1. Common Issues When Choosing Heat Shrink Connectors

Have you ever faced these problems?

-

Frequent circuit shorting due to exposed connections that lead to moisture or oxidation?

-

Uneven shrinkage causing poor sealing and eventual circuit failure?

-

Insufficient temperature resistance leading to brittle and cracked heat shrink tubing?

The root cause of these issues might be choosing the wrong heat shrink connectors!

2. Five Key Factors for Choosing the Right Heat Shrink Connectors

When selecting heat shrink connectors, pay close attention to these five critical factors:

(1) Wire Gauge Compatibility

The size of the heat shrink connector should match the wire diameter for a secure fit after shrinking.

-

Too large: Poor sealing and ineffective insulation.

-

Too small: Difficult to install and may hinder electrical conductivity.

Recommended Wire Gauge Selection Guide:

| Wire Gauge (AWG) | Recommended Heat Shrink Tube Diameter (Before Shrinking) |

|---|---|

| 20-16 | 3.2mm |

| 16-14 | 4.8mm |

| 12-10 | 6.4mm |

| 8-6 | 9.5mm |

For a full range of heat shrink connectors, check out our collection here: Haisstronica Heat Shrink Connectors

(2) Shrink Ratio

The shrink ratio determines how much the tubing contracts when heated.

-

Common shrink ratios: 2:1, 3:1, 4:1

-

Higher shrink ratios (such as 3:1) are ideal for irregular-shaped connections, ensuring a tighter seal.

Check out our high-ratio heat shrink connectors for maximum versatility: Shop Now

(3) Insulation & Safety Ratings

One of the key roles of heat shrink connectors is to provide insulation and protection. Look for:

-

Voltage rating (e.g., 600V, 1000V)

-

Insulation material (such as cross-linked polyolefin)

-

UL certification (e.g., VW-1 flame retardant standard)

Our UL-certified connectors provide the best insulation and flame resistance: Browse Products

(4) Temperature Resistance

The required temperature resistance varies depending on the application:

-

General household/low-power circuits: -40°F to +221°F (-40°C to +105°C)

-

Automotive, motors, and outdoor environments: -67°F to +257°F (-55°C to +125°C) or higher

For high-temperature-resistant connectors, explore our premium selection: Click Here

(5) Corrosion Resistance

If your application involves moisture, oil, or chemicals, choose corrosion-resistant connectors such as:

-

Waterproof type (with adhesive inner layer, suitable for automotive wiring harnesses)

-

Oil & acid-resistant type (for industrial applications)

Our waterproof and corrosion-resistant connectors ensure longevity and durability: Find Yours Here

3. Easy Heat Shrink Connector Selection Process

To help you quickly find the right heat shrink connector, follow this simple process:

-

Measure wire gauge (Use a caliper for accuracy)

-

Determine environmental needs (High temperature, waterproof, chemical-resistant?)

-

Choose the right shrink ratio (2:1, 3:1, or 4:1)

-

Confirm insulation and voltage rating (UL certification, required voltage level)

-

Match with recommended products

🛒 Ready to buy the perfect heat shrink connectors? Browse our complete collection at Haisstronica!

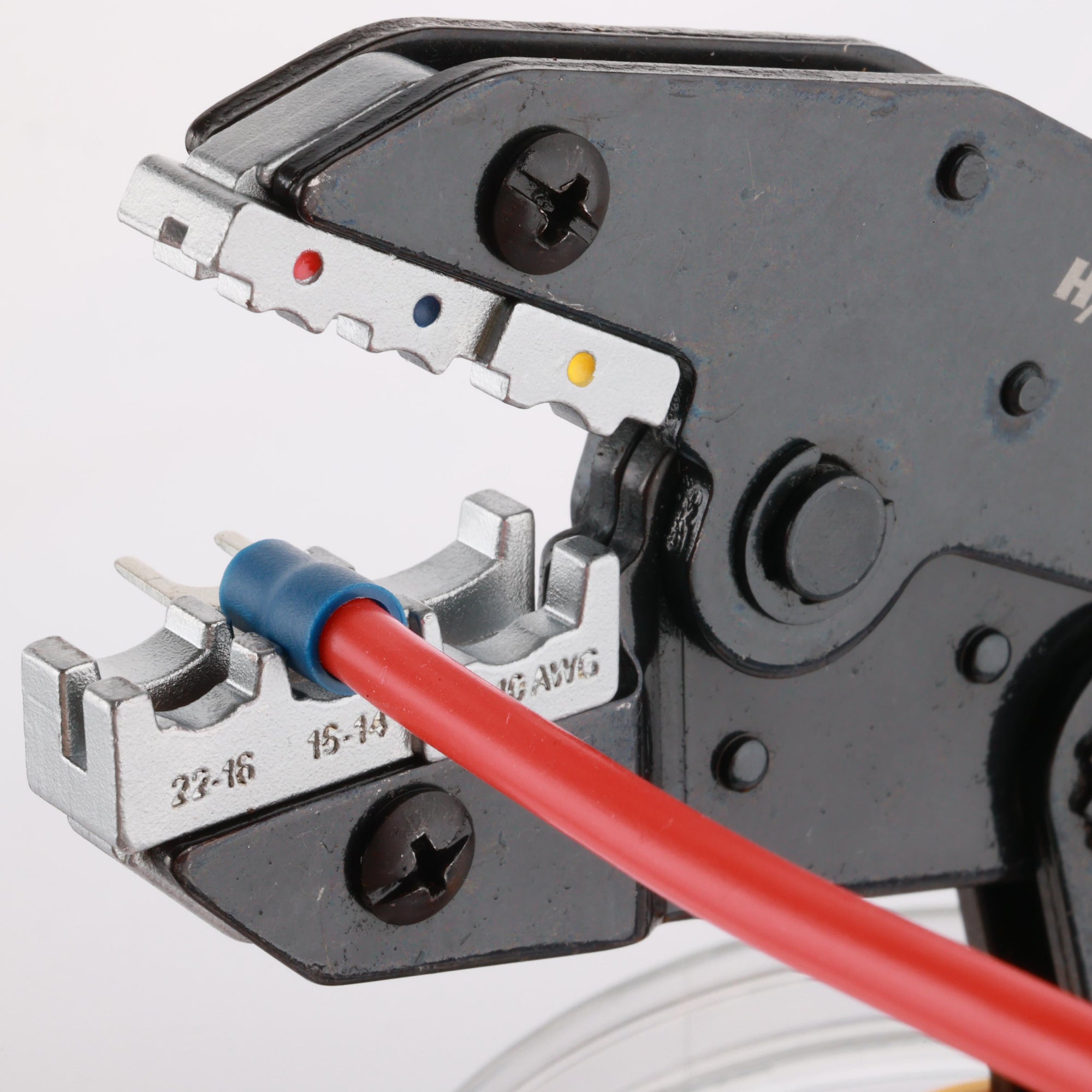

📷 Need Visual Guidance?

We have included product images, instructional graphics, and comparison charts to help you make the best choice. Click here for detailed product descriptions.

🔍 Still Not Sure?

Contact us for expert advice on choosing the right heat shrink connectors for your needs: Get Help Here.

1 comment

Joe Ragsdale

I’d like to be able to use one size of shrink tube for 3 conductor # 14 SO CORD at the breakout point as well as the terminal end of individual conductors. If it will fit both areas of the cord and conductors in double wall shrink tube.

I’d like to be able to use one size of shrink tube for 3 conductor # 14 SO CORD at the breakout point as well as the terminal end of individual conductors. If it will fit both areas of the cord and conductors in double wall shrink tube.