Wire crimping is a fundamental skill in electrical work, whether you’re installing wiring harnesses, repairing vehicles, or building IoT devices. However, even minor mistakes during the crimping process can compromise safety, reliability, and efficiency. In this guide, we’ll uncover the 5 most common crimping mistakes and provide actionable solutions to ensure flawless connections every time.

1. Using the Wrong Connector Size

Mistake: Choosing a connector that doesn’t match the wire gauge.

Why It’s Bad: Undersized connectors crush the wire, causing resistance and overheating. Oversized connectors leave gaps, increasing the risk of corrosion and arcing.

How to Fix:

Always check the AWG (American Wire Gauge) rating on both the wire and connector.

Use a self adjusting wire stripping tool to ensure clean, precise cuts (avoid nicked wires).

For industrial-grade jobs, invest in color-coded organizers (like HAISSTRONICA’s 3-bin system) to avoid mix-ups.

2. Skipping Proper Wire Preparation

Mistake: Skipping steps like stripping insulation or tinning copper wires.

Why It’s Bad: Dirty, frayed, or unprepared wires create weak bonds, leading to intermittent connections.

How to Fix:

Strip insulation using a high-quality wire stripping tool (HAISSTRONICA’s crimper includes a built-in stripper).

“Tin” stranded wires with solder before crimping for added strength.

Remove contaminants (oil, dirt) with isopropyl alcohol.

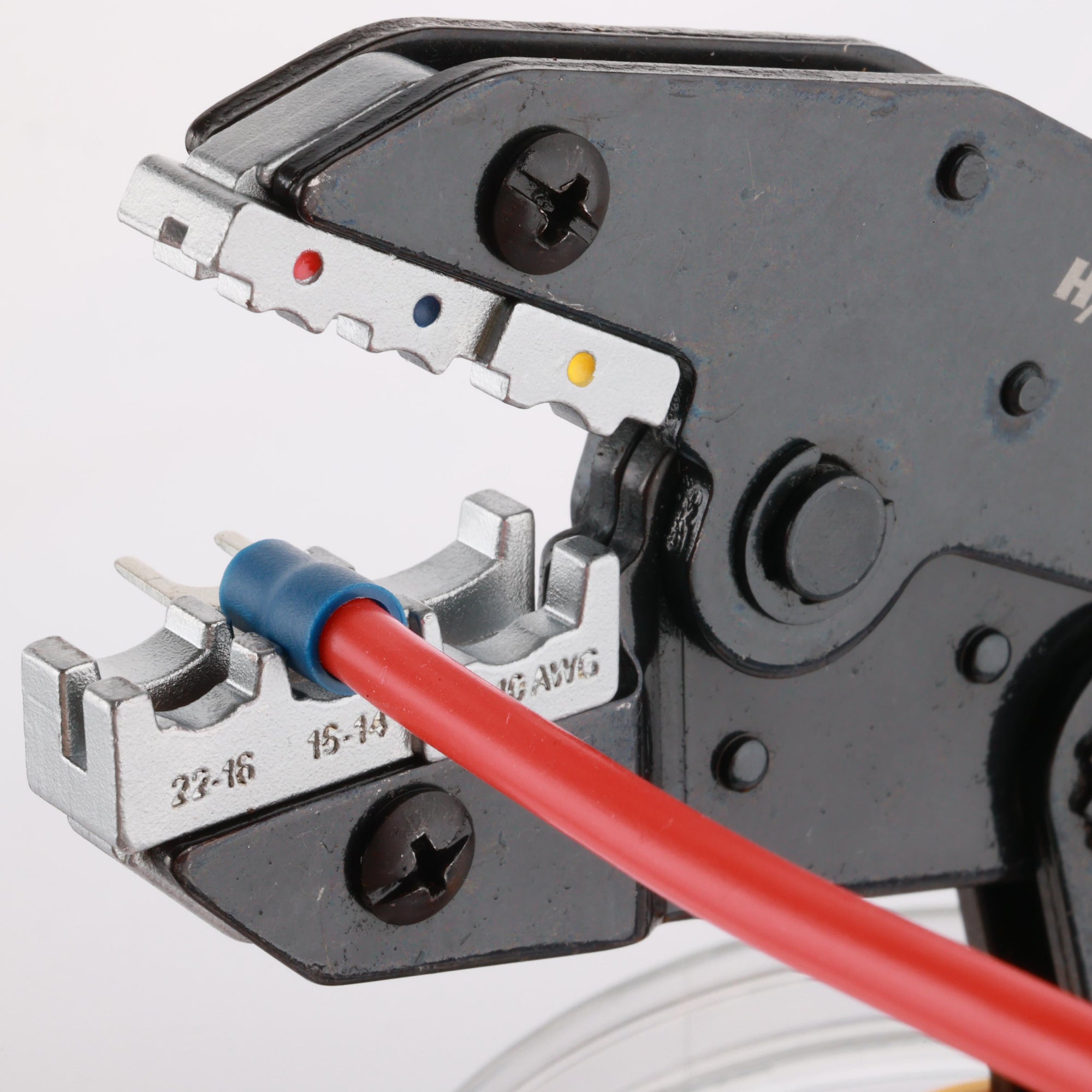

3. Over-Crimping or Under-Crimping

Mistake: Applying too much or too little force when crimping.

Why It’s Bad: Over-crimping damages the wire strands or connector; under-crimping leaves gaps.

How to Fix:

Use a ratcheting crimping tool with preset pressure points (HAISSTRONICA’s tool ensures uniform compression).

Test crimps with a pull-test tool to verify strength.

Avoid manual pliers, which lack precision.

4. Ignoring Environmental Factors

Mistake: Using PVC connectors in wet environments or failing to seal outdoor connections.

Why It’s Bad: Moisture causes corrosion, short circuits, and safety risks.

How to Fix:

Opt for heat-shrink tubing with waterproof adhesive (HAISSTRONICA’s kits include 380pcs).

Seal connectors with silicone gel or marine-grade tape for outdoor use.

Avoid aluminum connectors in high-vibration applications (copper is more durable).

5. Poor Storage Practices

Mistake: Throwing connectors into a messy toolbox.

Why It’s Bad: Damaged or mixed connectors reduce reliability and waste time.

How to Fix:

Use a portable organizer with labeled compartments (HAISSTRONICA’s 3-detachable bins are patented for organization).

Store connectors in a cool, dry place away from UV light.

Regularly inspect for signs of wear (e.g., cracks, discoloration).

Conclusion: Tools Make the Difference

Avoiding these mistakes starts with investing in quality tools and materials.

HAISSTRONICA’s Complete Crimping Kit combines:

330/380pcs heat-shrink/wire connectors

Ratcheting crimper with ergonomic grip

Portable organizer for hassle-free storage

Pro Tip: Subscribe to HAISSTRONICA for 5% off your first order and stay updated on industry trends.

Ready to upgrade your crimping game? Shop the HAISSTRONICA Crimping Kit today (free shipping on orders $35+) and join the community of pros who demand perfection. 🚀