Introduction

Les connecteurs bout à bout offrent un moyen simple et efficace de raccorder des fils électriques bout à bout. Ils constituent l'une des méthodes d'épissure les plus courantes et les plus fiables, permettant de terminer un fil en toute sécurité ou de le prolonger en le connectant à un autre fil. En résumé, un connecteur bout à bout est un connecteur à sertir court et cylindrique qui fixe deux extrémités de fil ensemble à l'intérieur d'un tube métallique (le « bout »). En sertissant le connecteur, vous déformez le corps métallique autour des extrémités dénudées du fil, créant ainsi une liaison électrique solide. Ces connecteurs de cosses sont largement utilisés dans les câblages automobiles, marins et domestiques grâce à leur simplicité d'utilisation et à leur fiabilité. Dans cet article, nous aborderons la définition des connecteurs bout à bout, leur utilisation, leurs applications courantes, comment choisir le bon type et répondrons à quelques questions fréquentes. Nous vous présenterons également un kit de connecteurs bout à bout thermorétractables de haute qualité pour vos projets.

👉 Choisissez les connecteurs bout à bout thermorétractables à sertir électriques Haisstronica AWG 22-10 pour une épissure bout à bout fiable.

Définition : Qu'est-ce qu'un connecteur bout à bout exactement ?

Un connecteur bout à bout (parfois appelé épissure bout à bout ) est un type de connecteur électrique utilisé pour joindre deux fils en ligne droite (bout à bout) par sertissage. Le connecteur lui-même est un petit tube (généralement en métal comme le cuivre) avec une gaine extérieure isolée. Pour l'utiliser, insérez l'extrémité dénudée d'un fil de chaque côté du connecteur, puis sertissez le tube métallique pour maintenir les fils en place. Cela forme une connexion bout à bout sécurisée qui transporte le courant d'un fil à l'autre. Les connecteurs bout à bout sont également appelés connecteurs à sertir , épissures bout à bout ou cosses bout à bout, et il en existe différentes variétés : connecteurs bout à bout isolés en vinyle ou en nylon , connecteurs bout à bout thermorétractables et connecteurs bout à bout non isolés , entre autres. Le terme « connecteur bout à bout » (écrit en un seul mot) ou « connecteurs bout à bout » (mal orthographié) désigne la même chose : un connecteur reliant deux extrémités de fil. Essentiellement, les connecteurs bout à bout sont un sous-ensemble de connecteurs de fils et de bornes électriques conçus pour l'épissure en ligne.

Code couleur : La plupart des connecteurs électriques sont codés par couleur en fonction du calibre du fil afin de garantir l'utilisation du connecteur adapté. Par exemple, les connecteurs rouges conviennent généralement aux fils de calibre 22 à 16 AWG, les bleus aux fils de calibre 16 à 14 AWG et les jaunes aux fils de calibre 12 à 10 AWG. Ce code couleur permet d'identifier la capacité du connecteur d'un coup d'œil. Utiliser la bonne taille est essentiel pour un sertissage sûr : trop grande, le fil ne sera pas bien serti ; trop petite, il ne s'adaptera pas du tout. Les tailles de connecteurs bout à bout vont même au-delà des tailles courantes : certaines marques proposent des connecteurs bout à bout blancs pour les fils très fins (26–24 AWG) et des épissures bout à bout spéciales plus grandes pour les fils de gros calibre (8 AWG, 4 AWG, etc.). Dans tous les cas, veillez à toujours choisir le connecteur adapté à votre section de fil pour une connexion fiable.

👉 Obtenez des joints étanches et propres grâce aux connecteurs bout à bout thermorétractables à sertir électriques Haisstronica AWG 22-10 — parfaits pour les connecteurs d'épissure bout à bout.

Comment utiliser un connecteur bout à bout (étape par étape)

L'utilisation d'un connecteur bout à bout est simple, mais une technique appropriée garantira une épissure solide et durable. Que vous soyez débutant ou bricoleur expérimenté, ces étapes vous guideront pour réaliser correctement une épissure bout à bout . Examinons le processus typique d'utilisation d'un connecteur bout à bout thermorétractable (les étapes sont similaires à celles des connecteurs standard, sans chauffage) :

-

Préparez les fils : Assurez-vous que l'alimentation est coupée avant de commencer. Coupez les extrémités endommagées afin d'obtenir du cuivre propre. À l'aide d'une pince à dénuder, retirez environ 6 mm d'isolant à l'extrémité de chaque fil. Cette longueur doit correspondre à peu près à la profondeur du corps métallique du connecteur. Si le fil est multibrins, torsadez les brins ensemble pour éviter qu'ils ne s'effilochent. Cette préparation garantit une insertion complète du fil dans le corps du connecteur et un bon contact.

-

Insérez les fils dans le connecteur : Choisissez un connecteur bout à bout de taille adaptée à votre section de fil (vérifiez le code couleur ou les marquages sur le connecteur). Insérez une extrémité dénudée du fil dans un côté du connecteur jusqu'à ce qu'elle touche le fond au milieu. Insérez ensuite l'autre fil dans l'extrémité opposée. Dans un connecteur bout à bout thermorétractable transparent (qui possède souvent un manchon transparent), vous pouvez voir les deux extrémités en cuivre se toucher presque au centre du connecteur. Les deux extrémités du fil doivent être entièrement à l'intérieur du tube métallique et aucun fil de cuivre nu ne doit être exposé hors de l'isolant plastique. Si un brin dépasse, retirez le fil et retordez-le, ou dénudez un peu plus l'isolant si la partie exposée était trop courte pour atteindre le centre. Une insertion correcte est essentielle pour un bon résultat d'épissure bout à bout .

-

Sertissage du connecteur : À l'aide d'un outil de sertissage approprié (idéalement une pince à cliquet adaptée à la taille de votre connecteur), sertissez fermement le corps métallique sur chaque fil. Positionnez le connecteur dans la mâchoire appropriée de l'outil de sertissage (faites correspondre la couleur du connecteur à la matrice de l'outil, par exemple, utilisez la fente « rouge 22-16 AWG » pour un connecteur rouge). Serrez l'outil à fond ; une pince à cliquet ne se relâchera pas tant qu'une pression suffisante n'est pas appliquée, assurant un sertissage solide. Sertissez un côté de l'épissure bout à bout sur le premier fil, puis sertissez l'autre côté pour le second fil. Ne sertissez pas l'isolant plastique , mais uniquement la zone au-dessus du manchon métallique interne. Après le sertissage, tirez légèrement sur chaque fil pour vous assurer qu'il est bien serré et qu'il ne se détache pas. Un sertissage correct déforme le corps métallique du connecteur autour du fil, ce qui permet une connexion mécanique et électrique solide (souvent appelée sertissage bout à bout ). Conseil : N'utilisez pas de pince ordinaire ou de marteau pour sertir ; un sertissage uniforme et à haute pression à partir d'un outil approprié est essentiel pour la fiabilité Cela empêche une connexion lâche ou que le fil glisse hors du connecteur bout à bout .

-

Thermorétractable (le cas échéant) : Si vous utilisez des connecteurs bout à bout thermorétractables (également appelés connecteurs bout à bout thermorétractables ou connecteurs bout à bout marins ), l'étape finale consiste à sceller la connexion. Après le sertissage, appliquez de la chaleur à l'aide d'un pistolet thermique (ou d'un mini-chalumeau). Appliquez le pistolet thermique uniformément sur le connecteur. Le manchon extérieur du connecteur bout à bout thermorétractable commence à se rétracter autour du fil, et vous verrez généralement de la colle suinter légèrement aux extrémités. Cette couche adhésive interne fond et coule pour sceller la jonction , la rendant ainsi étanche . Continuez à chauffer jusqu'à ce que le tube soit complètement rétracté et que la colle ait scellé les bords. Laissez refroidir quelques secondes sans le toucher. Vous obtenez ainsi une connexion thermorétractable étanche , protégée de l'humidité et des vibrations. En résumé, l'isolant du connecteur forme désormais un manchon étanche autour de l'épissure, la protégeant de l'eau et des saletés. (Si vous utilisez un connecteur bout à bout standard en vinyle ou en nylon sans thermorétractable, vous pouvez ignorer cette étape de chauffage ; notez toutefois que ces connecteurs ne sont pas étanches sans précautions supplémentaires.)

-

Vérification de la connexion : Une fois refroidi (pour les connecteurs thermorétractables), inspectez l’épissure. Le tube doit être bien ajusté et sans jeu. S’il s’agit d’un connecteur translucide, vous pouvez vérifier visuellement que le fil est bien serti à l’intérieur. Effectuez un dernier essai de traction sur les fils. Si tout est bien fixé, l’épissure bout à bout est réussie. Vous pouvez maintenant rétablir le courant et tester le circuit. Une jonction électrique de connecteur bout à bout correctement sertie est aussi conductrice qu’un fil intact. Il est également conseillé de plier légèrement la connexion d’avant en arrière pour vous assurer qu’elle ne soit pas fragile (surtout pour les connecteurs à souder). Si toutes ces vérifications sont concluantes, votre épissure bout à bout est prête à fonctionner !

Scénarios d'application pour les connecteurs bout à bout

Grâce à leur fiabilité et à leur simplicité d'utilisation, les connecteurs bout à bout sont utilisés dans de nombreux secteurs et projets. Voici quelques exemples d'applications courantes :

-

Câblage automobile : Les connecteurs bout à bout sont largement utilisés dans les voitures, les camions et les motos pour la réparation ou l'installation de faisceaux de câbles, de systèmes audio, de câbles de remorque, etc. Ils permettent d'épisser des fils dans des espaces restreints (comme les tableaux de bord ou les compartiments moteur) sans connecteurs encombrants. Par exemple, les épissures bout à bout sont idéales pour réparer un fil cassé dans un feu arrière ou pour rallonger un fil afin d'installer de nouveaux phares. L'utilisation de connecteurs bout à bout thermorétractables est particulièrement avantageuse dans ce cas, car les fils automobiles peuvent être exposés à l'humidité et aux vibrations ; la gaine thermorétractable offre une solution de connecteur bout à bout sûre, résistante aux vibrations et étanche .

-

Électronique marine et bateau : Sur les bateaux, l'humidité est une préoccupation constante. C'est pourquoi les connecteurs bout à bout de qualité marine (thermorétractables avec revêtement adhésif) sont la solution idéale. Ces connecteurs bout à bout étanches permettent des épissures étanches pour les câbles de pompe de cale, les feux de navigation, les sondeurs ou tout autre appareil électronique marin. La gaine thermorétractable à revêtement adhésif empêche l'eau salée et l'humidité de corroder la connexion. Qu'il s'agisse de câbler un bateau hauturier ou un petit moteur de pêche à la traîne pour kayak, les connecteurs électriques thermorétractables sont parfaitement adaptés à l'environnement marin.

-

Électricité domestique et bricolage : Les connecteurs bout à bout sont pratiques pour les réparations et les projets de bricolage. Par exemple, si vous coupez accidentellement le cordon d'une lampe ou devez réparer un fil d'un appareil électroménager, un connecteur bout à bout vous permet de le reconnecter en toute sécurité. Ils sont également utiles pour les travaux d'aménagement intérieur et extérieur, comme le raccordement des fils d'éclairage paysager (souvent à l'aide de connecteurs thermorétractables pour une meilleure résistance à l'extérieur) ou la fixation des fils des vannes d'arrosage. Lors de la fabrication d'appareils électroniques ou de gadgets personnalisés, vous pouvez utiliser des épissures bout à bout pour raccorder des fils sans soudure, ce qui est particulièrement utile pour les projets de loisirs ou les prototypes de circuits qui pourraient nécessiter une déconnexion ou un recâblage ultérieur.

-

Tableaux électriques et industriels : Dans les environnements industriels ou les machines, les connecteurs bout à bout (souvent robustes) sont utilisés pour des réparations ou des modifications rapides du câblage. Les techniciens peuvent épisser une section de fil de remplacement à l'aide d'un connecteur bout à bout pour remettre rapidement l'équipement en service. Par exemple, dans les tableaux de commande ou les équipements d'usine, les connecteurs bout à bout isolés permettent de raccorder les fils proprement sans fer à souder. Dans les machines soumises à de fortes vibrations ou les installations de panneaux solaires , l'utilisation de connecteurs électriques thermorétractables garantit la sécurité des connexions sous contrainte et les protège de la poussière et de l'humidité. Même dans l'aérospatiale et l'aviation, les connecteurs bout à bout sont utilisés pour certaines réparations (bien que généralement soumises à des spécifications strictes).

-

Remorques et véhicules : Outre le câblage automobile, les connecteurs bout à bout sont également très populaires pour le câblage des remorques (remorques utilitaires, camping-cars, etc.). Les câbles d'éclairage ou de freins qui longent une remorque nécessitent souvent des réparations ou des rallonges, et les connecteurs bout à bout (thermorétractables) offrent une solution rapide et fiable. Ils sont bien plus sûrs que l'entrelacement de fils ou l'utilisation de ruban isolant. De même, pour le câblage des motos ou des VTT, où l'exposition aux intempéries est élevée, les connecteurs bout à bout thermorétractables maintiennent les connexions au sec.

En résumé, les connecteurs bout à bout sont utilisés partout où il est nécessaire de raccorder deux conducteurs de manière fiable, des cosses à anneau dans un coffret électrique aux fils délicats d'un laboratoire d'électronique. Ils allient praticité et durabilité, ce qui en fait un outil indispensable pour les électriciens, les mécaniciens et les bricoleurs.

👉 Construisez-le correctement avec les connecteurs bout à bout thermorétractables à sertir électriques Haisstronica AWG 22-10 pour connecteur d'épissure bout à bout.

Guide de sélection : choisir le bon connecteur bout à bout

Tous les connecteurs bout à bout ne se valent pas. Choisir le type et la taille adaptés à votre projet est crucial pour une connexion sûre et durable. Voici un guide pratique sur les points à prendre en compte lors de l'achat de connecteurs bout à bout :

-

Compatibilité des calibres de fils : Choisissez toujours le connecteur adapté à la section de votre fil. Les connecteurs bout à bout sont vendus dans des tailles correspondant aux calibres de fils (souvent indiqués par une couleur, comme indiqué précédemment). Par exemple, utilisez un connecteur bout à bout rouge pour les fils de calibre 22 à 16 AWG, bleu pour les fils de calibre 16 à 14 AWG, jaune pour les fils de calibre 12 à 10 AWG, etc. Si vous avez des fils très gros (comme des câbles de batterie de calibre 8 ou 4 AWG), vous aurez besoin de connecteurs bout à bout robustes spécialement conçus pour ces calibres. Une mauvaise taille peut entraîner un mauvais sertissage ou un débranchement du fil. La plupart des kits de connecteurs sont disponibles en différentes tailles pour couvrir les calibres courants.

-

Type d'isolation : Choisissez entre des connecteurs bout à bout isolés et non isolés . Les connecteurs bout à bout non isolés sont de simples tubes métalliques sans isolation. Ils sont économiques et polyvalents, mais il est nécessaire de les recouvrir de gaine thermorétractable ou de ruban adhésif après le sertissage pour éviter toute exposition. Les connecteurs bout à bout isolés sont livrés avec une gaine en plastique (vinyle ou nylon). Les connecteurs bout à bout isolés en nylon ont tendance à être plus durables et résistants à la chaleur que ceux en vinyle (le nylon se fend moins facilement). Cependant, les connecteurs standard isolés en vinyle/nylon ne sont pas étanches et peuvent ne pas résister à la corrosion en conditions humides. Si votre application est en extérieur, en mer ou dans un compartiment moteur humide, optez pour des connecteurs bout à bout thermorétractables avec isolation intégrée assurant l'étanchéité. Ils sont parfois commercialisés sous les noms de connecteurs bout à bout de qualité marine , de connecteurs thermorétractables à revêtement adhésif ou d'épissures bout à bout étanches . Ils sont dotés d'une double paroi : une gaine thermorétractable extérieure en polyoléfine et un adhésif intérieur qui fond et scelle sous l'effet de la chaleur. Les connecteurs thermorétractables créent une épissure étanche et isolée une fois chauffés, ce qui est idéal pour les connexions critiques. En résumé, utilisez des connecteurs bout à bout thermorétractables pour tout environnement exposé à l'eau ou à la corrosion, et des connecteurs isolés standard pour le câblage sec à usage général. ( Remarque : Il existe également des connecteurs bout à bout à souder qui combinent soudure et thermorétractable en un seul connecteur. Ils ne nécessitent aucun sertissage, il suffit de les chauffer. Ils peuvent être pratiques, mais dans les zones à fortes vibrations, une connexion sertie est souvent préférable pour une résistance mécanique maximale.)

-

Matériau et qualité : Privilégiez les connecteurs avec un corps en cuivre étamé , car le cuivre offre une excellente conductivité et l'étamage résiste à la corrosion. Les connecteurs bout à bout de haute qualité sont dotés d'un corps sans soudure (sans jointure susceptible de se fissurer) et d'une gaine isolante épaisse. Évitez les connecteurs bon marché, qui peuvent utiliser un métal plus fin ou un plastique plus fragile, susceptible de se fissurer lors du sertissage. De plus, si vous utilisez des connecteurs bout à bout pour le sertissage dans l'automobile ou la marine, assurez-vous qu'ils sont conformes aux normes environnementales (certains peuvent être étiquetés « qualité marine », ce qui signifie qu'ils possèdent une couche adhésive et éventuellement un noyau en cuivre plus épais). Consulter les avis et les spécifications peut vous aider ; par exemple, une marque recommande l'utilisation de cuivre jusqu'à 0,5 mm d'épaisseur dans ses connecteurs bout à bout pour une faible chute de tension et un sertissage robuste.

-

Caractéristiques spéciales : Tenez compte des exigences spécifiques de votre projet. Si vous devez connecter plus de deux fils ensemble (épissure à trois voies), il existe des connecteurs bout à bout à trois voies ou des épissures bout à bout abaisseurs permettant de relier trois fils en un seul (souvent utilisés dans l'automobile pour diviser une connexion). Pour les applications à haute température (comme à proximité de moteurs ou d'équipements produisant de la chaleur), privilégiez les connecteurs bout à bout haute température dotés d'une isolation thermorésistante. Si le câblage est destiné à véhiculer un courant élevé (comme la connexion de deux câbles de batterie), veillez à utiliser un connecteur bout à bout de calibre approprié et l'outil de sertissage adapté. De plus, si vous prévoyez de nombreux travaux de câblage, vous pouvez investir dans un kit de connecteurs bout à bout comprenant des tailles et des types variés afin d'avoir tout sous la main.

-

Kit ou individuel : Pour les bricoleurs ou pour une réparation ponctuelle, vous pouvez acheter un petit paquet contenant les connecteurs nécessaires. Mais si vous travaillez fréquemment sur le câblage, un kit de connecteurs assortis est très pratique. Ces kits comprennent souvent des centaines de connecteurs bout à bout de différentes tailles (rouge, bleu, jaune, etc.), parfois accompagnés d'autres cosses, le tout rangé dans un boîtier. Vous avez ainsi la garantie d'avoir le bon connecteur à portée de main et, à long terme, une solution plus économique. De nombreux kits incluent également une pince à sertir. Par exemple, vous trouverez des kits de connecteurs thermorétractables comprenant des épissures bout à bout, des cosses à œillet et des cosses à fourche, tous dotés d'une isolation thermorétractable, couvrant ainsi un large éventail de besoins de câblage. En cas de doute, un kit de connecteurs bout à bout vous offre la flexibilité nécessaire pour aborder différents projets, des épissures de connecteurs bout à bout à l'ajout de nouvelles cosses.

En prenant en compte ces facteurs – section du fil, type d'isolation, qualité et quantité nécessaires – vous pouvez choisir les connecteurs bout à bout les mieux adaptés à votre application. En général, pour des connexions plus robustes, les connecteurs bout à bout thermorétractables (avec revêtement adhésif) sont fortement recommandés pour tout ce qui est exposé aux intempéries ou critique pour la sécurité. Pour des réparations rapides en intérieur ou des projets de loisirs, des connecteurs bout à bout isolés standard feront l'affaire. Utilisez toujours une pince à sertir adaptée et, en cas de doute, investissez un peu plus dans des connecteurs de qualité marine ou automobile qui garantissent une connexion durable.

👉 Les installations plus rapides commencent avec les connecteurs bout à bout thermorétractables à sertir électriques Haisstronica AWG 22-10 — la solution idéale pour les connecteurs de bornes de fils.

FAQ (Foire aux questions)

Q1 : Comment utiliser un connecteur bout à bout ?

R : Pour utiliser un connecteur bout à bout , dénudez les extrémités des deux fils à raccorder, insérez chaque extrémité dénudée dans le connecteur par les côtés opposés, puis sertissez le connecteur pour le serrer fermement sur les fils. S'il s'agit d'un connecteur bout à bout thermorétractable , chauffez ensuite pour rétrécir l'isolant et sceller la connexion. En résumé : dénudez les fils, insérez-les dans le connecteur bout à bout, sertissez fermement et chauffez si nécessaire. Tirez toujours légèrement sur chaque fil après le sertissage pour vous assurer qu'il est bien fixé. L'utilisation d'un connecteur de la bonne taille et d'un outil de sertissage adapté est la clé du succès. (Pour un guide détaillé étape par étape, consultez les étapes de fonctionnement ci-dessus et pensez à regarder le tutoriel YouTube pour une démonstration visuelle.)

Q2 : Les connecteurs bout à bout sont-ils étanches ou adaptés à une utilisation en extérieur ?

R : Les connecteurs bout à bout isolés standard (en vinyle ou en nylon) ne sont pas étanches en eux-mêmes. Ils assurent une isolation électrique, mais n'empêchent pas l'humidité de pénétrer. Pour une connexion étanche aux intempéries, utilisez des connecteurs bout à bout thermorétractables (également appelés connecteurs bout à bout étanches ou connecteurs bout à bout marins ). Ces connecteurs sont dotés d'une gaine thermorétractable doublée d'adhésif qui, lorsqu'elle est chauffée, crée une étanchéité autour de l'épissure. Correctement sertis et chauffés, ils assurent une connexion étanche IP67 , résistante à l'eau, au sel et à la corrosion. Ces connecteurs sont parfaits pour les applications extérieures, le câblage marin sur les bateaux ou tout environnement humide. En fait, les connecteurs thermorétractables marins et les connecteurs bout à bout électriques thermorétractables sont spécialement conçus pour ces situations. Si vous ne possédez que des connecteurs bout à bout classiques, vous pouvez les rendre étanches en ajoutant une gaine thermorétractable sur le sertissage et éventuellement de la graisse diélectrique. Il est toutefois plus simple d'utiliser le type thermorétractable pré-isolé. Alors oui , les connecteurs bout à bout peuvent être rendus étanches, mais seuls les connecteurs bout à bout thermorétractables (ou à épissure bout à bout thermorétractables ) le sont intrinsèquement. Vérifiez toujours la description du produit : recherchez des termes tels que « à revêtement adhésif » , « qualité marine » ou « thermorétractable » pour les connecteurs adaptés à une utilisation en extérieur.

Q3 : Puis-je utiliser des connecteurs à épissure bout à bout pour des fils de gros calibre ou des câbles de batterie ?

R : Oui, il existe des connecteurs bout à bout (épissures bout à bout) conçus pour les fils de gros calibre (tels que les câbles de batterie automobile, 8 AWG, 4 AWG, etc.), mais il est essentiel de choisir des connecteurs bout à bout robustes et de disposer de l'outil de sertissage adapté. Ces connecteurs robustes ne sont souvent pas étiquetés par couleur ; ils sont simplement dimensionnés par calibre (par exemple, connecteur bout à bout 4 AWG ou épissure bout à bout 8 AWG ). Ils sont généralement en cuivre étamé épais et peuvent ne pas être pré-isolés (on utilise souvent une gaine thermorétractable séparée pour isoler la jonction après le sertissage). Pour sertir un connecteur aussi gros, une pince à sertir manuelle classique ne suffit pas ; il faut généralement un outil spécialisé comme une pince à sertir à marteau ou une presse à sertir hydraulique pour appliquer une force suffisante. Lorsqu'elle est réalisée correctement, l'épissure bout à bout de câbles de gros calibre est efficace (par exemple, pour raccorder un câble de batterie sectionné). Utilisez toujours un connecteur adapté au calibre et au courant du câble. Par exemple, un connecteur de câble de batterie pour fil de calibre 2 AWG supportera un ampérage élevé, mais doit être serti très solidement. Il est également recommandé de sceller le sertissage avec une gaine thermorétractable résistante pour assurer la décharge de traction et l'isolation. En résumé, les connecteurs bout à bout peuvent être utilisés sur des fils épais , mais assurez-vous d'utiliser un connecteur et une pince de sertissage de gros calibre adaptés. Dans le cas contraire, la connexion peut être fragile. En cas de doute (ou pour des connexions critiques), consultez un expert, envisagez d'utiliser un connecteur à pince mécanique ou de faire épisser le câble par un professionnel. Cependant, pour la plupart des projets de bricolage concernant les panneaux solaires, l'autoradio ou les batteries, des connecteurs bout à bout disponibles en kit pour des calibres tels que 8 AWG, 4 AWG, etc., feront l'affaire s'ils sont correctement installés.

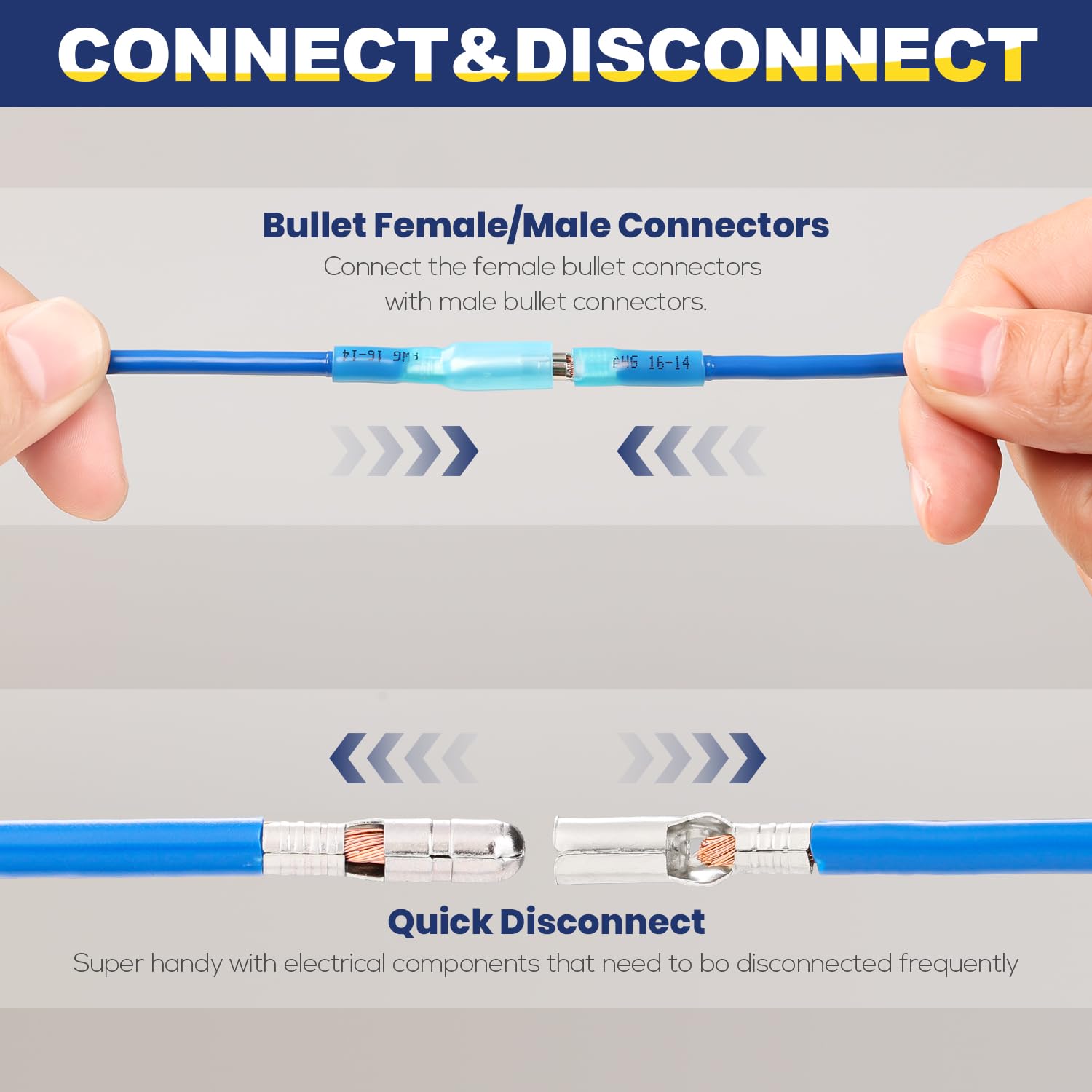

Q4 : Quelle est la différence entre un connecteur bout à bout et d'autres connecteurs tels que les cosses à balle, à fourche ou à anneau ?

R : Un connecteur bout à bout sert spécifiquement à joindre deux extrémités de fil de manière permanente (enfin, semi-permanente ; il est conçu pour rester serti et ne pas être déconnecté à plusieurs reprises). En revanche, d'autres connecteurs ont des fonctions différentes : par exemple, un connecteur cylindrique est une connexion en deux parties (mâle et femelle) qui peut être branchée et débranchée, souvent utilisée dans l'automobile pour des déconnexions rapides. Un connecteur à fourche (et son homologue, la cosse à fourche) sert à connecter des fils à des composants (comme des bornes de haut-parleur ou des interrupteurs) et peut être glissé/dévissé. Un connecteur à cosse à anneau est serti sur un fil pour permettre de le boulonner à une vis ou un goujon (généralement pour les bornes de terre ou de batterie). Ce sont tous des types de connecteurs de cosses de fil , mais ils ne servent pas à épisser deux fils bout à bout. Le connecteur bout à bout (épissure bout à bout) a la particularité de joindre uniquement des fils. Imaginez : si vous avez besoin de rallonger un fil, vous utiliserez un connecteur bout à bout ; Pour raccorder un fil à une borne à vis, utilisez une cosse à anneau ; pour une jonction déconnectable, vous pouvez utiliser des cosses à œillet ou à fourche. Chacune a son utilité. On confond parfois les termes ; par exemple, « cosses à œillet bout à bout » n'est pas un terme exact ; les cosses à œillet sont des connecteurs distincts. En résumé, les cosses à œillet/épissures servent à épisser les fils en ligne, tandis que les cosses à œillet, à fourche, à œillet, etc., servent à terminer un fil pour le fixer ou permettent le branchement/débranchement des connecteurs. Selon votre projet, vous pouvez utiliser une combinaison de ces deux options (par exemple, épisser bout à bout une longueur de fil supplémentaire, puis placer une cosse à œillet à l'extrémité pour la connexion à une batterie).

Q5 : Puis-je réutiliser un connecteur bout à bout ou le dévisser si j'ai fait une erreur ?

R : Les connecteurs bout à bout sont généralement destinés à un usage unique. Une fois sertis, le corps métallique se déforme et il est très difficile de retirer un fil ou de le réutiliser sans compromettre son intégrité. En pratique, en cas d'erreur (par exemple, sertissage du mauvais fil ou modification nécessaire), la méthode habituelle consiste à couper le connecteur et à en sertir un nouveau. Techniquement, on pourrait essayer d'ouvrir le connecteur serti avec une pince, mais cela l'endommagerait presque toujours et le sertissage ne serait pas aussi fiable la deuxième fois. Les connecteurs neufs sont peu coûteux ; il est donc préférable d'en utiliser un neuf pour garantir une connexion fiable. De plus, retirer un fil serti peut également endommager les brins. Par conséquent, même si, en cas de besoin, vous pouvez réutiliser un connecteur bout à bout avec précaution , cela est déconseillé . Pour une sécurité et des performances optimales, utilisez un connecteur neuf pour chaque nouvelle utilisation. Conseil de pro : gardez toujours quelques épissures bout à bout de rechange à portée de main (votre kit de connecteurs bout à bout en contient suffisamment) au cas où vous auriez besoin d'un deuxième essai. Et n'oubliez pas, si vous avez serti et surtout si vous avez thermorétracté le connecteur, il est scellé et doit être traité comme permanent - pour le défaire, vous le couperiez.

👉 Faites confiance aux connecteurs bout à bout thermorétractables à sertir électriques Haisstronica AWG 22-10 lorsque vous avez besoin d'un fil de connecteur bout à bout bien fait.

Où acheter des connecteurs bout à bout de qualité (Guide d'achat)

Disposer des connecteurs bout à bout adaptés peut vous faire gagner du temps et vous simplifier la vie lors de vos projets électriques. Si vous recherchez une solution pratique et tout-en-un, pensez à un kit de connecteurs bout à bout thermorétractables . Nous vous recommandons le kit de connecteurs bout à bout thermorétractables Haisstronica (AWG 22-10) , présenté dans un flacon pratique et couvrant une large gamme de sections de fils. Ce kit comprend des connecteurs bout à bout thermorétractables à sertir de haute qualité, doublés d'adhésif pour une étanchéité optimale, dotés d'un code couleur pour une identification facile des tailles et fabriqués en cuivre étamé pour une conductivité maximale. Il est idéal pour les applications automobiles, marines et électriques générales.

👉 Recommandation d'achat : Découvrez les connecteurs bout à bout thermorétractables Haisstronica AWG 22-10 (bouteille) pour un ensemble fiable d'épissures bout à bout qui répondra à la plupart de vos besoins en câblage. Avec ce kit de connecteurs , vous disposerez de connecteurs bout à bout rouges, bleus et jaunes prêts à l'emploi pour tous vos travaux : réparation du câblage de votre voiture, installation de composants électroniques pour bateau ou simple câblage d'une nouvelle chaîne stéréo. Avoir un tel kit sur votre établi vous garantit toujours la taille de connecteur adaptée, et la fonction thermorétractable garantit la solidité et la durabilité de chaque connexion.

Maintenant que vous savez ce que sont les connecteurs bout à bout , comment les utiliser et choisir le bon type, vous pouvez aborder votre prochain projet de câblage en toute confiance. Ces petits connecteurs discrets simplifient considérablement les travaux électriques. Bons travaux de raccordement bout à bout !

Nos meilleurs choix conviviaux

Obtenez des sertissages d'une solidité à toute épreuve grâce à un cuivre étamé à 99,9 % résistant à l'oxydation et aux étincelles électriques. Le manchon adhésif se rétracte 3:1 pour encapsuler le joint : étanche, résistant à l'abrasion et durable. Ces connecteurs thermorétractables sont les connecteurs bout à bout les plus fiables pour les professionnels.

👉 Pour le câblage des connecteurs bout à bout, choisissez les connecteurs bout à bout thermorétractables à sertir électriques Haisstronica AWG 22-10 et terminez en force.