When it comes to making secure electrical connections, using the right crimping tool is essential. Crimping wires to terminals creates a permanent bond by deforming a metal connector around the wire strands – essentially forming a cold-welded and gas-tight electrical connection. But not all wire crimpers are equal. From basic crimping pliers to advanced hydraulic crimpers, each type serves a different purpose. So, which type of crimper is best? The answer depends on your specific application – the wire size, connector style, and quality requirements all influence the choice of crimping tool. In this comprehensive overview, we’ll explore the main types of crimpers and their uses, examine various crimp die profiles (hex vs. indent and more), and discuss what defines the “best” crimping tool in terms of performance metrics and industry standards. By the end, you’ll know how to select the optimal crimp tool for your needs – and why investing in a quality tool (like those from Haisstronica) ensures every crimp is safe and reliable. Don’t settle for subpar connections – upgrade to Haisstronica’s high-performance crimping tools and crimp connectors right the first time for a secure, long-lasting electrical connection.

Crimping Tool Types Overview (Manual, Ratcheting, Hydraulic & More)

An electrician uses a ratcheting wire crimping tool to secure a connection in a breaker panel. Choosing the correct crimping tool type (manual vs ratchet vs hydraulic) is crucial for achieving consistent, safe crimps on different wire gauges. High-quality tools like Haisstronica’s ratcheting crimpers make the job easier and more reliable.

There are many types of crimping tools available, each suited to different tasks and wire sizes. At the most basic level are manual crimpers, often resembling simple pliers. These require hand pressure to crimp a connector and are typically used for light-duty jobs or quick repairs. While inexpensive and portable, non-ratcheting crimping pliers rely on user feel – it’s easy to under-crimp or over-crimp with plain pliers. In fact, crimping with pliers or using the wrong tool is a common mistake that can result in a weak connection or damaged connector. A step up in both quality and ease-of-use is the ratcheting crimper tool. Ratcheting crimpers have an internal mechanism that won’t release until the crimp is fully compressed, ensuring consistent pressure on every crimp. This design prevents partially done crimps and gives more uniform results, which is why ratchet wire crimper tools are popular among electricians and professionals. For example, a dedicated butt connector crimper with a ratchet action makes it easy to crimp insulated butt splices evenly without worrying about slippage or uneven pressure. When you use a Haisstronica ratcheting wire crimper, you get a perfect crimp every time – a level of consistency no ordinary plier can match, making it a must-have electrical crimping tool for wiring projects.

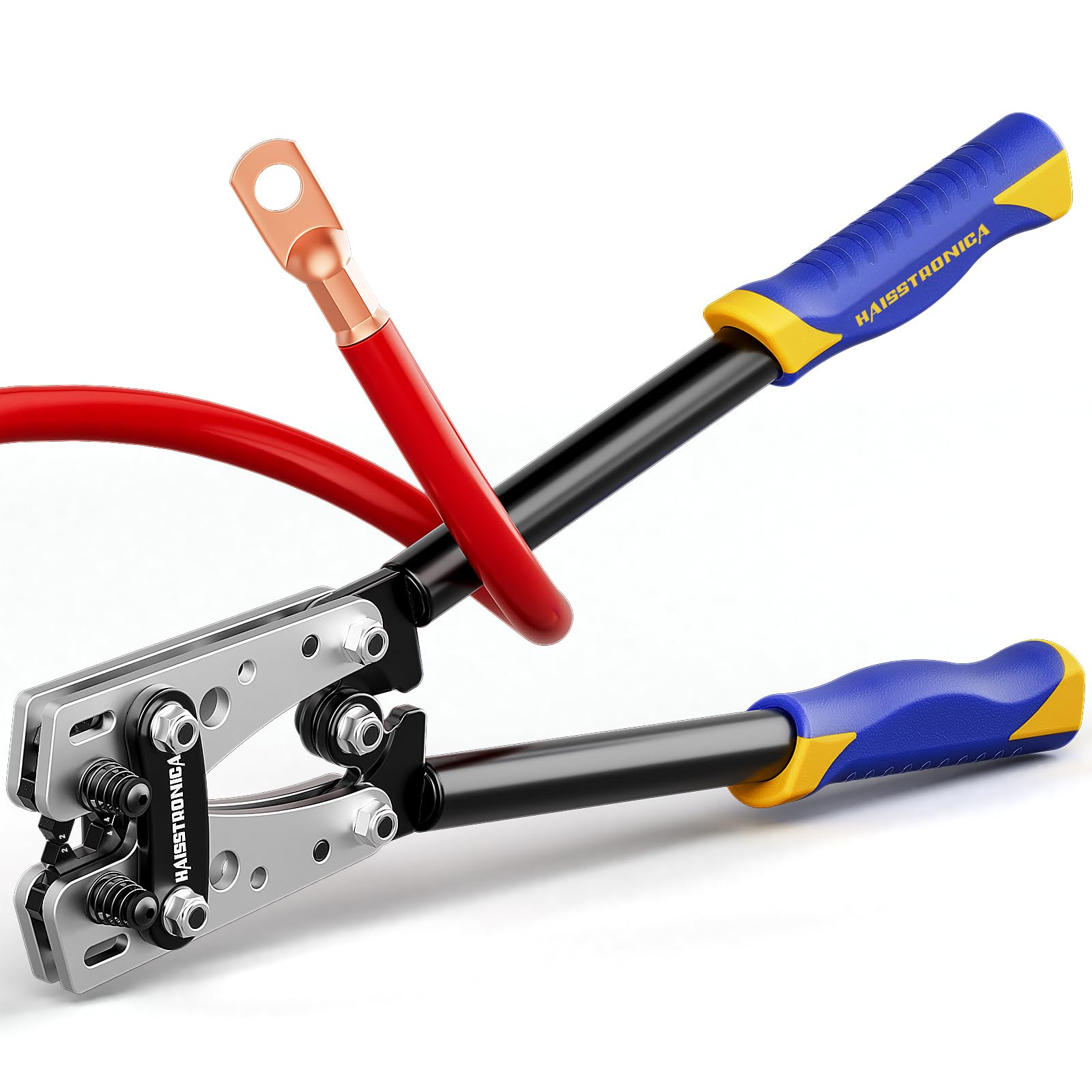

For heavier cables and lugs, manual force may not be sufficient. This is where heavy-duty crimping tools come into play. Hydraulic crimpers (hand-pump or battery-powered) generate much higher compressive force to handle large gauge wires (such as 4 AWG, 2 AWG, 1/0 gauge and beyond) and thick terminal lugs. These tools often use interchangeable dies for different cable sizes, or in the case of dieless crimpers, a self-adjusting indent mechanism. Hydraulic crimpers can apply tons of force with minimal effort, making them ideal for crimping heavy battery cables, welding leads, or utility cables that a handheld crimper cannot tackle. For instance, an automotive technician installing a 2/0 AWG battery cable will likely use a hydraulic cable crimper to ensure the lug is crimped securely – a standard wire crimping tool simply can’t accommodate such large conductors. Some heavy-duty lug crimpers are manual hydraulic pumps, while others are battery-operated electric crimping tools that allow one-handed operation and even higher efficiency. In industrial settings or high-volume production, pneumatic or automated crimping machines might be used to speed up the process and maintain precision. In general, the crimpers for wire you choose should match both the scale of your project and the connector types involved: small terminal crimpers for fine wires, robust hydraulic units for large lugs, and even all-in-one automatic crimping tools for assembly line efficiency. Whether you’re an electrician tackling a panel installation or a DIY enthusiast wiring a car stereo, Haisstronica has the right crimping tool for wires of any size – from handy ratchet crimpers for standard terminals to heavy-duty hydraulic crimpers for oversized cables, all engineered for professional-grade results.

It’s also worth mentioning specialty crimpers for particular connector styles. For example, open-barrel crimpers (sometimes called terminal crimp pliers) are used for the U-shaped terminals commonly found in automotive and electronics (like D-sub pins or Dupont connector crimping in PCBs). These tools create a B-crimp or F-crimp that wraps the terminal “wings” around the wire and insulation. There are also ferrule crimpers designed to square-crimp or hex-crimp ferrule connectors for finely stranded wires, coax cable crimpers for RF connectors, and modular plug crimpers for Ethernet cables (RJ45) – each type of crimper is optimized for a specific category of connector. The focus of this article, however, is mainly on crimpers for general electrical wiring: those used to attach lugs, splices, and terminals to copper electrical conductors. In summary, no single crimp tool is “best” for all purposes – instead, you should pick the best wire crimp tool for your particular connector and wire size. A high-quality ratcheting crimper might be the best choice for insulated terminals in an auto wiring harness, but a hydraulic hex crimper is the best option when installing a heavy-duty battery lug. Ultimately, understanding the differences in crimping tools electrical will help you make the right choice. Haisstronica’s product lineup includes everything from versatile ratcheting crimping tools for everyday use to specialized tools for unique connectors, so you’ll always have the best crimping tool on hand for the job – and that means safer, stronger connections every time.

Crimping Tool Dies & Profiles (Hexagonal, Indent, etc.)

Just as important as the tool type is the crimp die profile – the shape in which the connector barrel is compressed. A quality crimp isn’t just about squeezing a connector; it must be done in the correct geometry to properly cold-form the metal around the wire. Crimp dies come in various profiles (hexagonal, indent, oval, square, B-crimp, etc.), and using the right shape for the connector is critical for a reliable result. The hex crimp (hexagonal profile) is the most common type of crimp for copper and aluminum cables, lugs, and connectors in power applications. A hexagonal crimp die presses the connector barrel equally from six sides, applying central force uniformly around the circumference. This creates a solid crimp with strong mechanical strength and even compression of all wire strands. In fact, a proper hex crimp deforms the strands into a homogenous mass with minimal air gaps, though standard hex dies are typically not fully gas-tight without additional measures. The big advantage is that hex profiles work for both copper and aluminum conductors in compression lugs, and they’re widely used up to medium and high-voltage cable terminations. Hex crimping is considered so effective for copper that it’s seen as the most effective method for crimping copper power connectors, providing a smooth and strong crimp with little risk of strand damage. For this reason, most heavy-duty lug crimping tools (whether manual or hydraulic) include hex dies for various sizes, and many cable lugs are even marked with die codes corresponding to the hex die they should be crimped with. Haisstronica’s heavy-duty crimpers come with precision hexagonal dies that ensure your cable lugs are crimped with even pressure all around – exactly what you need for maximum current flow and a rock-solid connection on high-current cables.

The indent crimp is another common profile, historically the oldest type used for electrical terminals. Indent crimping tools have a pointed or wedge-shaped die that indents the connector barrel, typically from one or two sides. Unlike the enclosing hex shape, an indent crimp compresses the connector with one or more concentrated “points” of force. Indent crimps are solely suitable for copper conductors (not aluminum) and are often found in control panels, switchgear, and other electrical installations up to about 1000V. They are especially useful for certain cable constructions: fine-stranded or highly flexible conductors can be reliably crimped with indent profiles, which tend to “lock” the strands together and prevent slip-out. In fact, indent crimps (including the W-crimp profile for smaller gauges and a single indent for larger gauges) are often recommended for very fine strand classes (like those in welding cable or extra-flexible leads) because the indent penetrates and bundles the strands, creating a permanent connection. One downside is that indent crimps are not standardized by a universal code in the way hex crimps are, so quality control relies on using the matched tool and connector system from a reputable manufacturer. It’s imperative to use high-quality materials and tools for indent crimps to ensure a secure result. When done correctly (usually with a calibrated tool and the specified indent die for the lug), an indent crimp can be very strong and even approach a gas-tight seal. Indent crimpers are often dieless crimping tools – meaning they have a self-adjusting indent mechanism that can work across a range of sizes without swapping dies. A dieless crimper offers convenience (no separate dies to keep track of) and can adapt to slight variations in connector or wire dimensions. For example, if you have lugs from different manufacturers with slightly different wall thicknesses, a dieless indent crimper can adjust to form a solid crimp without the need for an exact die match. This flexibility makes indent/dieless crimpers popular for general field work or maintenance where you might encounter various connectors. However, the operator must take care to fully compress to the right point – unlike a fixed die, an indent crimp tool could under-crimp or over-crimp if used incorrectly, since there isn’t a hard die stop. Some dieless hydraulic crimpers have indicators or controlled pressure systems to help with this. If you prefer the versatility of a dieless indent crimper, Haisstronica has you covered with robust tools that deliver reliable crimps across multiple sizes – no need to fumble with die changes, and you’ll still achieve a tight, secure crimp on every connector.

In addition to hex and indent, there are other crimp profiles worth knowing. Square crimp or four-indent (often used for wire ferrules or certain multi-pin connectors) compresses the barrel into a square shape, which can be useful for fitting into terminal blocks or screw clamps. Oval or double-O crimp is common for insulated terminals using certain hand crimpers, resulting in a flattened oval crimp that grasps the wire. There’s also the B-crimp or F-crimp used in open-barrel connectors, where one die bends the terminal tabs inward and another supports the underside, forming a tight wrap around the wire (and a second crimp on the insulation for strain relief). Regardless of the shape, the goal is the same: deform the connector barrel around the conductor to achieve a solid mechanical and electrical union. The best crimp profile is usually the one the connector was designed for – reputable connector manufacturers will specify whether a terminal needs a hex crimp, an indent, a band-clamp, etc. For example, aluminum cable lugs often require indent crimps to break through the oxide layer on aluminum strands, whereas most copper lugs are optimized for hex crimps. Using the wrong profile can result in a crimp that either doesn’t hold (too loose) or one that damages the connector/wire (too tight or wrong form). Always match your crimping tool and die to the connector type and size – many lugs are stamped with die index numbers or color codes to guide you. Modern ratcheting crimpers usually have multiple die nests (for different gauges) that create the correct profile for insulated terminals, etc., and hydraulic crimpers come with die sets color-coded or numbered per cable size for hex crimps. Haisstronica’s crimping tools and connector kits are designed as systems – our dies and crimp connectors are perfectly matched, taking the guesswork out of choosing the right crimp profile. The result? Every crimp you make is secure, professional, and meets the recommended specifications for that connector type, giving you peace of mind and saving you from costly rework.

How to Define the “Best” Crimping Tool (Quality Metrics & Standards)

We’ve discussed types of crimpers and die profiles – now let’s address what makes one crimp tool “better” than another. In evaluating crimping tools, the primary consideration is the quality of the crimp connection they produce. A good crimp tool should consistently create crimps that meet or exceed industry standards for mechanical strength, electrical conductivity, and durability. From a quantitative standpoint, one key metric is tensile pull-out force: how much force the crimped wire can withstand before it pulls out of the connector. Standards like UL 486A/B specify minimum pull-out forces for different wire gauges (for example, a #18 AWG crimp must hold around 20 lbf, and larger wires correspondingly higher forces). A top-quality crimp tool, used with the correct connector, will produce crimps that easily pass these pull tests – meaning your wire won’t yank out under strain. Another important metric is electrical resistance through the crimped joint. A proper crimp essentially fuses the wire and connector barrel together, yielding a very low-resistance connection (practically as good as continuous wire) due to the large contact area and the elimination of air gaps (a process sometimes called creating a “gas-tight” joint). In fact, a perfect crimp is often described as forming a gas-tight bond that prevents oxidation and corrosion from developing inside the joint. If a crimp tool does not apply enough pressure, the result may be a loose crimp with voids, leading to higher resistance and a hotspot under load. Too much pressure (over-crimping) can crack the connector or sever wire strands, also weakening the connection. The best crimping tools apply just the right amount of force and have the right die/profile to achieve optimal compression. This is why ratcheting mechanisms and calibrated dies are valued – they enhance consistency and repeatability, which is crucial for meeting specifications every time. Many professional crimp tools are UL-listed or certified for use with specific connectors, meaning they’ve been tested to produce compliant crimps when used as directed. For example, certain ratchet crimping tools are UL-classified for particular insulated terminals – using those tools and connectors together yields a UL approved connection that you can trust in electrical installations. When you choose a Haisstronica crimping tool, you’re getting a device engineered for performance and reliability – our tools are designed to compress connectors to the exact degree needed for a secure, low-resistance crimp, taking the guesswork out of meeting industry standards.

Beyond the crimp itself, other factors define a great crimping tool. Durability and build quality matter, because a tool that maintains accurate jaw alignment and consistent pressure over thousands of cycles is vital for professionals (nobody wants a tool that loosens up and starts making poor crimps after a few uses). High-grade steel dies, corrosion-resistant finishes, and solid hinge or hydraulic components contribute to longevity. Ergonomics and ease-of-use are also important – comfortable handles, manageable trigger force, or hydraulic assist can reduce fatigue if you’re crimping many wires. The best tools often have convenient features like quick-change dies (for versatility), integrated wire cutters/strippers (for efficiency), or adjustable crimp force (to fine-tune for various connectors). For instance, some ratcheting crimpers allow you to calibrate the tightness via a dial, ensuring you don’t over-compress delicate terminals. Another hallmark of a top-tier crimp tool is precision: the die cavities should be machined to exacting dimensions so that each crimp is uniformly compressed. Precision tooling ensures that electrical connectors crimp correctly every time, which is especially critical for components like aerospace or automotive wiring where reliability is paramount. In professional settings, crimp quality might even be verified by inspecting crimp cross-sections under a microscope or performing periodic pull tests – a high-quality crimp tool will consistently pass these tests, whereas a subpar tool may produce more variability. Industry standards and certifications (like MIL-T-7928 for military crimps or IPC/WHMA-A-620 for cable harnesses) exist to guide what a good crimp looks like, often including criteria for crimp height, width, and the absence of cracks or wire strand breakage. The “best” crimping tool for a given job is one that enables you to meet these criteria with ease. Haisstronica understands these quality metrics deeply – that’s why our electrical crimping tools are crafted to deliver precise, repeatable results that align with industry standards. When you use a Haisstronica tool, you can trust that your crimp connections will be mechanically strong (meeting pull-test requirements) and electrically sound (low resistance and vibration-resistant) for a professional-grade outcome.

Finally, safety and reliability are the ultimate measures of any crimping solution. A proper crimp made with a good tool will not fail under normal operating conditions – it will not come loose, heat up excessively, or corrode prematurely. This reliability is especially crucial in high-stakes applications like automotive brake controllers, aircraft wiring, or mains electrical connections in a home. Poor crimps (often caused by using the wrong or inferior tool) can lead to dangerous failures such as wires pulling out (causing open circuits or sparks) or overheating (leading to melted insulation or fires). Thus, investing in the best crimping tool is also an investment in safety. The cost of a quality crimper tool is small compared to the potential damage from an electrical failure. Moreover, using a well-designed tool can significantly improve your work efficiency and confidence. You’ll spend less time re-crimping or troubleshooting bad connections and more time getting the project done right. So how do you know a crimp tool is delivering the best results? Look for evidence: smoothly crimped barrels with clearly imprinted die codes or markings (if applicable), no play or wiggle of the wire in the connector, and successful testing (tug firmly on the crimp – it should hold tight, and measure the voltage drop – it should be negligible). If these boxes are checked, your tool is doing its job. It’s also wise to periodically inspect and calibrate tools if you use them heavily; even the best tool benefits from basic maintenance (cleaning, occasional adjustment). In summary, the best crimping tool is one that matches your connector and wire, is built to high standards, and consistently produces crimps that meet the rigorous demands of real-world use. Haisstronica’s crimping tools excel in all these aspects – from rugged build quality and ergonomic design to precision-engineered dies – ensuring that every crimp you make is of top quality. When you use Haisstronica wire crimpers tools, you’re not just buying a tool, you’re gaining peace of mind that your electrical connections will perform flawlessly for years to come.

Conclusion: In the quest to find which type of crimper is best, it ultimately comes down to using the right tool for the right job and prioritizing quality. A manual crimping tool might be best for a quick fix or smaller gauges, a ratcheting crimper is best for consistent crimps on standard electrical connectors, and a hydraulic hex crimper is best for large lugs – but across all these, the common theme is that the tool should produce a secure, standard-compliant crimp connection. By understanding the differences in crimping tool types and die profiles, and by considering the key performance metrics (tensile strength, electrical continuity, etc.), you can make an informed choice and select the best crimping tool for your needs. Remember that even the finest tool must be paired with the correct connectors and used properly to realize its full benefit. When in doubt, consult the connector manufacturer’s recommendations and follow industry guidelines for crimping. With a reliable tool in hand, you’ll have confidence that every crimp you make – whether it’s a tiny ferrule or a massive cable lug – will be safe, strong, and durable. And if you’re looking to upgrade your toolkit, consider Haisstronica’s range of professional crimpers and connector solutions. Haisstronica has built its reputation on providing electricians and DIY enthusiasts with the best wire crimping tools for every application, backed by industry expertise and a commitment to quality. By choosing the right crimper and using it correctly, you’ll ensure your wiring projects are built to last. Don’t compromise on your connections – equip yourself with a top-notch Haisstronica crimping tool and crimp with confidence every time!

References: