Size & Mix: Choosing the Right Range of Solder Connectors

One of the first hallmarks of a quality solder connector kit is the range of connector sizes included. A good kit offers a well-thought-out mix of sizes to accommodate different wire gauges (measured in AWG). Why is this important? Because using the correct size solder seal connector for your wire ensures a proper fit – the heat shrink tubing can fully shrink down, and the low-melt solder ring is appropriately sized to fuse the stripped conductors. High-quality kits typically cover common wire sizes from very small electronics wires to heavier automotive cables. For example, many solder & seal connector assortments use standard color codes for each size: red, blue, and yellow connectors corresponding to AWG ranges (approximately Red for 22–16 AWG, Blue for 16–14 AWG, and Yellow for 12–10 AWG). Some kits even include white connectors for ultra-fine wires around 26–24 AWG, which is great for delicate wiring on sensors or audio leads.

To illustrate, a quality solder seal connector kit might contain connectors in four sizes such as:

-

White (26–24 AWG): Extra-small solder sleeves for thin wires in electronics or instrument wiring.

-

Red (22–18 AWG): Small connectors for light-gauge wiring like automotive lighting, speakers, or RC hobbies.

-

Blue (16–14 AWG): Medium connectors for typical vehicle wires and general wiring projects (e.g. 12V accessory wires).

-

Yellow (12–10 AWG): Large connectors for heavier gauge wires such as power feeds, marine wires, or automotive battery accessories.

Having this full range ensures you can solder and seal anything from a tiny signal wire to a thicker power cable. Lesser kits might skimp on the variety or quantity of certain sizes – for instance, providing mostly mid-sized connectors but very few small ones – which can be frustrating when you run out of the size you need. A well-balanced kit from a reputable brand will include plenty of each size in useful proportions. In fact, some brands adhere to industry standards on assortment. For example, Wirefy (a respected connector supplier) notes that their connector kits come with the most common terminal types and 3 standard sizes (red, blue, yellow) to cover 22–10 AWG ranges, suitable for marine, automotive, and home electrical projects. Quality kits also often include a gauge chart or have the tubing printed with gauge sizes to help you quickly identify the right connector – a small but helpful detail. Overall, when evaluating a solder connector kit, check that it covers the wire sizes you’ll need. A kit like Haisstronica’s 180-piece set, for example, spans AWG 26–10, indicating it’s designed to handle a wide spectrum of wiring tasks (from fine wire splices to robust solder wire connections in automotive use). A comprehensive size mix is the foundation of a versatile kit and is the first sign that the manufacturer has put thought into the DIYer’s needs.

👉 Get leak-proof Haisstronica butt connectors with solder for tough environments.

Adhesive Quality: Waterproof Sealing & Durable Connections

Another core component of a quality solder & seal connector is the adhesive-lined heat shrink tubing – essentially the “seal” part of solder and seal connectors. This adhesive is what differentiates these connectors from a plain heat shrink or a simple solder joint. When heated, the tubing shrinks and an inner ring of hot-melt adhesive (typically at each end of the connector) melts and flows. A good adhesive will bond tightly to the wire insulation, creating a waterproof seal around the wire joint. This keeps out moisture, dirt, and corrosion, effectively turning your splice into a weatherproof, insulated link.

Not all adhesives are created equal. High-quality solder seal connectors use premium adhesive formulations (often EVA – ethylene-vinyl acetate – hot melt adhesive) that flow evenly and hold up over time. For instance, Master Appliance’s professional Solderseal connectors use adhesive-lined polyolefin tubing which provides a water and contaminant resistant seal, preventing wire corrosion. Similarly, Del City (an automotive electrical supplier) highlights that the adhesive lining in heat shrink connectors creates a durable, moisture-resistant seal that protects the connection from corrosion and harsh environmental factors. In short, the adhesive quality determines whether your soldered wire connectors will just shrink or truly “shrink and seal.”

So what should you look for? First, the packaging or specs might mention terms like “marine-grade” or an IP rating (IP67/IP68) for the connectors – a sign that the adhesive, once melted, forms a watertight bond. In fact, many products advertise a “marine-grade waterproof design” where heat shrink tubing and adhesive lining ensure a watertight seal. Quality connectors will often have a thicker dual-wall shrink tubing (with a 3:1 or even 4:1 shrink ratio) so that as it shrinks, it tightly conforms to the wire and forces the melted adhesive into all gaps. If the shrink ratio is too low or the tubing too thin, you might see voids or dry spots after heating – an indicator of inferior adhesive or tubing. Premium connectors, on the other hand, shrink evenly and you’ll observe a bit of adhesive extruding at the ends of the tubing when properly heated – a good visual confirmation of a fully sealed joint.

Another aspect is the solder itself (since solder and adhesive work together in these connectors). Better kits use a low-temperature solder ring with built-in flux. Flux is critical for a solid solder bond – it cleans oxides off the wire as the solder melts, ensuring the solder wets the copper. High-grade connectors use “no-clean” flux coatings on the solder so that you don’t have corrosive residues and to guarantee good conductivity. The solder quantity and melting point are tuned so it flows fully through the twisted wire ends, but doesn’t require excessive heat that could burn the tubing. In cheap connectors, you might find the solder ring is scant or doesn’t melt completely, which results in a weak “cold” joint. According to industry testing, the difference can be stark: in a Practical Sailor evaluation, brand-name solder seal connectors (3M’s in this case) achieved excellent solder flow and strong tensile strength – the completed splice was actually stronger than the wire itself – whereas a no-name connector had poor solder wetting and pulled apart easily. The takeaway is that quality varies, and a good kit will use well-engineered solder sleeves with adequate solder and effective adhesive. Avoid no-name or super-cheap connectors with suspiciously thin tubing or little solder – they may look similar but won’t perform the same. As the Practical Sailor test concluded, “cheap connectors may look good, but in reality [can] be no better than twisting wires together and covering with tape… Under no circumstances buy no-name solder seal connectors.” Strong words, but it underlines that investing in a quality kit ensures your soldered connections are truly solid and sealed for the long run.

👉 Keep Haisstronica solder sticks handy for quick, clean electrical bonding.

Tools & Extras: Making Soldering Connections Easy for DIYers

Beyond the connectors themselves, consider what tools and extras come with (or are recommended for) a quality kit. One big selling point of solder & seal connector kits is that you don’t need a soldering iron or crimp tool – the connectors are essentially self-soldering and self-sealing. You’ll still need a heat source, of course, and the preferred tool is a heat gun. High-quality kits will often explicitly mention this and provide guidance on proper heating. Some comprehensive kits even bundle a compact heat gun or torch in the package, giving you an all-in-one solution for wiring repairs. For example, there are large kits on the market that include hundreds of solder seal connectors along with a portable heat gun and organizer case, so you’re ready to go out of the box. Even when a heat tool isn’t included, a reputable brand like Haisstronica will recommend using a high-temperature heat gun (around 600–800°F output) to ensure the solder fully melts and the tubing shrinks uniformly. This is an important tip for hobbyists: avoid open flames like lighters whenever possible. While it’s technically possible to use a lighter or small torch in a pinch, it’s harder to heat evenly and you risk charring the tubing or not melting the solder correctly. As one heat-shrink expert notes, “while the lighter can emit sufficient heat, it can also mark the tubing with black soot and/or can damage the material and wires if the flame is held too close.” In other words, a controlled heat gun is the safest way to get a clean, reliable result. If you must use a flame, keep it moving and at a distance – but the best kits might save you the trouble by either including a proper heat tool or at least designing the connectors to work with common heat gun temperatures (often around 130°C shrink temp and ~~138°C solder melt temp).

Aside from heat tools, what extras might a quality kit include? Here are a few possibilities and signs of a thoughtful kit:

-

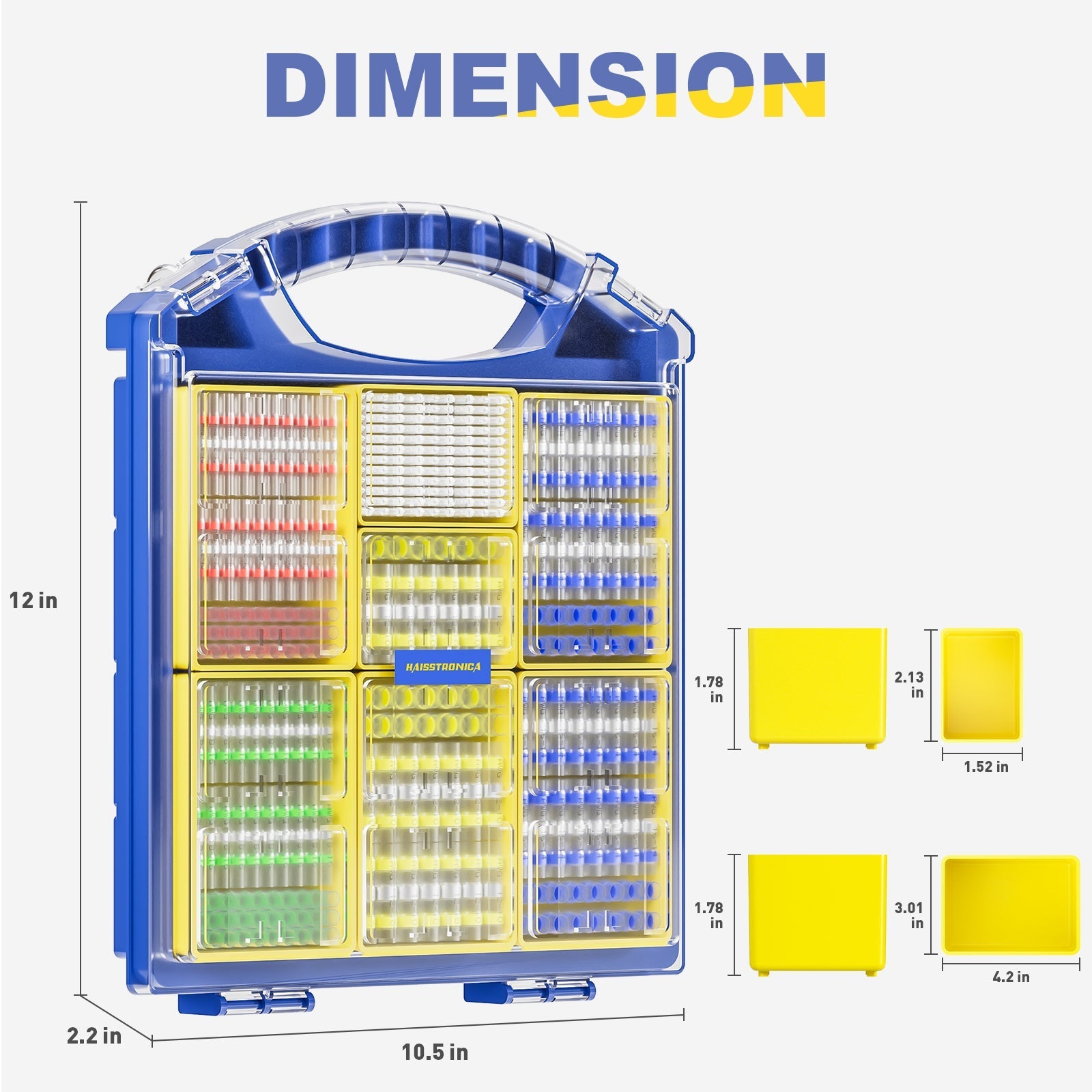

Sturdy Storage Case: Almost all decent kits come in a compartmentalized box. A quality case will have clear compartments for each connector size, sometimes labeled with the size/color and AWG range. This keeps your solder connectors organized and prevents moisture from getting to them when stored.

-

Color Code Chart or Markings: As mentioned, good kits either print the gauge range on each connector or include a reference chart. This helps ensure you pick the right size every time. Little details like gauge markings on the tubing show the manufacturer cares about the user’s convenience.

-

Instruction Sheet or Guide: Beginner DIYers will appreciate a kit that comes with a simple how-to guide for making a proper solder splice using these connectors. The steps (strip wires, overlap, heat evenly from the center outwards) are not complicated, but having instructions or even a QR code to an online tutorial is a nice extra. It shows the brand stands behind helping customers get it right.

-

Additional Tools: Some kits might throw in a basic wire stripper or a pair of heat-resistant gloves, etc. While not necessary, extras like this indicate a “premium” kit aimed at being beginner-friendly. At the very least, ensure you have a good wire stripping tool on hand – stripping the correct length of insulation (usually about 1/4 inch) is key before inserting wires into the solder connector.

-

Heat Shrink Extras: Occasionally, kits may also include a few pieces of plain heat shrink tubing or solderless connectors (like crimp terminals with heat shrink) for cases where a solder sleeve might not be ideal. This isn’t very common, but some larger kits bundle various connection options. The focus, however, is on the solder & seal butt connectors.

In short, the best solder connector kits are designed to make the process as foolproof as possible for you. They recognize that many users are DIYers or hobbyists who want a quick, reliable way to splice wires without special equipment. The convenience of these connectors is that you “crimp” by simply overlapping wires and you “solder” by applying heat – the connector does the rest, melting the solder to join the wires and shrinking the tube to seal it. No crimping tool, no soldering iron, and no messy rosin or electrical tape needed. If a kit includes the right tools (or if you have your own heat gun ready) and clear extras like a storage case and guide, you’re set up for success. You’ll be able to create soldered wire connections that are strong electrically and protected mechanically in just seconds. This ease-of-use is exactly why solder & seal connectors are popular for automotive wiring, trailer lights, boat electronics, and general DIY electrical fixes – they simplify the job while still yielding a professional-grade result.

👉 Make flawless joints with a Haisstronica soldering butt connector every time.

Conclusion: The Mark of a Quality Kit

A quality solder & seal wire connectors kit empowers you to tackle wiring projects with confidence. It’s the combination of a comprehensive size range, high-grade materials, and thoughtful extras that truly sets the best kits apart. With the right assortment of connector sizes, you won’t find yourself in the middle of a project lacking the proper connector for a wire. With superior adhesive-lined heat shrink and low-temp solder, you can trust that each solder splice you make will be electrically sound and hermetically sealed against the elements. And by having the proper tools and guidance on hand, even a novice can achieve a solid soldered connection on the first try.

It’s worth noting that solder seal connectors are intended to give you “the best of both worlds” – the electrical bonding of solder and the environmental protection of a heat-shrink seal (much like a crimp-and-seal connector, but without needing to physically crimp). When installed correctly, they form a permanent bond that often matches the performance of traditional solder-and-heat-shrink done with an iron. In fact, testers have found that a good solder seal connection can be as strong as a hand-soldered joint or quality crimp. In one test, a 3M solder sleeve withstood pull forces until the wire itself broke, outperforming cheaper connectors that failed at the solder. And in marine wiring use, experienced electricians note that these sealed solder connectors can provide an excellent waterproof connection – as long as you use clean (tinned) wires and proper heating technique. In everyday automotive and home DIY scenarios, a well-made solder seal splice is more than robust enough, offering low resistance and good vibration resistance thanks to the strain-relief of the shrink tube. (Do keep in mind, however, that in high-vibration or high-heat areas like engine compartments, some professionals still prefer crimp connectors or a combination crimp-and-solder approach as an extra precaution. It’s always important to follow best practices for critical wiring.)

For general-purpose wiring, though, a quality solder & seal kit is a fantastic tool in the DIYer’s arsenal. It allows even those new to soldering to create tidy, durable splices with minimal equipment. No more frayed twisted wires under electrical tape or unreliable solderless connectors that might pull apart – instead, you get a clean-looking transparent sleeve showing a shiny solder joint and adhesive oozed at the ends, confirming a successful solder and seal. The connections are waterproof, insulating, and strong, ideal for automotive repairs (headlights, stereo wiring, trailer hookups), outdoor lighting, or hobby electronics that need that extra protection.

In summary, when evaluating or shopping for a solder seal wire connector kit, remember the key ingredients of quality: size & mix, adhesive quality, and tools/extras. A kit like Haisstronica’s, which offers a broad AWG range, uses marine-grade shrink tubing with plenty of adhesive, and comes from a company known for electrical connector expertise, is a prime example. Such a kit will save you time and headaches, and most importantly, give you reliable electrical wire connections that you can trust in your DIY projects. With the right kit in hand, you’ll be ready to solder, shrink, and seal your way to wiring success – all while enjoying a simple, one-step process that delivers professional results.

Our Top User-friendly Picks

For larger gauges and vibration-prone circuits, choose heat shrink with solder that wets the joint and seals tight. Haisstronica solder seal connectors create uniform bonds that resist pull-out. Tidy solder splices deliver low-resistance continuity in trailers, motorcycles, and utility equipment.

👉 Prefer tool-free? Try Haisstronica solderless electrical connectors for quick fixes.

References:

practical-sailor.com

masterappliance.com

delcity.net

shrinkshop.com