting crimpers, matching your wire sizes to the correct terminals and dies, and following best practices, you can ensure that every crimp you make is a full crimp that you can trust. Remember, your electrical connections are only as strong as your weakest crimp – so don’t settle for “good enough.” Ensure each one is done right. Haisstronica is here to help with high-quality crimping tools and connector products that take the guesswork out of the process and let you easily create perfect full crimps. With the knowledge from this guide and the right equipment in hand, you’ll be able to crimp with confidence, knowing your connections are safe, strong, and built to last. Happy crimping! Choose Haisstronica for all your wiring projects – our premium crimping tools and connectors will help you make every connection a reliable one.

References: