What Is a “Wire Terminal”? (Crimp Connectors Explained)

A wire terminal is a device attached to the end of a wire to safely connect it to another wire or an electrical component. In simple terms, it’s a connector (often metal) that you crimp or solder onto a stripped wire end, creating a reliable termination point. Wire terminals come in many shapes and sizes to accommodate different wire gauges and attachment methods. They may mount onto screws or studs (for example, ring terminals bolting to a battery or ground post) or plug into other connectors (like male/female spade crimp connectors used in automotive wiring). When a wire is properly terminated with a connector, it ensures a secure electrical contact and strain relief, preventing the wire from coming loose or fraying. Failing to terminate a wire properly can lead to signal loss or unsafe conditions, so using the right terminal is critical.

One major advantage of using crimp terminals is that they allow quick connection and disconnection without needing to repeatedly solder or twist wires. Once a terminal is crimped onto a wire, that wire can be easily “plugged” or “unplugged” from devices or other wires via the connector interface. For example, a spade terminal on a speaker wire lets you slide the wire on and off a speaker’s tab easily. This flexibility is a big reason crimps are popular in everything from car electronics to home DIY projects – they make wiring maintenance and changes much easier.

👉Durable crimper die options—Haisstronica engineered steel.

Crimp vs. Solder: In the past, people often soldered wires or simply wrapped them with tape, but crimping is now preferred in many cases. A proper crimp, made with a dedicated crimping tool, creates a gas-tight cold weld between the wire and terminal. Essentially, the crimp tool’s dies compress the terminal barrel around the wire with enough force to deform both, bonding them without heat. This forms a solid electrical connection that is highly resistant to vibration and corrosion – essential for automotive and aerospace wiring. In fact, a well-executed crimp can be stronger and more reliable than a soldered joint. While soldering can weaken with vibration or temperature changes, a good crimp remains tight and secure under harsh conditions. The key is to use a proper electrical crimping tool (not just pliers) to apply the correct pressure for that terminal and wire gauge.

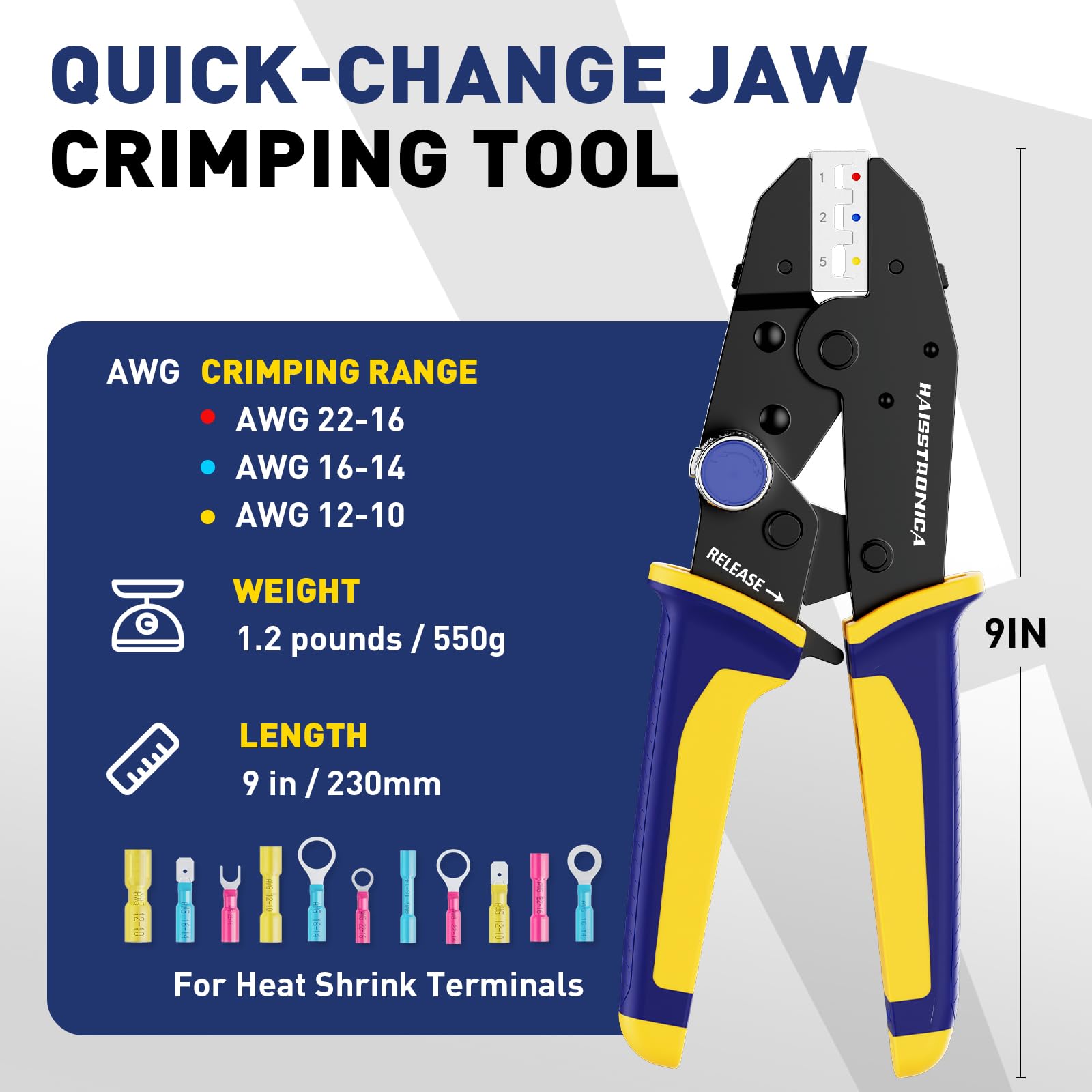

Choosing the Right Size: Wire terminals are categorized by the wire size (gauge) they fit, and using the correct size is very important. Most insulated crimp connectors for common wires use a color code: red for 22–16 AWG, blue for 16–14 AWG, and yellow for 12–10 AWG. These colored insulation sleeves indicate the compatible wire range and also correspond to the crimping die you should use. Always match your wire gauge to a terminal of the same range, and use the appropriate crimp die on your tool for a secure compression. For very thick wires (larger than 10 AWG), usually non-insulated lugs are used – these often come with a separate insulating sleeve or are covered with heat shrink tubing after crimping. Using the right size and proper crimping technique will yield a strong connection that won’t pull out.

👉Need a cable end crimper? Haisstronica handles terminals cleanly.

Common Terminal Types & Use Cases (Crimp Connector 101)

There is a wide variety of wire terminals out there, each suited for specific purposes. In this section, we’ll cover the most common types of crimp connectors and their typical use cases. By understanding the differences, you can choose the right connector for your project – whether you’re repairing an appliance cord, wiring a car stereo, or working on a DIY electronics project. The following are some of the common wire terminal types you’re likely to encounter:

-

Ring Terminals: A ring terminal (or crimp ring terminal) has a round O-shaped connector end. The ring slips over a bolt or screw, making a very secure connection that won’t come loose unless the fastener is removed. Ring terminals are commonly used to attach wires to grounding points or battery posts in automotive and marine settings. For example, you’ll find ring terminals connecting battery cables to the battery terminals, or grounding wires to a car’s chassis. They are popular because they offer a solid connection with virtually zero chance of accidental disconnection – the ring is captive under the screw head or nut. You can find ring terminals in various sizes to fit different bolt diameters, and in insulated or non-insulated versions.

-

Spade/Fork Terminals: Spade terminals (also called fork terminals due to their prong shape) have an open U-shaped end. Like ring terminals, they attach to screws or studs – but because the end is open, you can slip them under a screw head without completely removing the screw. This makes installation and removal quicker. Fork or spade connectors are often used in automotive and industrial equipment where wire connections need to be easily replaceable (for instance, connecting wires to a barrier strip or relay). They come in locking or non-locking styles – a locking fork “hugs” the stud for a more secure hold, whereas a standard fork simply slides in. Spade terminals are great when you have limited space or need to frequently disconnect the wire, though they aren’t as vibration-proof as ring terminals (since they could slip out if the screw loosens).

-

Quick-Disconnect Spade Connectors (Blade Terminals): When most people say “spade connector,” they often mean the flat blade-style quick-disconnect terminals that come in male and female pairs. These are very common crimp wire connectors in automotive and appliance wiring. The male connector is a flat blade, and the female is a receptacle (socket) that the blade slides into. When joined, they create an inline connection that can be easily unplugged as needed. You’ll see these on speaker wires, car stereo harnesses, and many electronic devices for the user-serviceable connections. They are sometimes called blade connectors or just male/female disconnects. Quick-disconnect spades are typically insulated to prevent shorts, and are available in fully-insulated versions (often translucent nylon housings) to further protect the connection. They are extremely versatile – for example, a female spade connector is commonly used to connect to equipment terminals (like switch or relay terminals), while the corresponding male may be attached to the wire from the power source.

-

Butt Splice Connectors: A butt connector (butt splice) is a cylindrical coupler used to join two wires end-to-end, essentially splicing them together. Each wire is inserted into opposite ends of the butt connector’s metal barrel, and then both ends are crimped, forming an inline splice. Butt splices are the go-to solution for repairing a broken wire or extending a wire by connecting it to another. The resulting connection is inline (no branching), which makes it easy to insulate and wrap with other wires neatly. For example, if you cut a wire to install a device and later need to reconnect it, a butt crimp creates a solid, continuous connection as if the wire were never cut. Butt connectors come in uninsulated form (often used with heat shrink tubing for waterproofing) or pre-insulated with vinyl/nylon, and even in heat shrink butt connector variants that seal the splice when heated. They are very reliable when crimped properly, providing good mechanical strength and conductivity.

-

Crimp Caps (Closed-End Connectors): Crimp caps are a simple type of splice connector shaped like a small plastic “thimble” or cap. You insert two or more stripped wire ends into the cap and crimp down on the metal sleeve inside, which tightens onto all the wires. These closed-end crimp connectors are often used in home electrical or car audio installations for joining multiple wires together securely in a bundle. For instance, connecting two ground wires to a single return line can be done with a crimp cap. They provide a reliable connection, though the wires will all enter from the same end, which can make the joint a bit bulky. Because the wires bend inside the cap, it’s not as neat inline as a butt splice (the wires will exit at a 90° angle to the cap). Crimp caps typically have a vinyl insulation shell (often white or semi-transparent) and are crimped with a standard crimp tool or even pliers in some cases. They are quick and effective – crimp caps are particularly popular in aftermarket car stereo wiring, where you might join a stereo’s harness wires to the vehicle’s wires by groups of two.

-

Bullet Connectors: Bullet connectors consist of a round male bullet-shaped pin and a corresponding female socket. They function similarly to blade disconnects (allowing wires to be easily connected/disconnected) but with a cylindrical mating interface. These were commonly used in older automotive and motorcycle applications and are still found in some wiring harnesses. For example, many classic cars or motorcycles use bullet connectors for lighting wires. The male bullet snaps into the female barrel to complete the circuit. Bullet crimp connectors aren’t as widely used today in new designs – blade/spade connectors have largely overtaken them – but you can still use bullets for repairs or custom projects, especially if you want a quick-disconnect in a tight space where a blade connector wouldn’t fit. Keep in mind that bullets can sometimes be fiddly; they can be harder to pull apart, and if not fully inserted they might loosen. Also, they are a bit less common on shelves than spade terminals. They do come in standard sizes (often Bullet connectors often in 22-16 AWG red, 16-14 AWG blue, etc., with one end male, one end female).

👉Choose ratchet crimp tools—Haisstronica force, perfect finish.

Those are the primary types of crimp terminals most DIYers and professionals will use frequently. There are a few other specialized connectors worth mentioning briefly:

-

Quick Splice T-Tap Connectors: These connectors allow you to tap into an existing wire without cutting or stripping it. A T-tap has a metal blade inside a plastic clip; when closed over an insulated wire, it pierces the insulation and makes contact with the conductor. A male spade connector is then plugged into the T-tap to branch off the connection. This is useful for adding a new wire to an existing circuit (for example, tapping into a running light wire to add a side marker light). While convenient, these are somewhat controversial – they can weaken the original wire if not done properly. Use them for quick fixes or when soldering or proper splicing isn’t feasible. A removable T-tap is preferred over the permanent “side-by-side” taps.

-

Ferrule Terminals (Bootlace Ferrules): These are tubular end terminals used primarily in screw-clamp terminal blocks (common in industrial control panels or audio equipment). A ferrule is a small metal tube, sometimes with a flared plastic collar, that you crimp onto the end of a stranded wire. It creates a neat pin-like termination that can be inserted under a screw clamp or into a connector. Ferrules prevent the stranded wire from fraying and ensure all strands are compressed evenly under the screw. They’re very useful for professional wiring jobs, though not usually found in automotive use. If you’re wiring something like an Arduino or an amplifier with set-screw terminals, ferrule wire end crimps make the job easier and more reliable.

As you can see, there’s a crimp connector for every scenario – from fork crimps that let you slip under a screw, to butt crimps that join wires, to quick disconnects for modular wiring. The key is to pick a terminal suited for your connection type and environment. Always consider the current load, the wire size, and whether the connection might need to be unplugged or endure harsh conditions (heat, moisture, vibration). Using the correct terminal type, and crimping it properly, will save you from electrical headaches down the road.

👉Accurate spade connectors crimping tool—Haisstronica for tidy panels.

(Below is a handy reference table summarizing common terminal types and their uses for quick review.)

| Terminal Type | Description & Common Use |

|---|---|

| Ring Terminal | O-shaped connector for screws or studs. Used for secure, bolted connections (e.g. ground wires, battery terminals). Won’t disconnect unless screw is removed. |

| Fork (Spade) Terminal | U-shaped open connector for screws. Easy to attach/remove without fully removing screw. Used in relay bases, fuse blocks, or tight spaces. Not as locking as a ring terminal. |

| Blade Quick-Disconnect | Flat spade connectors (male blade and female socket pair). Used for quick-connect wire ends in automotive and appliances (speaker wires, switches). Allow fast disconnect for service. |

| Butt Splice Connector | Tube-shaped connector to join two wires end-to-end (in-line splice). Used for repairing or extending wires. Provides strong inline connection; often insulated or heat shrink for protection. |

| Crimp Cap (Closed-End) | Plastic capped connector that joins multiple wires together in one crimp. Common in audio and lighting installs to tie wires together. Quick to use; wires enter one side of cap. |

| Bullet Connector | Round bullet-shaped male/female pair for disconnectable connections. Used historically in auto/motorcycle wiring; still used for certain harnesses. Compact but less common today. |

| Ferrule (Bootlace) | Small tubular crimp that forms a pin end on a stranded wire. Used for inserting wires into screw terminals (control panels, audio amps) for a neat, fray-free connection. |

Insulation & Sealing Options (Vinyl vs Nylon vs Heat Shrink)

Beyond the metal part of a terminal, another key aspect is the insulation on the connector. Crimp terminals come either uninsulated or with various insulating sleeve materials, and some offer sealing properties against moisture. Choosing the right insulation type can greatly affect the durability and safety of your connection, especially in different environments. Let’s look at the common insulation and sealing options for wire terminals and crimp on wire connectors:

-

Vinyl/PVC Insulation: Many inexpensive crimp connectors (the red, blue, yellow terminals you find in hardware stores) use Vinyl or PVC plastic insulation. This is the basic insulated terminal style. The hard plastic sleeve covers the crimp barrel and provides electrical insulation to prevent shorts. Vinyl-insulated terminals are cost-effective and fine for general use, but they offer minimal environmental protection. PVC insulation can become brittle over time, especially with heat and sunlight exposure, potentially cracking with age. There is also no sealing – the wire entry and barrel ends are open, so moisture can still reach the metal inside. In short, vinyl insulation protects against accidental short-circuits, but does little else to protect the connection long-term. Use vinyl-insulated crimps for indoor projects or non-critical connections where cost is a concern and the wiring is not exposed to harsh conditions.

-

Nylon Insulation: Nylon-insulated terminals are a step up in quality and durability. Nylon sleeves are typically more flexible and resilient than PVC. They can withstand higher temperatures and won’t crack as easily. Often, nylon crimp connectors are designed for a “double crimp” – one crimp on the wire and another on the insulation for extra strain relief. This means the wire is gripped more securely, reducing the chance of it pulling out under stress. However, like PVC, nylon by itself doesn’t seal out moisture or contaminants – it provides insulation and some mechanical toughness, but not waterproofing. The translucent nature of nylon insulation is handy because you can see if the wire is properly inserted and that the crimp engaged correctly. Nylon terminals cost a bit more, but they are preferred in automotive and marine applications where vibration is present, because that extra strain relief and toughness can prevent failures.

-

Heat Shrink Insulation (Adhesive-Lined): The premium option for insulation and sealing is the heat shrink connector. These terminals have a polyolefin heat-shrink tube as the insulation. After crimping the terminal onto the wire, you apply heat (with a heat gun or similar) to shrink the tubing. Heat shrink crimp connectors often have an adhesive lining that melts and flows during heating. As the tubing shrinks, this melted adhesive bonds to the wire insulation and the terminal, creating a waterproof seal around the connection. The result is a very robust, sealed connection that keeps out water, salt, and corrosion. Heat shrink terminals are ideal for any application exposed to moisture or corrosive environments – automotive engine bays, marine wiring on boats, outdoor lighting, etc. They effectively make the wire joint weatherproof. Additionally, the tubing provides good strain relief once shrunk. The trade-off is cost: heat shrink connectors are more expensive than vinyl or nylon, but for critical connections, the investment is worth it. In fact, in industries like trucking, heat shrink crimps are considered the best practice for reliable, long-lasting repairs.

-

Uninsulated Terminals (with Separate Insulation): Not a material type per se, but it’s worth noting: some connectors are sold uninsulated (just the bare metal). These are used typically for heavy-gauge cables (where built-in insulation won’t fit, or where you need to apply your own insulation). After crimping a bare terminal, you must insulate it to prevent shorts – commonly done by sliding a piece of heat shrink tubing over the connection and shrinking it, or using a silicone insulator cap. Uninsulated lugs for large wires (like a 4 AWG battery cable lug) are crimped with a heavy-duty crimper and then covered with heat shrink. This gives a result similar to a heat shrink connector, though the adhesive may not be present unless you use special glue-lined heat shrink tubing.

In summary, choosing the right insulation comes down to the environment and longevity required. For dry, controlled environments, basic vinyl-insulated crimps are fine. For moderate stress or temp, nylon-insulated connectors add durability. And for any situation where moisture, corrosion, or heavy vibration is expected, heat shrink insulated terminals are the gold standard, keeping your connection safe from the elementsi. Remember, even the best terminal needs a proper crimp – always use a good crimping tool to compress the connector fully, and give the finished crimp a gentle pull test. A well-crimped, well-insulated connection will last for years.

👉Dependable crimp terminals tools—Haisstronica for heat‑shrink ends.

Conclusion

Understanding wire terminals and using them correctly is an essential skill for anyone working with electrical wiring – from car enthusiasts and electricians to hobbyist DIYers. We’ve learned that a wire not properly terminated can cause unreliable performance or even hazards, whereas using the right crimp connector and crimping it correctly yields a safe, dependable connection. By selecting the appropriate terminal type for the job – be it a ring terminal for a solid ground connection or a butt splice to fix a broken wire – you ensure your wiring is both electrically sound and mechanically robust. We also covered insulation options, emphasizing that for maximum durability (especially against moisture), heat shrink sealed crimps are the way to go.

As you apply this knowledge, always remember the core tips: match your terminal to the wire size, use a quality wire crimping tool (avoid the temptation to just mash with pliers), and inspect each crimped connection for tightness. Good crimping technique will save you time and prevent failures – a few extra seconds to do it right is worth it for peace of mind. If you’re new to crimping, practice on some scrap wires and connectors to get a feel for how a proper crimp looks and feels. And if you ever find yourself without a crimper, know that there are alternative connectors (like twist-on wire nuts or tap connectors) – but these are generally less secure than a true crimp. It’s always best to use the proper tool; even an affordable crimping tool kit will dramatically improve the quality of your wiring work.

In the end, mastering the use of wire terminals (and making perfect crimps) will make your electrical projects safer and more reliable. Whether you’re wiring a car, a boat, or a home DIY project, you can now confidently choose the right connector and install it correctly. As a final note, having dependable tools and components is half the battle – consider investing in high-grade terminals and a ratcheting wire crimper for the best results. Haisstronica is proud to offer both premium connectors and the crimp tools to install them, so you can tackle any wiring task like a pro. Happy crimping, and may all your connections be secure!

Our Top User-friendly Picks

Get gas‑tight joints with Haisstronica’s ratcheting action: dense compression, no hot spots, and reliable sealing when used with heat‑shrink copper crimp connectors. Pair with marine‑grade, waterproof crimp connectors for corrosion resistance, then verify pull strength on your copper wire crimps. Professional finishes in minutes.

👉A compact ratchet crimp tool—Haisstronica for AWG 22–10.

References: