Why “Butt Connectors with Solder” Is a Confusing Phrase

Modern heat shrink butt connectors with solder inside (silver rings) combine soldering and insulating in one step. The colored bands at the ends are adhesive that melts to seal wire insulation, making these electrical connectors waterproof for marine or automotive use.

If you’ve browsed online stores or forums for wiring supplies, you may have seen the phrase “butt connectors with solder.” At first glance, it’s a head-scratcher. Traditionally, a butt splice connector is a solderless wire connector – a crimped metal tube used to join two wires by mechanical force. In fact, in many wiring standards, butt connectors are explicitly considered an alternative to soldering (for example, automotive manufacturers specify crimped wire connections with heat shrink for reliability). So when a seller advertises butt connectors “with solder,” it sounds like a contradiction. Are we supposed to crimp the connector and also solder it? Or is it a completely different type of connector? This confusing wording leaves many DIYers and electricians puzzled. (Using a butt connector normally doesn’t involve a soldering iron at all – it’s meant to make electrical connections without solder.)

Part of the confusion is just phrasing. The seller is likely trying to describe a relatively new kind of wire connector that’s become popular in recent years – but doing so in an unclear way. The result is a mix of terminology that can mislead buyers. In some cases, people might think “butt connectors with solder” means you get a regular butt connector and then you’re expected to add solder to it manually. Others might recall debates about whether to crimp and solder a joint, and wonder if these products require doing both. No wonder it’s confusing!

To clarify, we’ll break down what sellers really mean when they use this phrase. In most cases, they’re talking about a special product where the soldering is built into the connector itself – but they might also be referring to a couple of other things. Let’s explore the three things “butt connectors with solder” might refer to (and how to tell which is which). By understanding the term, you can choose the right solution for splicing wires and avoid a shopping mistake. And remember – using quality connectors from a trusted brand like Haisstronica can save you headaches by ensuring you get exactly what you need for a safe, durable wire connection.

Three Things Sellers Might Mean by “Butt Connectors with Solder”

When a product is labeled as a butt connector with solder, it usually falls into one of three categories. Knowing these will help you decode product listings and pick the right item for your project (and avoid any unwelcome surprises). Here are the three possibilities:

1. Crimp-and-Solder Combination Connectors: In some cases, a seller might be referring to connectors that can be both crimped and then soldered for extra security. These typically look like regular insulated butt connectors (often also heat-shrinkable), but they’re designed so you can crimp them onto the wires and then heat them to melt solder that’s built-in or added. For instance, some products are marketed as “Crimp, Solder and Seal butt connectors,” meaning you crimp first, then apply heat to melt a preloaded solder ring, and finally the tubing shrinks to seal it. The idea is to combine the mechanical strength of a crimp with the electrical bonding of solder – essentially a belt-and-suspenders approach to electrical connections. These aren’t as common as type 1 above, but they do exist. If you see a listing for an “automotive wire connectors kit” or “sealed crimp connectors” that mentions solder, check if the instructions say to use a crimper and heat. The product description might use phrases like “crimp and seal connectors” or “solder crimp connectors.”

2. Misused Term or DIY Soldered Splices: Sometimes the phrase is simply used incorrectly or in a very general sense. A seller might say “butt connectors with solder” just to indicate their connectors make a connection “as good as solder,” or that you solder the wires together when using them. For example, we’ve seen people refer to an ordinary butt splice that they soldered the wire into as a “solder butt connector.” In practice, this might involve taking a plain metal butt connector (the kind without insulation), inserting the wires, crimping lightly or not at all, and then heating with a torch to flow solder through a hole or end of the connector. This isn’t a standard method for most electricians, but some old-school mechanics do it for certain high-current cables – effectively turning a crimp connector into a solder-on terminal.

Inside the Connector: What the Solder Does (and Doesn’t Do)

So, if you do have the actual solder seal butt connectors, what exactly is happening inside them when you apply heat? Let’s lift the hood on this wire connector technology. Inside the transparent heat shrink tube, there’s that ring of low-temperature solder. When you heat the connector, a few things happen in sequence: first the tubing shrinks tight onto the wire insulation, then adhesive rings at the ends melt and seal around the insulation, and finally the solder in the middle melts and flows into the exposed wire strands. The solder literally “wicks” into the wires, coating and bonding all the stripped conductors together. Once it cools, you have metallurgically joined the wires – essentially as if you hand-soldered them, except it was done by the connector itself. This provides a low-resistance electrical connection (good conductivity) because the wires are bonded with solder throughout the joint. It also means the splice can be very strong in tension – a properly melted solder joint won’t pull apart easily. In fact, one advantage noted by users is that these solder wire splices often can’t be pulled apart by hand when done correctly. The solder forms a solid bridge that holds the wires together inside the sleeve. Additionally, because the outer tubing has shrunk and the hot-melt glue has gripped the insulation, the finished joint is sealed from water and strain-relieved against vibration. This is why good solder seal connectors are often advertised as “waterproof marine electrical connectors.” They keep moisture out and stand up to moderate movement or vibration (common in automotive or boat wiring). As one industry article put it, solder seal connectors create a connection that is not only electrically solid but also waterproof and resistant to being pulled apart. That’s a big win when repairing wires in tough environments.

However, it’s important to understand what the solder in these connectors doesn’t do, so you have realistic expectations. First, the solder alone does not make the connection infallible if the joint is not heated properly. You must heat these connectors thoroughly until you see the solder fully melt and flow; if you underheat it, you could get a “cold” solder joint that is weak. So take the time to do it right (a heat gun is best for even heating). Second, the solder doesn’t negate the need for support. In a soldered joint, the soldered portion of the wire becomes solid (no longer flexible strands), which can be a point prone to break if the wire is flexed repeatedly right at that spot. In crimped joints, the wire strands can still flex a bit inside the crimp; in a soldered joint, they’re frozen in solder. For this reason, solder-only connections can crack under constant vibration if not strain-relieved. The good news is that the heat shrink tubing in these connectors does act as a built-in strain relief – it holds the wires and reduces flex at the junction. But it’s still wise not to use solder connectors in places that experience extreme continuous movement or heavy vibration (for example, a wire constantly bending on a moving engine part). In those cases, a crimped connector might be more forgiving. Many professionals recommend using solder seal connectors for general automotive or marine wiring repairs (lighting circuits, speakers, sensors, etc.) but sticking to crimped terminals for critical high-vibration connections.

Another thing to note: the solder used in these connectors is a special low-temperature alloy, often with a melting point around 138°C (280°F). That’s how you’re able to melt it with a heat gun relatively quickly. This solder is plenty strong for the connection, but if your wiring ever gets hotter than 138°C, the solder could theoretically re-melt. In practice, that’s rarely an issue – if your wires are that hot, you likely have a bigger problem in the circuit! As one guide points out, above the solder’s melting point (~138°C) the joint could re-melt, but if your wiring is getting that hot, you have other problems. Just make sure you use the right gauge wire and connector for the current you’re carrying (don’t put a tiny connector on a big wire that draws high amperage). Also, avoid using these solder connectors super close to engine exhausts or other extreme heat sources. For most automotive and electrical applications, they handle the temperatures just fine and the solder won’t soften under normal conditions.

Lastly, the solder inside these connectors doesn’t mean you can join an unlimited number of wires or massively different sizes with one connector. While the solder will bond wires even if you have more than two in the splice, you should still stick to the connector’s recommended wire bundle size. Technically, some solder seal connectors can join 3-4 thin wires together because the solder can flow into all of them. But overstuffing a connector can lead to a weak physical hold or incomplete solder flow. It’s best to use one connector per two wires (one on each end) for optimal strength – or use a proper distribution block if you need to split off multiple connections. The solder also doesn’t “upgrade” the amp rating of the connector; a small connector can only handle so much current-carrying cross-section. So use the correct color/size connector for the wires in question (red, blue, yellow, etc., corresponding to wire gauge ranges).

Conclusion

In summary, the phrase “butt connectors with solder” is a bit of a misnomer that has caused understandable confusion. What it really refers to is usually the handy heat shrink solder & seal connectors that have become popular for making quick, reliable splices without a separate soldering iron. Instead of crimping, you simply heat these connectors and the built-in solder splices the wires for you, giving you a strong bond and a fully insulated, sealed joint. We’ve also seen that some products combine crimping and soldering, and that sometimes the term is used (or misused) loosely. But the key takeaway is that if you see “with solder” in a butt connector description, odds are the seller is talking about those solder ring heat shrink connectors that simplify the whole process of soldering connections.

For DIYers and electricians, knowing this can help you choose the right connector. These solder connectors can save you time and frustration, especially in tight spaces or when you don’t have an iron handy – just a heat gun and you’re good to go. They’re waterproof connectors once shrunk, and they make for very neat, low-profile splices (no big bulky crimp barrel). That said, use them wisely: ensure you heat them thoroughly, use the correct size, and avoid situations beyond their design (extreme vibration or heat). When used appropriately, they offer the best of both worlds – the conductivity of a soldered joint and the protection of a sealed connector – all in one.

If you were wary because the term was confusing, you can rest assured that it’s not some strange new technique requiring special skills. It’s actually a user-friendly solution: “butt connectors with solder” = soldered butt splices made easy. Many hobbyists report excellent results, with one Popular Mechanics editor even saying after trying them he “doesn’t think he’ll ever use a crimping tool again”. That’s a strong vote of confidence in this technology. And when you get your connectors from a reliable source, you can trust the solder will melt at the right temp and the tubing won’t split or fail.

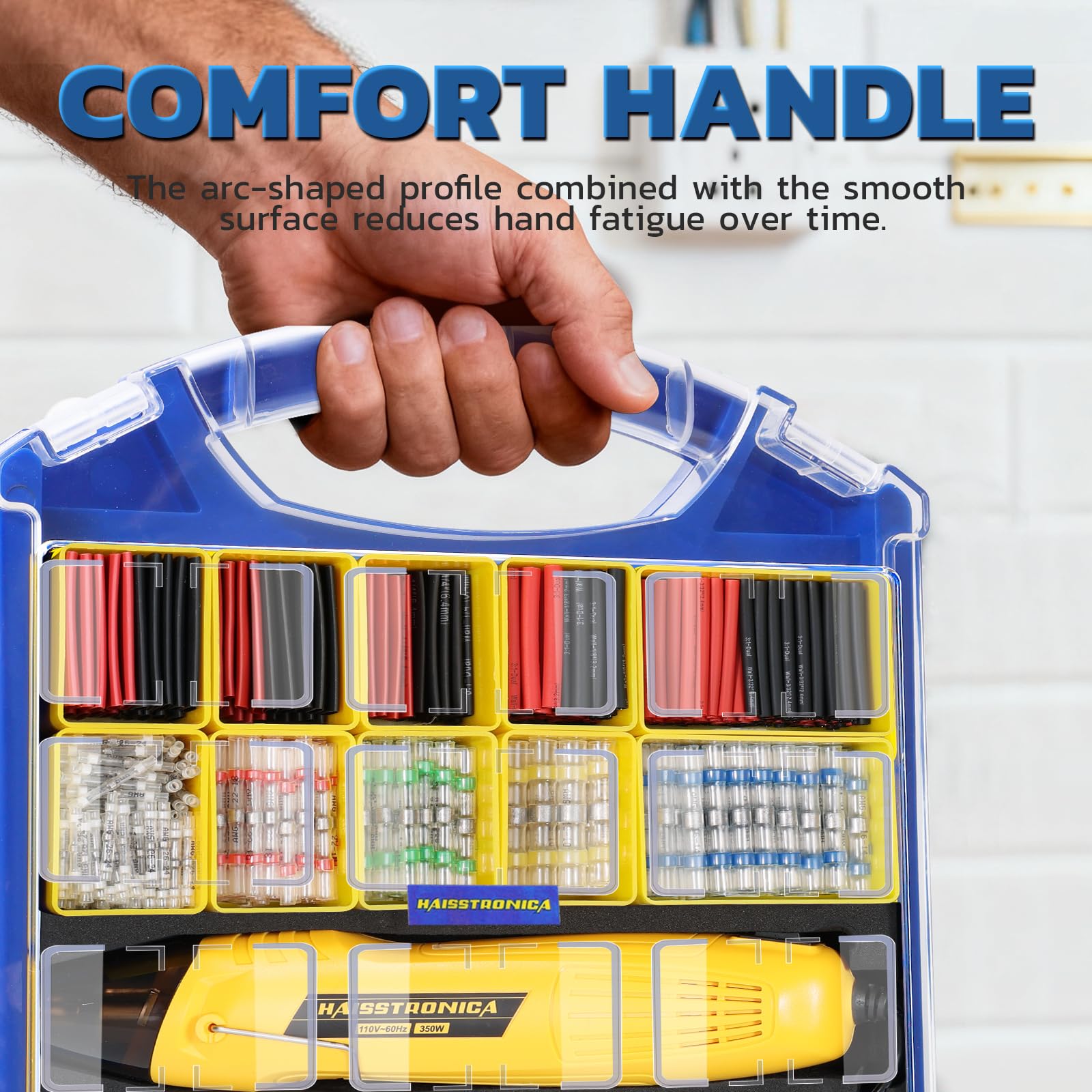

Speaking of reliable sources – if you’re looking to try these out, consider grabbing a set of Haisstronica solder seal butt connectors. Haisstronica is a brand known for high-quality electrical connectors (automotive grade) that are rigorously tested. Their solder connectors use pure copper crimp barrels and real adhesive-lined tubing that meets marine standards. With a wire connector kit from Haisstronica, you’ll have an assortment of sizes (red, blue, yellow, etc.) to cover all your needs, along with the peace of mind that each connector will perform as expected. In other words, you’ll make wire connections that last.

No more scratching your head at confusing product names – now you know what “butt connectors with solder” really means. It’s not an oxymoron, but rather a clever product that can make your next wiring repair or project easier and more efficient. So go ahead and confidently tackle those splicing wires tasks. With the right connectors and a bit of heat, you’ll have sealed, soldered connections that you can trust in your car, boat, or home electrical work. Happy soldering and happy crimping – whichever method fits the job, now you’re equipped to choose the right tool for the task. And if you choose solder seal connectors, enjoy the convenience of a well-engineered solution that truly connects wires with a simple heat shrink and solder process.