How They Work (wire connectors solder)

At a glance, wire connectors solder (often called solder seal connectors, solder sleeves, or heat shrink solder connectors) look like short sections of clear heat-shrink tubing with a colored low-temperature solder ring in the middle and two adhesive rings on the sides. During installation you insert stripped conductors from both sides so the bare copper overlaps under the solder ring. Gentle, even heat collapses the ring, wets the copper, and simultaneously activates the hot-melt adhesive that bonds the sleeve to the wire jackets, creating a sealed splice.

What’s happening physically:

-

Metallurgical bond at the core. The solder ring (typically a low-melt alloy with flux) flows into the strand bundle by capillary action. When shiny and fully collapsed, it produces a continuous conductive path.

-

Mechanical strain relief at the edges. Dual adhesive rings flow and grip the insulation, distributing stress away from the joint and excluding moisture.

-

Visual QC. The clear sleeve lets you verify overlap, solder wetting, and adhesive extrusion.

By contrast, an adhesive-lined crimp butt splice uses a metal barrel (tin-plated copper) mechanically compressed around the conductor with a ratcheting crimper, then covered by adhesive-lined heat-shrink. You’re relying on cold-formed metal-to-metal contact for conductivity and pull strength, not solder. This is the dominant approach in high-vibration harnesses because the crimped barrel remains ductile and the joint can flex without creating a rigid heat-affected zone. You’ll see these marketed as sealed crimp connectors, crimp and seal connectors, or a solder crimp connector (hybrids exist, but most pro shops keep the operations separate for control).

Where wire connectors solder excel:

-

Clean, compact splices with integrated sealing in one heat step.

-

Minimal tool set (heat gun with reducer nozzle).

-

Transparent body gives instant confirmation of a good melt and seal.

Where crimp-then-shrink excels:

-

Vibration resistance and fatigue life in mobile platforms (vehicles, marine engines, industrial machines).

-

Standards compliance in sectors that favor crimped splices for field serviceability and consistency.

-

Temperature margin near hot zones where solder can creep over time.

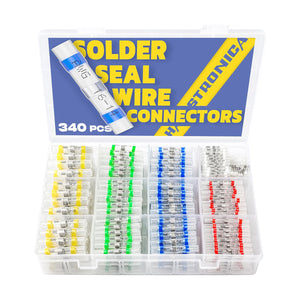

Want an organized assortment that covers AWG 26–10 with color codes? Try Haisstronica’s 340-pcs heat-shrink solder-seal kit

Decision Matrix (wire connectors solder)

Use this quick rubric to choose confidently. Each line reflects what many workmanship standards and field audits look for in reliable harness work.

1) Vibration & flex

-

Low–moderate vibration, supported harness, interior zones: wire connectors solder are fine when properly installed (overlap under the ring, full adhesive flow).

-

High vibration, engine bays, long flex loops: Prefer adhesive-lined crimp butt connectors. The metal barrel and strain relief handle flex fatigue better than a rigid soldered core. (Key idea: crimp vs solder under vibration → crimp wins.)

2) Temperature exposure

-

Ambient to ~85–105 °C away from heat sources: Either method works if the sleeve/tubing ratings match the environment.

-

Near exhaust manifolds/turbos or sustained >105 °C: Favor crimp-and-seal; soldered joints can soften or creep. Select high-temp tubing and adhesive.

3) Moisture, splash, and salt

-

Occasional splash, interior cabins, trunk runs: Both approaches seal well when the adhesive flows uniformly.

-

Bilge, exterior, de-icing salt, pressure wash: Choose products explicitly rated for sealing (solder seal connectors, sealed crimp connectors) and confirm adhesive extrusion. Marine pros often prefer crimp-and-seal in long-term wet environments because the joint stays more flexible.

4) Standards & inspection

-

If your shop follows IPC/WHMA-A-620, NASA workmanship, or similar: crimped splices are generally the baseline, with soldered splices allowed in specific circumstances and with controls. Aviation and some OEM auto procedures strongly prefer crimp for maintainability and fatigue.

-

DIY, light automotive accessories, home/van builds: wire connectors solder offer speed and tidy results, provided you heat correctly.

5) Accessibility & rework

-

Tight spaces, no room for a crimp tool nose: wire connectors solder + heat gun wins.

-

Likely future service or field replacement: Crimp-and-seal is easier to undo cleanly and re-terminate.

6) Conductor type

-

Fine-strand copper (typical automotive/marine primary): Both methods are great.

-

Solid conductor (household branch circuits, certain sensors): Use method endorsed by the terminal manufacturer; many sleeves are optimized for stranded. If you must splice solid in low-vibration scenarios, confirm overlap and achieve a perfect wetting with wire connectors solder; otherwise choose the right crimp barrel specified for solid wire.

7) Wire size & jacket OD

-

wire connectors solder rely on the right AWG range and jacket OD for the sleeve to shrink and seal. If jackets vary widely, reach for 3:1 or 4:1 shrink sleeves or choose crimp-and-seal with an appropriately sized barrel and tubing.

8) Tooling skill & repeatability

-

Occasional users often get more consistent outcomes with wire connectors solder because visual cues (solder ring collapse, adhesive beads) guide them.

-

Trained techs with a calibrated ratcheting crimper and color-coded barrels will deliver extremely repeatable crimp-and-seal joints that pass pull tests.

Bottom line:

-

Pick wire connectors solder for quick, clean, sealed splices in moderate environments (trailers, interior automotive circuits, marine cabin wiring, sensors).

-

Pick crimp-and-seal for high-vibration, high-temperature, or standards-controlled work where fatigue and serviceability rule.

Stock the option you’ll use most: Haisstronica 340-pcs solder-seal kit (AWG 26–10) keeps all sizes at hand and labeled for speed.

Cost & Efficiency (wire connectors solder)

Procurement managers care about more than unit price. Consider time to first good splice, tool amortization, rework rate, and lifecycle risk.

1) Unit cost vs total installed cost

-

Unit price: Adhesive-lined crimp butt connectors and solder sleeves are often within cents of each other at volume.

-

Tool cost:

-

wire connectors solder need a heat gun and good technique—most shops already have these.

-

Crimp-and-seal needs a quality ratcheting crimper matched to the barrels (insulated/non-insulated dies). The tool cost is amortized quickly in production, but it is an up-front expense.

-

-

Throughput: For many techs, a solder sleeve is one motion (heat) rather than two (crimp, then heat). In tight quarters or overhead work, that can be meaningfully faster.

2) First-pass yield & learning curve

-

With wire connectors solder, visual QC is built in. You can see solder collapse and adhesive flow—fewer hidden defects. Common mistakes include too little overlap under the solder ring or scorching the tube with an open flame.

-

With crimp-and-seal, the ratchet mechanism ensures full compression every time, but only if you picked the correct barrel size and used the correct die nest. Novices sometimes under-strip or half-insert conductors. Color-coded barrels and a ratchet crimping tool minimize this risk.

3) Rework cost and field failure risk

-

A bad heat cycle on wire connectors solder (cold joint, no adhesive bead) may hold in the shop but fail under pull or moisture. You must train installers to heat the ring first and chase adhesive outward.

-

A marginal crimp can pass a casual tug test but fail in months if the crimp wings didn’t fully form or strands were cut during strip. Ratcheting tools, correct die selection, and periodic pull tests mitigate this.

4) Inventory simplicity

-

wire connectors solder come in four primary color sizes (white/red/blue/yellow) to match AWG ranges and are easy to kit.

-

Crimp-and-seal requires barrels in multiple sizes plus adhesive-lined tubing. Many shops already carry both; the incremental stocking burden is small.

5) Lifecycle economics

-

In fleets and marine service, avoiding callbacks is worth far more than pennies per connector. If a harness section lives on a vibrating frame, crimp-and-seal’s fatigue performance typically pays for itself in avoided rework.

-

In low-vibration, moisture-prone areas (trailer lights), wire connectors solder produce fast, tight, waterproof splices that reduce corrosion-related comebacks.

6) Practical timing benchmarks (for planning)

-

Experienced tech, mid-gauge splice in easy access:

-

Solder sleeve: prep + heat ≈ faster overall, especially with a reducer nozzle and consistent technique.

-

Crimp-and-seal: slightly longer due to two operations, offset by zero learning curve once dies are set.

-

-

Production lines: crimping with ratcheting tools standardizes compression force and is easy to document for QA; sleeves are great for service kits and field retrofits where electricity for a heat gun is available.

Cost conclusion: If you’re a mobile tech or DIYer doing mixed repairs, wire connectors solder offer outstanding value per minute. If you’re building or maintaining high-vibration harnesses, the economics tilt toward crimp-and-seal thanks to fatigue resistance and straightforward audit trails.

If sleeves fit your workflow, pick a kit that’s already sorted by AWG. Haisstronica 340-pcs heat-shrink solder-seal kit is a solid all-rounder

Conclusion

There’s no single winner—there’s a best fit for each job:

-

Choose wire connectors solder when you want a compact, sealed in-line splice that installs quickly with visual quality cues. They’re ideal for interior automotive accessories, trailer lighting, RV solar tie-ins, and marine cabin circuits—any place with moderate vibration and a need for moisture exclusion.

-

Choose adhesive-lined crimp butt connectors for high-vibration or high-temperature zones, and whenever your workmanship standard or inspection regime prefers cold-formed connections for fatigue life and maintainability.

Many pros carry both: sleeves for fast, sealed pigtails and crimp-and-seal for chassis harnesses. If you’re building or servicing mixed systems, that two-tool approach is hard to beat.

Our Top User-friendly Picks

Get a tighter, longer-lasting splice with Haisstronica’s butt connector with solder. Our hot-melt adhesive fills gaps, then hardens quickly to create a waterproof, corrosion-resistant bond. The heat-shrink sleeve shields against scuffs, cuts, and vibration, while gauge markings simplify picking the right size. Whether you solder on wire connectors for marine, trailer, or automotive lines, these premium solder connectors ensure consistent performance in demanding conditions.

Ready to stock your kit?

Get the Haisstronica 340-pcs Heat-Shrink Solder-Seal Wire Connectors (AWG 26–10) here

References

-

IPC/WHMA-A-620—Requirements and Acceptance for Cable and Wire Harness Assemblies

-

L 486—Wire Connectors and Soldering Lugs for Use with Copper Conductors

-

ABYC E-11—AC & DC Electrical Systems on Boats (marine wiring best practices)