Modern solder seal connectors – also known as heat shrink solder connectors, solder sleeves, or solder-and-seal wire connectors – have become popular for DIY wiring repairs and custom projects. They combine a low-melting solder ring and adhesive-lined heat shrink tubing to create a quick electrical splice that is both soldered and sealed in one step. These connectors are widely marketed as “waterproof” solutions for splicing wires, often used in automotive and marine applications where moisture is a concern. But how waterproof are they really? Before you buy a wire connector solder kit and expect a magic bullet, it’s important to understand how these connectors work and what their realistic capabilities are in the real world.

Solder vs. Crimp – a brief context: In the world of electrical wiring, there’s a long-running crimp vs. solder debate. Crimp connectors (a type of solderless wire connectors) use mechanical compression to join wires and are the gold standard in many automotive and marine OEM applications. Soldered connections, on the other hand, chemically bond wires with melted metal. The solder-seal connector essentially tries to offer the best of both – a solder splice connection that is also insulated and sealed like a crimp-and-heat-shrink combo. These solder and heat shrink connectors are marketed to DIYers as an easy alternative to using a soldering iron (or a crimp tool) and separate heat shrink tubing. Instead of learning how to solder a wire to a connector manually, you simply slide the self-soldering connector on, twist the wires together, and heat it with a heat gun. The result is a soldered wire connection with a shrink-wrapped, adhesive-lined seal. It sounds great in theory – a quick solder stick connector that anyone can use – but to set realistic expectations we need to dive deeper into how the seal is made, what waterproof really means versus water-resistant, and where these connectors work well versus where they don’t.

Before going further, note that solder-seal connectors go by many names. You might see them advertised as wire solder connectors, solder seal wire connectors, heat shrink solder butt connectors, solder & seal connectors, solder sleeves, heat shrink solder splices or even by brand-specific terms like “solderstick connectors.” Despite the different names, they all refer to the same concept: a transparent heat-shrink tube with an internal ring of low-temperature solder (usually with flux) and often two rings of thermoplastic adhesive (one near each end). In this article, we’ll use terms like solder-seal connectors, heat shrink solder connectors, and solder sleeve connectors interchangeably for convenience. Now, let’s break down how these connectors are built and how they actually achieve an environmental seal.

👉 Choose Haisstronica wire solder connectors for clean, compact joins.

How the Seal Is Made (The Anatomy of a Solder-Seal Wire Connector)

To understand the waterproofing claims, we first need to look at how these connectors are constructed and used. A typical solder-seal wire connector (often sold in assorted automotive wire connector kits) consists of:

-

Heat Shrink Tubing: a transparent polyolefin tube that shrinks in diameter when heated. It’s usually adhesive-lined heat shrink, meaning there’s a coating of hot-melt glue inside the tube.

-

Solder Ring (Solder Preform): a band of low-temperature solder alloy in the middle of the tube. This solder often contains a rosin flux core to help it flow. The solder ring is positioned at the center so that when two stripped wire ends are inserted from each side, they overlap right under this ring.

-

Adhesive Sealant Rings: on one or both sides of the solder, there are usually colored bands of thermoplastic adhesive. When heated, these solder connector sealant rings melt and bond to the wire insulation, sealing out water and providing strain relief.

The installation process is straightforward: You strip the insulation off the two wires you plan to splice (typically about 1/4 inch to 1/2 inch, depending on connector size), twist the exposed wire ends together or lay them overlapping inside the connector, then apply heat (usually with a heat gun). The tubing will shrink down, the solder ring will melt and flow into the wire strands, and the adhesive will liquefy and seal the connection as it cools. In a successful installation, the solder forms a solid electrical wire splice solder bond, and you’ll often see a bit of adhesive ooze out at the ends of the tubing – a sign that you’ve achieved a full seal. The result is a soldered butt splice that is insulated and potentially waterproof.

The key to the “seal” is that the adhesive glue lines should bond to the wire’s insulation on each side, closing off any gaps where moisture could enter. Internally, the soldered joint itself is encapsulated by the tube, theoretically protected from air and water. In essence, the connector creates a mini environment around the joined wires – much like a solder and shrink tube encapsulation.

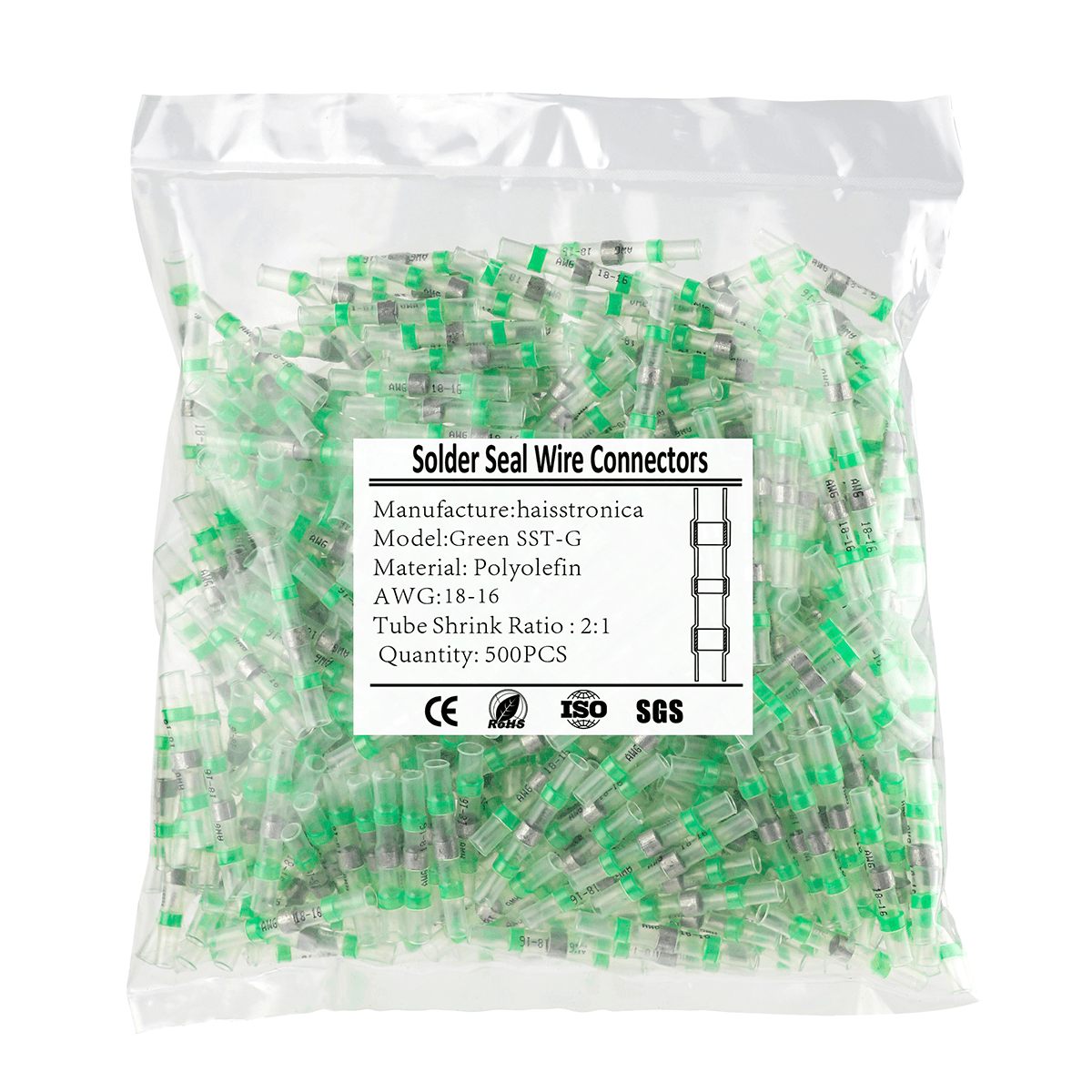

Materials and design matter: Not all solder-seal connectors are equal. Quality brands use good tubing with higher shrink ratios and strong adhesive. For example, a premium connector might have a 3:1 or 4:1 shrink ratio tubing that can tightly conform to wires of various gauges, ensuring a snug fit and wire sealant action on irregular surfaces. Lower-end connectors often use 2:1 shrink tubing, which can still work but offers less compression, potentially leaving voids if the wire insulation is thin. The solder alloy is also crucial – many connectors use a low-melting-point eutectic alloy (commonly Sn42/Bi58) that melts around 138 °C (280 °F). This allows the solder to liquefy under a heat gun without needing the higher temperatures of a soldering iron, and without charring the tubing. The downside of this low-temp solder is its lower melting point: if the connection later experiences high heat (near the solder’s melting range), the joint could theoretically re-melt or weaken – we’ll discuss that risk later.

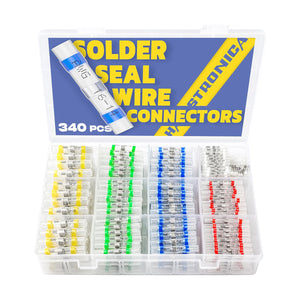

Sizing and color codes: Solder-seal connectors typically come color-coded by size (just like crimp butt connectors). Red, blue, yellow, white are common colors indicating different wire gauge ranges (for instance, blue solder connectors are often for 16–14 AWG mid-size wires, red for 22–18 AWG, yellow for 12–10 AWG, etc.). A good solder wire connector kit will include all sizes. For example, Haisstronica offers a 180PCS Heat Shrink Solder Seal Wire Connectors Kit (AWG 26–10) that covers the most common wire sizes in automotive and marine use. Each connector size has an optimal range of wire diameters it can seal; using the correct size is important to ensure the adhesive properly melts and grips the wire insulation.

When properly installed, a solder-seal connector yields a shiny, solid solder joint inside and a fully shrunk tube with adhesive visible at the ends. This gives a strong electrical connection and a degree of mechanical strain relief and environmental protection. In fact, when done correctly, the tensile strength of a good solder-seal splice can be very high – one test by Practical Sailor found that premium heat-seal connectors (3M’s product in this case) held with strength exceeding the wire itself, meaning the wire would break before the splice did. That indicates a well-made soldered connection and good adhesion of the tubing. However, cheaper no-name connectors in the same test performed poorly, in some cases the solder barely bonded and the splice pulled apart easily, offering no more strength than a simple taped twist of wires. This huge quality variance is why experts advise sticking to reputable brands (or at least testing a sample of your connectors) rather than trusting bargain-bin products.

So, how is the “waterproof” seal made? It’s essentially through the combination of melted solder fusing the conductors and melted adhesive gluing the insulation. This creates a closed system around the join. But whether this is truly waterproof depends on conditions – which leads us to the next section.

👉 Improve signal with Haisstronica wire connector solder—airtight protection.

Waterproof vs. Water-Resistant in the Real World (What It Means for Solder-Seal Connectors)

One of the biggest selling points of these connectors is that they are “waterproof”. In reality, we should differentiate between waterproof and water-resistant, and consider what those terms mean for an actual wire splice in use. According to industry usage, waterproofing means preventing moisture ingress completely, whereas water resistance implies it can tolerate some exposure but not necessarily total immersion or indefinite exposure. So, where do solder-seal connectors stand?

Marketing claims – IP67 ratings: Many solder-seal connector kits advertise an IP67 water-resistance rating. IP67 (Ingress Protection rating) is a standard that means the item can withstand being submerged in up to 1 meter of water for up to 30 minutes. For instance, one product description states that after heat shrinking, solder seal wire connectors come with an IP67 water-resistant rating, preventing water from entering the connector. In practical terms, IP67 water resistance indicates that if you briefly drop your connected wires in shallow water or expose them to rain or splashes, the connection should remain dry inside. However, IP67 does not mean the connection can be kept underwater indefinitely. As the SolderStick company notes, IP67 protects against immersion between 15 cm and 1 m for ~30 minutes – longer or deeper exposures could still cause leakage. In short, these are water-resistant wire connectors, very useful for wet environments, but they aren’t magic capsules that permanently keep water out under all conditions.

Real-world conditions vs ratings: Consider how these might be used in automotive or marine settings. In an automobile, you might have solder-seal splices in the wiring for trailer lights or backup cameras – places that get splashed with water from the road. In a boat, you might use them for fish-finder or bilge pump wires where humidity and the occasional splash (or even brief submersion) is possible. In outdoor landscape lighting, these splices might be buried a few inches underground or exposed to rain. In all these cases, a well-made solder-seal connection can keep moisture out effectively – for a while and under moderate exposure. The dual adhesive rings, if properly melted and bonded, will prevent water from seeping directly into the joint or condensing inside the tube. Many users report success with such connectors surviving seasons of rain or occasional dunking without issue.

However, problems can arise when conditions exceed the connector’s sealing capability or when installation is imperfect. One known issue is water ingress via the wires themselves. Even if the tubing is fully sealed at the ends, the copper strands of the wire can act like a wick. Capillary action can draw water in along the inside of the insulation if any part of the wire (beyond the sealed zone) is exposed to water. As a member of the Blue Robotics community pointed out, “Water can travel between wire strands or between wires and the insulation. Glue-lined heatshrink would let water pass over the solder connection from under the insulation of one wire and continue into the next wire. The glue is unlikely to form a perfect seal around the solder connection.”. In other words, unless the adhesive truly bonds to every strand and crevice, a microscopic pathway might let water creep along the wire into the joint over time – especially under pressure or long-term submersion. This is why simply labeling these connectors “waterproof” can be misleading for continuous or extreme exposure.

Water-resistant, yes; permanently waterproof, not exactly: Given the above, it’s safer to consider solder-seal connectors as water-resistant splices. They will protect against moisture far better than an open splice or standard (non-sealed) crimp connector. For instance, after heating, the melted adhesive forms a barrier and water will bead off the shrunk tube rather than penetrate. In a controlled test scenario, a properly installed connector can achieve a seal good enough to dunk in water for minutes with no ingress. But in a real-world scenario like an underwater cable or a bilge pump wire sitting in water 24/7, eventually some moisture could find its way in, or the seal could be compromised due to temperature cycling, strain, or degradation of the adhesive.

For critical waterproofing needs (say you need a connection to stay dry underwater indefinitely), professionals often take extra measures. There are tricks such as double-sealing (sliding an extra larger heat shrink tube with adhesive over the first one), or potting the connection in epoxy or silicone before shrinking the tube. In fact, one experienced Navy technician shared a method to make splices good to 1000-foot depths by filling heat shrink tubing with silicone sealant before shrinking, forcing the silicone to squeeze out and fill any voids. This is not part of typical solder-seal connector instructions, but it shows what’s needed for extreme waterproofing beyond the connector’s inherent ability.

Temperature and environment effects: Another aspect of “real world” waterproof performance is temperature changes. A splice in an engine bay, for example, might see heating and cooling cycles that cause the materials to expand and contract. The seal could potentially develop micro-gaps over time in such scenarios. Also, the adhesives used in most connectors (often EVA-based hot melt) have operating temperature limits (commonly up to ~125 °C). If that is exceeded, the adhesive might lose integrity. Similarly, chemicals like gasoline, oils, or solvents can sometimes attack the adhesive or tubing if the connectors are not specifically rated for it. So for marine/outdoor use in harsh chemical environments, one should look for marine grade solder connectors that explicitly mention resistance to fuels or salt (some products use special polyamide adhesives for this).

Bottom line: Solder-seal connectors offer a convenient way to get a sealed solder connection that is highly water-resistant for most practical purposes. They will keep out rain, splashes, and short-term submersion to a reasonable degree – a properly melted connector even meets IP67 in many cases. But you should not assume that a simple heat shrink solder connector is equivalent to a potting compound or a fully waterproof enclosure. Treat them as weatherproof or water-resistant connectors. If your application involves continuous exposure to water (especially saltwater) or being submerged deeper or longer than the IP67 envelope (e.g., underwater lighting wiring, transom-mounted sensors, etc.), you should consider additional waterproofing steps or different connection solutions. Manufacturers themselves often advise using connectors that specifically claim higher IP ratings (like IP68) for such situations – and even then, proper installation is crucial.

In summary, waterproof vs. water-resistant for these connectors boils down to usage: For normal automotive, marine, and outdoor wiring that might get wet or even temporarily dunked, solder-seal connectors will hold up well and keep connections dry. But for extreme conditions (constant submersion, high pressure, or critical circuits where any moisture could be disastrous), don’t rely solely on a heat shrink solder sleeve. Either upgrade to fully waterproof connection systems or reinforce the solder-seal with additional sealing measures. Remember the saying: Water-resistant is not the same as waterproof.

👉 Streamline installs with Haisstronica soldering connectors—heat-activate and go.

Where They Work vs. Where They Don’t (Best Uses and Limitations of Solder & Seal Connectors)

By now, it’s clear that solder-seal connectors have specific strengths and weaknesses. Let’s break down where they work well and where they are not recommended. Having realistic expectations means deploying these connectors in scenarios that play to their advantages and avoiding or at least being cautious in scenarios that expose their flaws.

Where Solder-Seal Connectors Work Well:

-

Automotive Wiring (Non-Critical Circuits): In cars, trucks, or motorcycles, heat shrink solder connectors are great for accessory wiring, lighting, and audio installs. For example, splicing an LED light bar wire or repairing a broken speaker wire in the door – a solder-seal splice here provides a solid electrical connection and protection against moisture and road grime. These connectors are especially handy for automotive DIY enthusiasts who may not have expensive crimp tools; a simple heat gun (or even a butane micro-torch used carefully) can do the job. As long as the splice isn’t in a spot with constant engine vibration or extreme heat, it should last. Many users in car forums report success using solder-seal connectors for aftermarket electronics and trailer hitch wiring, noting the convenience of not having to use a soldering iron under the car. The soldered joint inside means low resistance and good conductivity, and the sealed exterior prevents corrosion in the splice over time.

-

Marine and Boating Applications (Above Deck or Protected Areas): On boats, sealed solder connectors can be useful for wiring that needs to be moisture-resistant – for instance, connecting LED strip lights in a cabin, wiring up a fish finder, or splicing bilge pump float switch wires located above the waterline. The marine environment is harsh (saltwater, humidity), so having a sealed connector helps a lot to prevent corrosion. When using solder-seal connectors in marine settings, it’s wise to choose marine-grade ones that mention compliance with marine standards or use tinned copper wiring. While crimp and seal connectors (crimp butt connectors with adhesive heat shrink) are traditionally preferred by marine professionals, a well-made solder-seal connection on a small gauge wire can perform similarly in these contexts. Just ensure the wire is supported (strain relieved) so it’s not flexing at the joint too much with the boat’s motion.

-

Outdoor & Off-Road Electronics: If you’re wiring up outdoor landscape lights, an irrigation system valve, a solar panel array, or off-road vehicle accessories (like ATV winches or fog lights), solder-seal connectors can offer a quick solder solution that stands up to dirt and moisture. They are commonly used in off-road and remote installations because you only need a compact kit of self-soldering wire connectors and a heat source to make reliable splices on the go. For example, overland enthusiasts might carry a pack of these in their repair kit for trail fixes – if a wire snaps on your 4x4’s lighting harness, you can strip it and heat shrink solder it back together with a lighter or heat gun, getting a decent sealed repair without lugging a soldering iron and generator. The versatility of not needing an electrical power tool makes them very practical outside the workshop.

-

General DIY Electrical Projects: Beyond vehicular use, think of any project where you need to join wires and protect them: RC hobby wiring, drones, garden pumps, LED strips, etc. For moderate current connections (typically these connectors handle from very fine wire up to about 10-12 AWG max), they simplify the process. As long as you’re within the connectors’ ratings (they are not meant for high amperage mains power or anything above their gauge limit), you get a connection that is about as good as a hand-soldered joint, sealed against the environment, with minimal skill required. Many kits come with a wire connectors solder assortment, allowing you to tackle a range of small wiring jobs easily.

-

When Speed and Convenience Matter: If time is of the essence or you don’t have the right crimp lugs, these connectors shine. For field repairs or when you’re away from a full tool set, a quick solder connector can save the day. They eliminate the need for carrying separate solder and shrink supplies (no need for flux, solder wire, shrink tubes, etc., everything is built-in). For one-off repairs or prototyping, this convenience often outweighs any minor differences in ultimate strength or perfection. It’s also easier to visually inspect than a taped splice; you can see the solder has melted and the tubing has shrunk clear around the wire. In short, they work well when you need a fast, decent-quality splice with moisture protection.

👉 Rely on a Haisstronica solder connector for secure, sealed terminations.

Where Solder-Seal Connectors Don’t Work (or Require Caution):

-

High Vibration Environments: One of the biggest downsides of soldered connections is that they can create a stiff section in the wire, which is prone to fatigue failure under vibration. In automotive engine bays or on vehicles like marine engines, vibration can flex the wire right at the ends of the solder joint. Over time, this can cause the wire to break where the flexible copper strands meet the hardened soldered part (a classic stress riser problem). Automotive manufacturers generally avoid solder-only splices in harnesses for this reason – they prefer crimps, which leave the wire strands more flexible. As an expert from Haltech (an automotive electronics company) notes, cracking of solder joints in wiring harnesses is not uncommon after years of service, due to mechanical stress and vibration, even if initially protected with heat shrink. So, where not to use solder-seal connectors? Avoid them in areas with continuous or heavy vibration: e.g. near engine blocks, on motorcycles near the engine, on outboard motors, or any wire that’s continually moving/bending (trailer towing harness that flexes, robot arms, etc.). A solderless connector (quality crimp) or a soldered joint that’s additionally strain-relieved might be better in such cases. If you must use a solder-seal in a vibrating area, secure the wire on both sides of the splice so it doesn’t wiggle.

-

High Temperature Zones: Recall that many solder-seal connectors use a low-temp solder (melting ~138 °C) and heat-activated glue. In locations that routinely get very hot, there’s a risk the solder could soften or the glue could degrade. For example, under the hood of a car near the exhaust manifold or turbo, temperatures can climb significantly. In such spots, even a sealed connector might fail. Many OEM standards explicitly caution against solder splices in high-heat zones. The ABYC (American Boat and Yacht Council) guidelines similarly warn that if a soldered connection is overheated (such as an overloaded circuit heating the wire), the solder can re-melt and the heat shrink can soften, potentially letting the joint pull apart and cause a short. Thus, don’t use solder-seal connectors in environments above their rated temperature (often around 125 °C for automotive-grade ones). Stick to those areas where ambient temps stay reasonable.

-

Critical or Regulated Connections: In certain industries and applications, solder-seal butt connectors are actually not allowed or not trusted. For instance, marine wiring standards (ABYC) forbid solder as the sole means of connection – any connection must have a mechanical crimp or screw plus optionally solder, but not solder alone. Because a solder-seal connector relies only on the solder for mechanical connection (there’s no crimp barrel), it doesn’t meet that requirement. If you’re working on a boat that needs to adhere to ABYC standards or on aircraft/aerospace wiring (which have their own stringent rules), you should avoid these connectors. The same goes for life-safety or mission-critical circuits (airbag wiring, critical sensors, medical devices, etc.) – such cases typically call for proven crimped or welded connections, and sometimes redundancy. Even if you’re just a DIYer, it’s wise to not use solder-seal connectors for critical engine control wires or safety devices in a car; a failure there could be catastrophic. Use them in less critical parts of the circuit and use more failsafe connection methods for crucial links.

-

Continuous Water Exposure or Submersion: As discussed in the previous section, if a connection will be underwater continuously or exposed to heavy water spray constantly, a simple solder-seal connector by itself might not hold up forever. For example, wiring for an underwater pool light, or a boat trailer’s submersible lights that go into the lake every weekend – these are cases where even a “waterproof” connector can eventually let water in. The connector’s sealant is not equivalent to a fully potted connection. In such cases, either use specialized waterproof connectors (gel-filled capsules, IP68 rated cable joints, etc.) or add extra sealing (like epoxy potting over the solder seal). The solder-seal product is great for water-resistant wire splices, but for underwater splices that must last years, it’s often the wrong tool. Additionally, extreme cold can also be a concern because freeze/thaw cycles could potentially suck moisture in or crack the seal – although this is less documented, it’s something to keep in mind for outdoor winter conditions.

-

Large Gauge or High Current Cables: Solder-seal connectors are typically available only up to a certain size (usually for wires up to AWG 10 or 8 at most). They are not meant for very heavy gauge battery cables or high-current feeder wires. For those, crimped lugs or other more robust connectors are the norm. Furthermore, high current through a soldered joint can sometimes heat that joint significantly (if there’s any resistance), which again risks melting the low-temp solder. For example, you wouldn’t use a solder-seal connector on a car’s starter cable or alternator cable – those carry too much current and any slight imperfection in the solder joint could heat up. Those applications require a proper crimped and usually bolted connection. So for wire connections that carry a lot of amperage, stick to purpose-built crimp connectors or fused connectors; solder-seals are intended for moderate currents and smaller wires.

-

Situations Requiring Inspection or Re-entry: If you anticipate needing to disconnect the splice or regularly inspect it, solder-seal connectors are not ideal. They create a permanent bond (in fact, people often ask “how do I remove solder seal wire connectors?” – the answer is basically you have to cut it out and re-splice or try to re-melt and pull apart, which isn’t clean). So for temporary or test connections, use connectors that can be easily undone (like screw terminals, bullet connectors, etc.). Also, because the solder and wires are hidden inside the opaque solder ring and glue, it’s hard to 100% visually verify the quality of the splice without destructive testing. Professionals can usually tell by the signs (clear tubing shrunk, solder fillet visible, adhesive extruded), but a novice might not spot a cold solder joint inside. This lack of easy inspection is another reason some are wary of relying on these in critical spots – you can’t verify the joint integrity without pulling it apart. With a crimp, at least you can sometimes tug-test each one; with solder-seal, a bad joint might look okay until it corrodes or pops off later.

To sum up this section, use solder-seal connectors for what they’re good at – quick, convenient, moderately strong and sealed splices in low-to-medium stress environments. Avoid or think twice about them when vibration is high, temperatures are high, regulations forbid solder-only, constant water or critical reliability is at stake, or the wires are too large for them. In those latter cases, you’re usually better off with a high-quality crimp connector (and you can always add adhesive-lined heat shrink over a crimp – essentially making your own “crimp and seal” connector). Even the strongest advocates of solder-seal connectors acknowledge that it’s about the right application: “Use them where the environment suits them” as one guide puts it – otherwise, use other methods.

👉 Lock in continuity with a Haisstronica soldered connector—set it and forget it.

Conclusion: Setting Realistic Expectations for Solder-Seal Wire Connectors

Solder-seal wire connectors are a clever hybrid invention that have earned their place in the toolkit of hobbyists, mechanics, and even some professionals. They simplify the process of making a soldered, sealed electrical connection by combining it all in one piece – a sort of “just add heat” solution. When you buy these connectors (such as a Haisstronica or 3M solder seal connector kit), you should have realistic expectations about what they can and cannot do:

-

They provide a strong electrical bond and good protection: A correctly installed solder-seal splice can be as electrically sound as a hand-soldered joint and as sealed as a dedicated waterproof connector. They effectively keep out moisture in typical automotive/marine/off-road environments, preventing corrosion at the joint. Many users find their heat shrink solder splices last for years in dashboards, engine compartments (away from direct engine heat), boat cabins, and outdoor gear. In terms of conductivity and pull strength, quality connectors perform excellently – in tests, the best solder-seal connectors matched the strength of traditional crimps and solders.

-

“Waterproof” is not absolute: These connectors should really be thought of as water-resistant solder connectors. Yes, they can survive water splashes, rainstorms, and short-term submersion (IP67 type scenarios), but you shouldn’t rely on them for permanent underwater cables or in place of proper sealed bulkhead connectors. If your wiring will be exposed to the elements constantly, make sure to use high-quality solder-seal connectors (avoid the cheapest no-name versions which may fail to seal or have poor solder) and consider additional protective steps. Always inspect that the adhesive has melted and flowed out, indicating a good seal. And if possible, position the splice where it’s not sitting in water continuously.

-

They are not a one-size-fits-all replacement for crimping or traditional soldering: There’s a reason that in critical applications, solderless connectors like crimps are still king – reliability under stress. Crimp vs solder doesn’t have a universal winner; each has its use. In 90% of standard wiring harness cases, experts lean toward crimp connections for best long-term results, especially in vehicles. But that leaves a niche where solder-seal connectors are “good enough” and extremely handy. The trick is knowing the difference. If you’re fixing trailer wires on the fly or adding some fog lights, solder-seals might be perfect. But if you’re rewiring a fuel injector harness or marine steering console, you may stick with the crimp and seal method approved by OEMs and standards. There’s no shame in using solder-seal connectors within their comfort zone – just don’t use them outside it and expect zero issues.

-

Quality and technique matter: If there’s one takeaway, it’s that you should invest in good solder seal wire connectors and practice using one or two before trusting them on an important job. The industry testing showed a stark contrast between a reputable brand’s product and a cheap alternative. The good connector achieved everything it was supposed to (strong solder penetration, secure seal), while the bad one barely melted properly and had almost no holding power. So, stick to known brands (Haisstronica, 3M, etc., which advertise proper materials and have good reviews) – the best solder seal wire connectors will have thick, low-impurity solder rings and robust adhesive. And follow the recommended technique: use a proper heat gun (avoid open flames if possible, as they can char the tubing before the solder melts), heat evenly from the center (solder) out to the edges, and give the joint a moment to cool before tugging it. When done right, you’ll have a neat, clear, solid splice. Done wrong, you might have a partially melted solder or a charred tube – which will not perform as intended.

Our Top User-friendly Picks

Speed up identification and selection with gauge marks on every sleeve. Haisstronica pairs solder and shrink tube engineering with thick-wall solder sleeves for strain relief, plus convenient solder stick connectors that bond fast, shrink clean, and pass the tug test.

👉 Pick a Haisstronica solder wire connector for rugged, corrosion-resistant splices.

In conclusion, solder-seal connectors are a valuable tool for wiring that offer convenience and efficiency. They truly shine in scenarios where a quick, sealed connection is needed without the luxury of a full workshop – such as field repairs or DIY upgrades. They are generally water-resistant enough for most automotive and marine needs, but calling them 100% “waterproof” for all conditions is a stretch. By understanding their construction, you can appreciate why they seal out moisture well – and also why they might let you down if misused in high-stress conditions.

So, when you buy and use solder-seal wire connectors, set your expectations accordingly: they can save you time and give you a clean, professional-looking splice that shrugs off water and corrosion, as long as you deploy them in suitable conditions. Use them to replace messy “twist and tape” fixes with something far more robust, but don’t abandon common sense for critical wiring where a failed connection could spell disaster. In those cases, a crimp or other connector might still be the better choice (or at least use the solder-seal as a temporary fix until a proper repair is done).

Lastly, always remember to double-check your work. Give the cooled splice a gentle pull test – a properly soldered wire connector won’t pull apart easily. If it does, re-do it. And store any unused connectors properly (extreme heat can pre-melt the solder in storage!). With these practices, you’ll find solder-seal connectors to be a fantastic addition to your electrical toolkit, providing reliable service in the right applications. They bridge the gap between soldering and crimping, and when used with realistic expectations, they certainly live up to the hype as a convenient, water-resistant wire connection solution.

References: